A kind of method utilizing solar energy to prepare transition metal oxide/carbon composite material

A technology of carbon composite materials and transition metals, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of cumbersome preparation steps and high energy consumption, and achieve easy large-scale production, low energy consumption, and experimental The method is simple and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

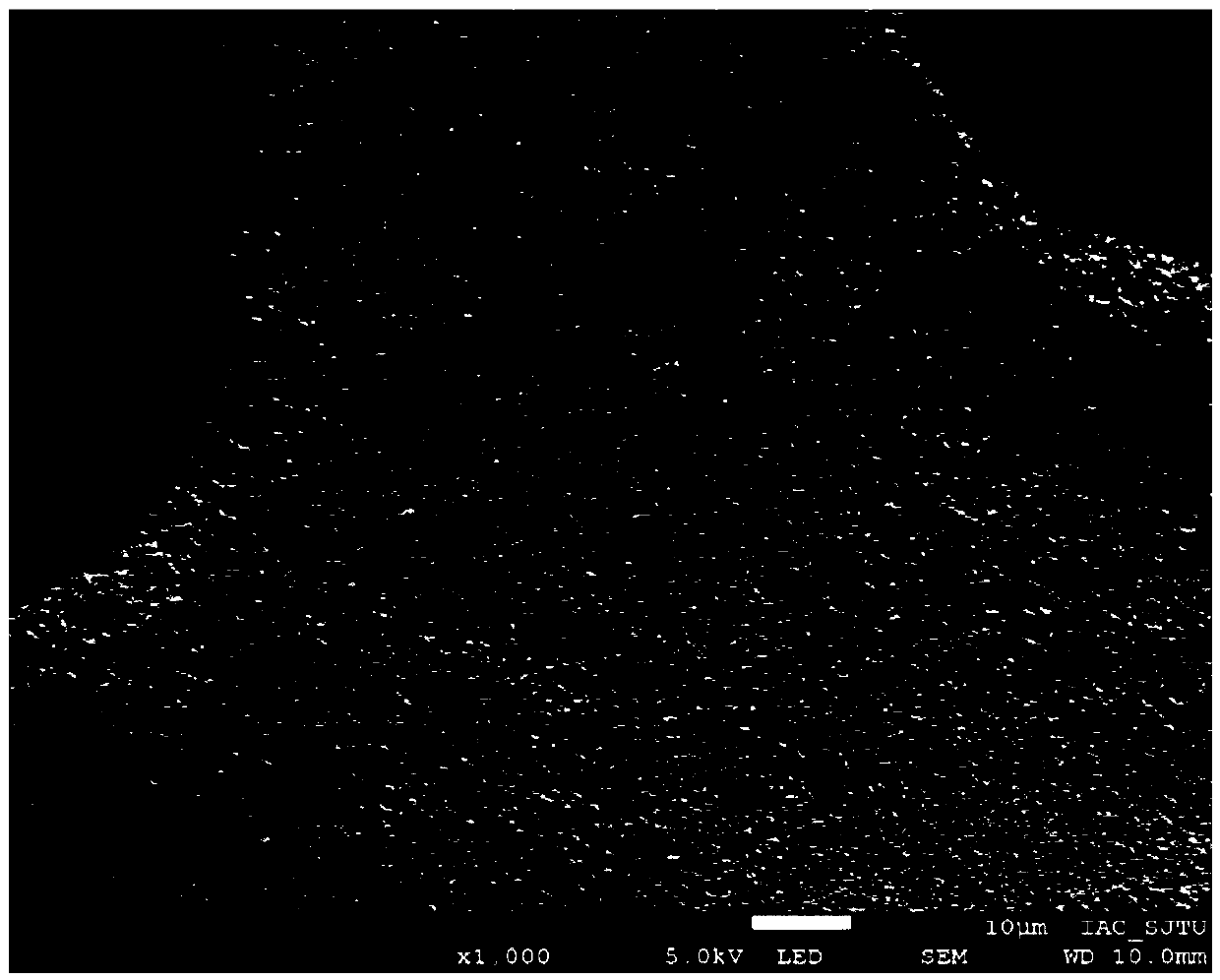

Image

Examples

Embodiment 1

[0019] Weigh 2 g of glucose, add it into 20 mL of deionized water, and disperse by ultrasonic to form a homogeneous solution, and ultrasonic for 5 minutes. The nickel foam was cut into small pieces of 1 cm × 2 cm, ultrasonically cleaned with acetone, ethanol, and deionized water, and then immersed in the prepared solution, and a small amount of solution was left on the surface of the nickel foam by pulling method. Use the solar cooker to focus the solar beam to heat the sample, the heating temperature is 450°C ± 10°C, and the heating time is 1 minute. After the reaction, the nickel oxide / carbon composite material was washed in deionized water, dried, and stored for later use.

Embodiment 2

[0021] Weigh 2 g of glucose, add it into 20 mL of deionized water, and disperse by ultrasonic to form a homogeneous solution, and ultrasonic for 5 minutes. The copper foam was cut into small pieces of 1 cm × 2 cm, ultrasonically cleaned with acetone, ethanol, and deionized water, and then immersed in the prepared solution, and a small amount of solution was left on the surface of the copper foam by pulling method. Use the solar cooker to focus the solar beam to heat the sample, the heating temperature is 450°C ± 10°C, and the heating time is 3 minutes. After the reaction, the copper oxide / carbon composite material was washed in deionized water, dried, and stored for later use.

Embodiment 3

[0023] Weigh 2 g of sucrose, add it into 20 mL of deionized water, and disperse by ultrasonic to form a homogeneous solution. Ultrasonic for 5 minutes. Cut the iron sheet into small pieces of 1cm×2cm, polish the surface with sandpaper, then ultrasonically clean it with acetone, ethanol, and deionized water, then immerse it in the prepared solution, and use the pulling method to leave a small amount of solution on the surface of the iron sheet . Use the solar cooker to focus the solar beam to heat the sample, the heating temperature is 450°C ± 10°C, and the heating time is 1 minute. After the reaction, the iron oxide / carbon composite material was washed in deionized water, dried, and stored for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com