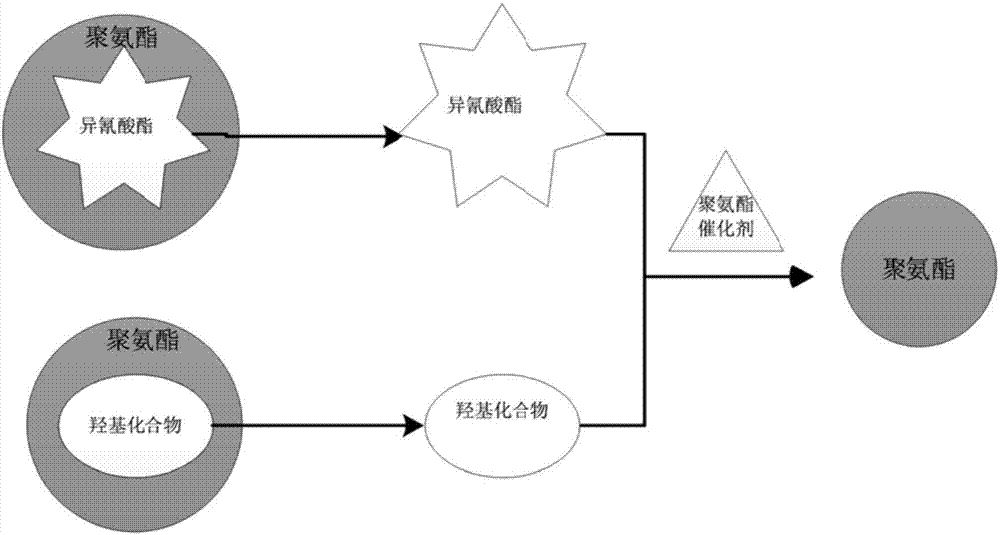

Polyurethane mixed microcapsule and preparation method thereof

A technology of ester microcapsules and polyurethane, which is applied in the field of microcapsule preparation, can solve problems such as poor repair effect and poor heat resistance, and achieve good uniformity, good compatibility, good heat resistance and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

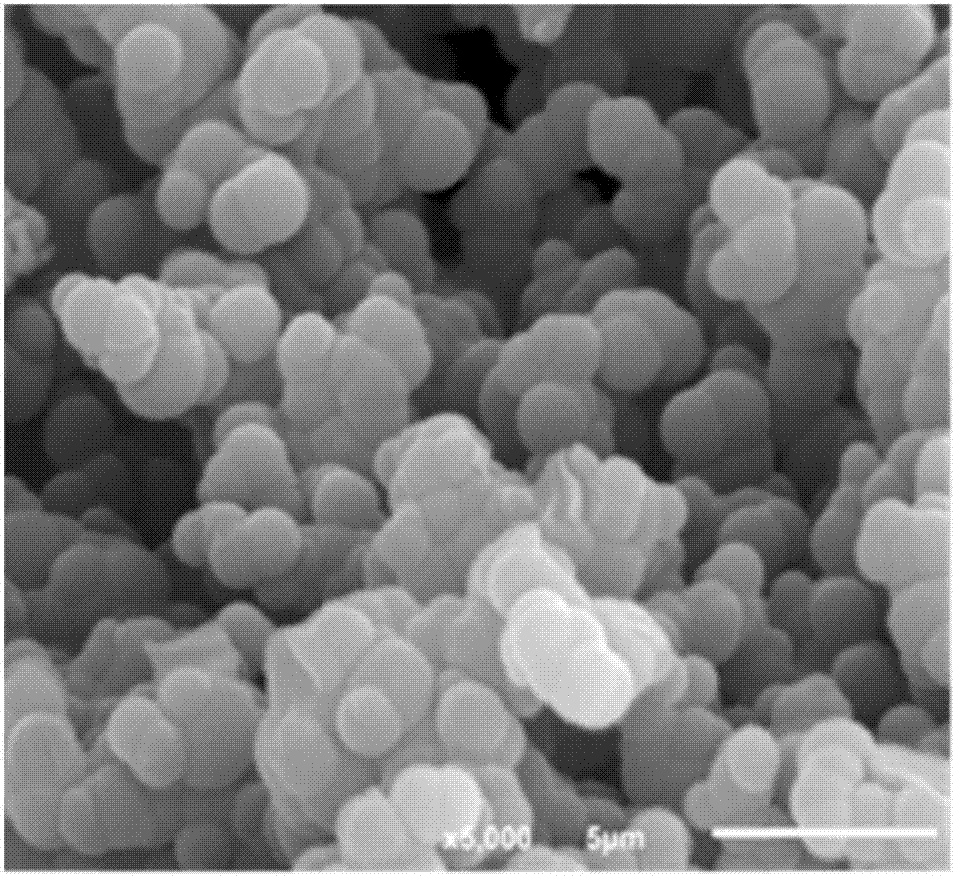

Examples

Embodiment 1

[0042] The preparation method of polyurethane mixed microcapsules, comprises the following steps:

[0043] S1: Preparation of polyurethane-coated isocyanate microcapsules:

[0044] Take 80ml of silicone oil for distillation to remove the water and living wave hydrogen atoms, then take 17.4g of toluene diisocyanate (TDI) and disperse dropwise in the silicone oil to obtain the first dispersion, stir the first dispersion at 600r / min until the dispersion appears fine Then add 3g of ethylene glycol dropwise to the first dispersion liquid under the condition of 600r / min stirring, after reacting for 1 hour, add 25ml acetone to the first dispersion liquid to carry out polyurethane polymerization reaction, TDI and Ethylene glycol is polymerized to form a polyurethane wall layer, and TDI is wrapped by the polyurethane wall layer to form an isocyanate core layer. After the polymerization reaction is completed, it is washed in turn, suction filtered, and naturally air-dried to obtain polyur...

Embodiment 2

[0050] The preparation method of polyurethane mixed microcapsules, comprises the following steps:

[0051] S1: Preparation of polyurethane-coated isocyanate microcapsules:

[0052] Take 80ml of silane for distillation to remove the water and active hydrogen atoms, then take 15g of diphenylmethane diisocyanate (MDI) and disperse it dropwise in silane to obtain the first dispersion, and stir the first dispersion at 2000r / min until dispersed Fine particle-like droplets appeared in the liquid, and then 5g of diethylene glycol was added dropwise to the first dispersion under the condition of stirring at 2000r / min. After reacting for 1 hour, 25ml of acetone was added to the first dispersion to carry out polyurethane polymerization. , MDI and diethylene glycol are polymerized to form a polyurethane wall layer, and the MDI is wrapped by the polyurethane wall layer to form an isocyanate core layer. After the polymerization reaction is completed, it is washed in turn, suction filtered, ...

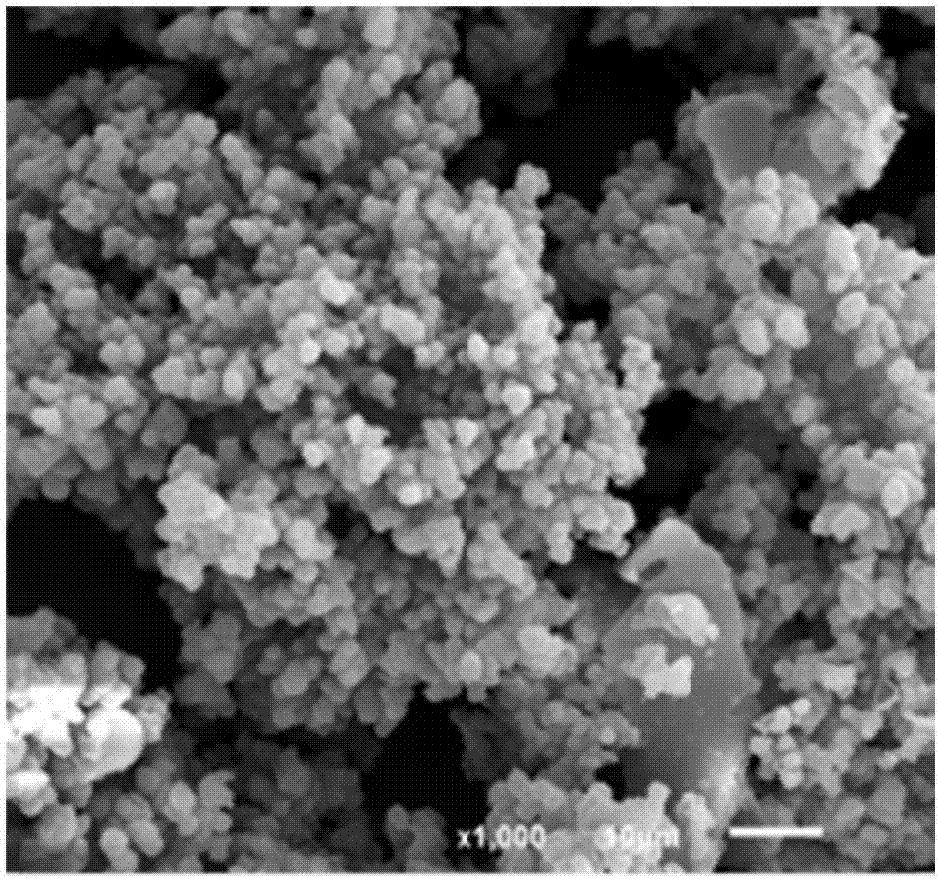

Embodiment 3

[0058] The preparation method of polyurethane mixed microcapsules, comprises the following steps:

[0059] S1: Preparation of polyurethane-coated isocyanate microcapsules:

[0060] Take 80ml of cyclohexane for distillation to remove the water and living wave hydrogen atoms, then take 20g of diisocyanate and disperse dropwise in cyclohexane to obtain the first dispersion, stir the first dispersion at 1000r / min until the dispersion appears fine Granular micro-droplets, then add 2g of 1,4-butanediol dropwise to the first dispersion liquid under the condition of 1000r / min stirring, after reacting for 1 hour, add 25ml acetone to the first dispersion liquid to carry out polyurethane polymerization reaction , diisocyanate and 1,4-butanediol are polymerized to form a polyurethane wall layer, and the diisocyanate is wrapped by the polyurethane wall layer to form an isocyanate core layer. After the polymerization reaction is completed, it is washed in sequence, suction filtered, and nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com