A pickled bacon fresh-keeping method utilizing a natural coating liquid

A fresh-keeping method and a technology of cured meat, applied in the direction of preserving meat/fish by coating a protective layer, preserving meat/fish through freezing/cooling, etc., can solve the problems of no fresh-keeping instructions for cured meat, excessive coating material components, and handling Trouble and other problems, to achieve good results, simple operation, quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A fresh-keeping method of cured bacon coated with a film, comprising the steps of:

[0021] 1) Production of cured bacon: After the raw meat is cleaned, cut into pieces, pickled, cold-smoked, baked, and cooled according to conventional methods, the required cured bacon product is obtained.

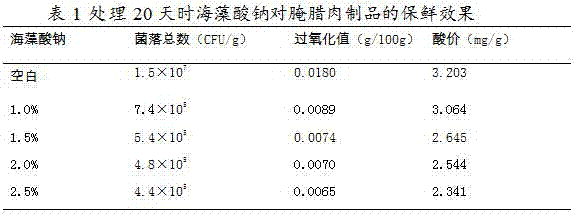

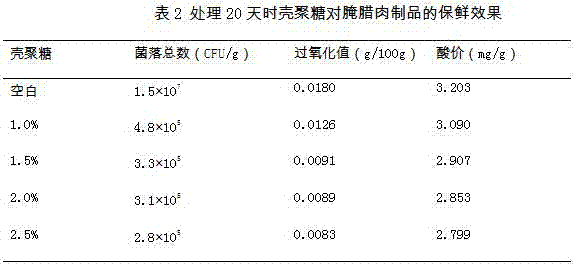

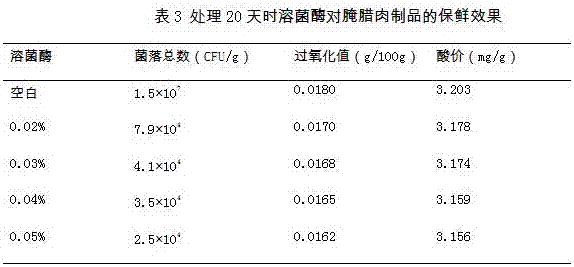

[0022] 2) Preparation of coating solution: The sodium alginate solution was prepared by adding 4% sodium alginate and 4% glycerin, stirring continuously while heating until it was completely dissolved, and degassing by ultrasonication for 50 minutes for later use; The polysan solution was prepared by adding 3% chitosan. During chitosan treatment, 3% acetic acid solution was added, and the bubbles were degassed by ultrasonication for 50 min. The cooled sodium alginate and chitosan were evenly fused After that, add lysozyme at a ratio of 0.09%.

[0023] 3) Dipping: Put the sliced cured meat into the natural coating solution for 0.5-5 minutes, so that the cured meat products are ful...

Embodiment 2

[0028] 1) Production of cured bacon: After the raw meat is cleaned, cut into pieces, pickled, cold-smoked, baked, and cooled according to conventional methods, the required cured bacon product is obtained.

[0029] 2) Preparation of coating solution: This new type of film was prepared by using sodium alginate as the main material of the film, chitosan as a stabilizer, and lysozyme as a natural antibacterial agent. Among them, the sodium alginate solution was prepared as follows: adding 2% sodium alginate and 3% glycerin, stirring continuously while heating until completely dissolved, and degassing by ultrasonication for 40 min for later use. The chitosan solution was prepared as follows: the amount of chitosan added was 2%, 1% acetic acid solution was added during the chitosan treatment process, and the bubbles were removed by ultrasonication for 40 min. After the cooled sodium alginate and chitosan are evenly fused, add 0.05% lysozyme.

[0030] 3) Dipping: Put the sliced c...

Embodiment 3

[0035] 1) Production of cured bacon: After the raw meat is cleaned, cut into pieces, pickled, cold-smoked, baked, and cooled according to conventional methods, the required cured bacon product is obtained.

[0036] 2) Preparation of coating solution: This new type of film was prepared by using sodium alginate as the main material of the film, chitosan as a stabilizer, and lysozyme as a natural antibacterial agent. Among them, the sodium alginate solution was prepared as follows: adding 3% sodium alginate and 1.5% glycerin, stirring continuously while heating until completely dissolved, and degassing by ultrasonication for 30 min for later use. The preparation of chitosan solution is as follows: the amount of chitosan added is 1%, and 1.5% acetic acid solution needs to be added during the chitosan treatment process. After the chitosan solution is in the state of film-forming liquid, it is ultrasonicated for 30 min to remove air bubbles for later use. After the cooled sodium alg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com