Natural rubber/silicone rubber/alumina ternary thermally conductive composite material and preparation method thereof

A thermally conductive composite material and silicone rubber technology, applied in the rubber field, can solve problems such as unsatisfactory thermal conductivity, and achieve the effects of improving utilization efficiency, decreasing tensile strength, excellent aging resistance and adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

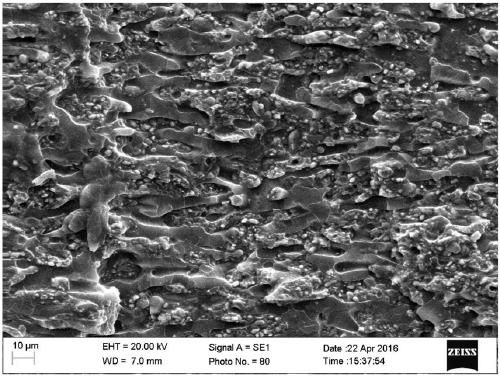

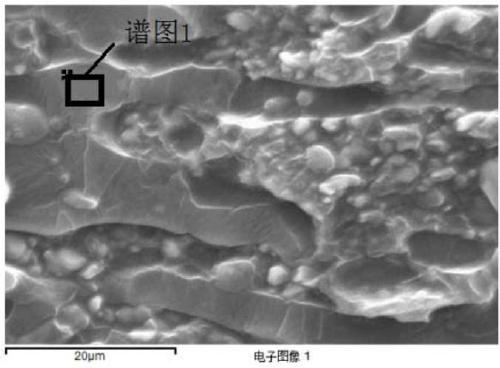

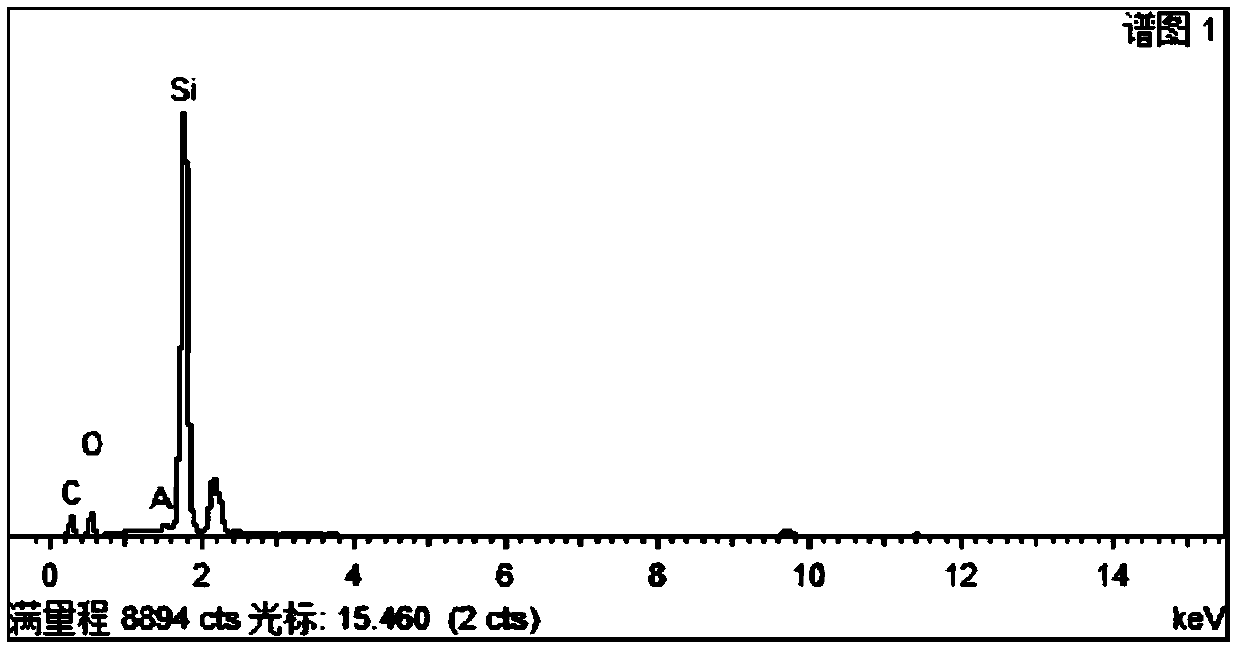

Image

Examples

Embodiment 1

[0037] A high thermal conductivity natural rubber / silicone rubber / alumina ternary thermal conductivity composite material, its formula and preparation process are as follows:

[0038] The following formula is in parts by weight, 60 parts of natural rubber, 40 parts of silica gel, 180 parts of aluminum oxide, 2 parts of sulfur, 1 part of accelerator selection CZ, 4 parts of active agent zinc oxide, 0.8 parts of stearic acid, 1.5 parts of anti-aging agent, 2 parts of peroxide vulcanizing agent BIBP.

[0039] The preparation process is as follows: (1) Masterbatch: The masterbatch preparation process is carried out in an internal mixer with an initial temperature of 20° C. and a rotation speed of 40 rpm. The feeding order of natural rubber masterbatch is: natural rubber is added at the beginning, and sulfur, active agent, and accelerator are added in order after 2 minutes; the feeding order of silica gel masterbatch is: silicone rubber is added at the beginning, 1-2 minutes Then ...

Embodiment 2-4

[0043] A high thermal conductivity natural rubber / silicone rubber / alumina ternary thermal conductivity composite material, its formula and preparation process are as follows:

[0044] The following formula is in parts by weight: 50 parts of natural rubber, 50 parts of silica gel, 80-300 parts of aluminum oxide, 1 part of sulfur, 0.5 parts of accelerator TMTD, 3 parts of active agent zinc oxide, 0.5 parts of stearic acid, anti-aging agent 1.5 parts, peroxide curing agent BIBP1.5 parts.

[0045] The preparation process is as follows: (1) Masterbatch: The masterbatch preparation process is carried out in an internal mixer with an initial temperature of 40° C. and a rotational speed of 50 rpm. The feeding order of natural rubber masterbatch is: natural rubber is added at the beginning, and sulfur, active agent, and accelerator are added in order after 2 minutes; the feeding order of silica gel masterbatch is: silicone rubber is added at the beginning, 1-2 minutes Then add the per...

Embodiment 5-7

[0053] A high thermal conductivity natural rubber / silicone rubber / alumina ternary thermal conductivity composite material, its formula and preparation process are as follows:

[0054] The following formula is in parts by weight, 40 parts of natural rubber, 60 parts of silica gel, 220 parts of aluminum oxide, 1 part of sulfur, 1 part of accelerator selection NS, 3 parts of active agent zinc oxide, 1 part of stearic acid, 2 parts of anti-aging agent, over Oxide curing agent BIBP1.8 parts.

[0055] The preparation process is as follows: (1) Masterbatch: The masterbatch preparation process is carried out in an internal mixer with an initial temperature of 40° C. and a rotation speed of 50 rpm. The feeding order of natural rubber masterbatch is: natural rubber is added at the beginning, and sulfur, active agent, and accelerator are added in order after 2 minutes; the feeding order of silica gel masterbatch is: silicone rubber is added at the beginning, 1-2 minutes Then add the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com