Although the prediction control method improves the accuracy of steel breakout prediction to a certain extent and reduces the number of false alarms, it does not take into account the

response time and timeliness of the bonding alarm, especially when the temperature amplitude inspection is used. The identification and alarm time of a single

thermocouple bonding temperature waveform is late, which may not be able to report the bonding behavior in time. If the alarm is late, even if the

machine is

shut down directly, it cannot guarantee the repair of the bonding crack without steel leakage. If it is earlier The alarm can be maintained at a low shell

healing rate to repair the bonded crack without stopping the

machine or stopping pouring, which increases unnecessary

operation time, reduces production efficiency and increases equipment loss.

[0005]

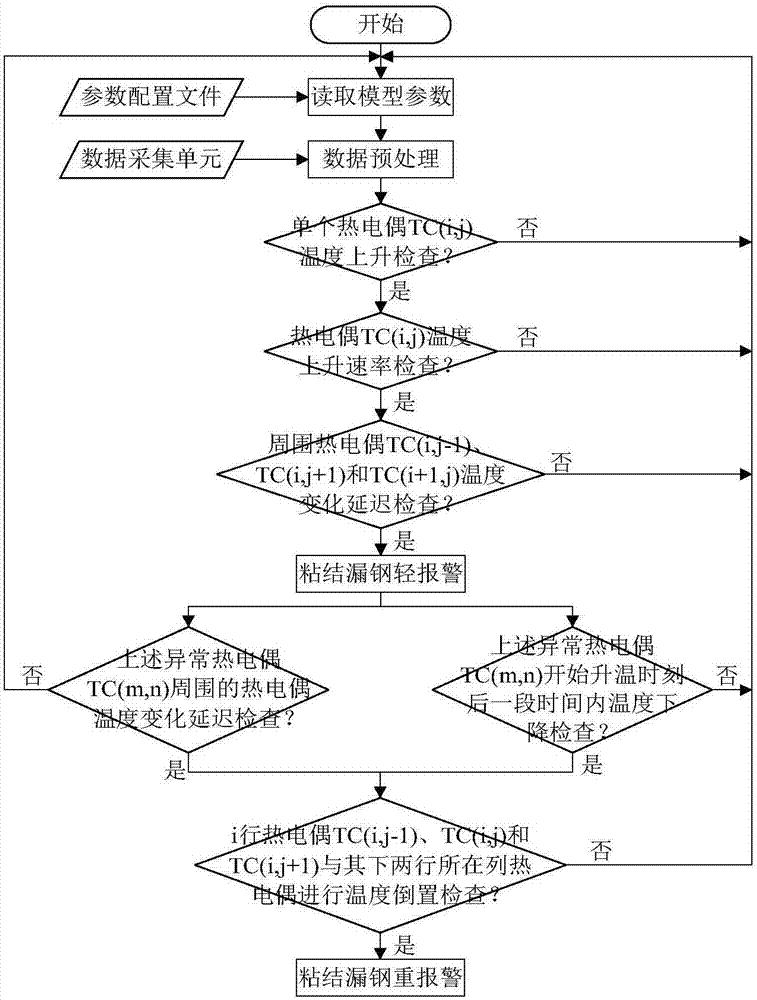

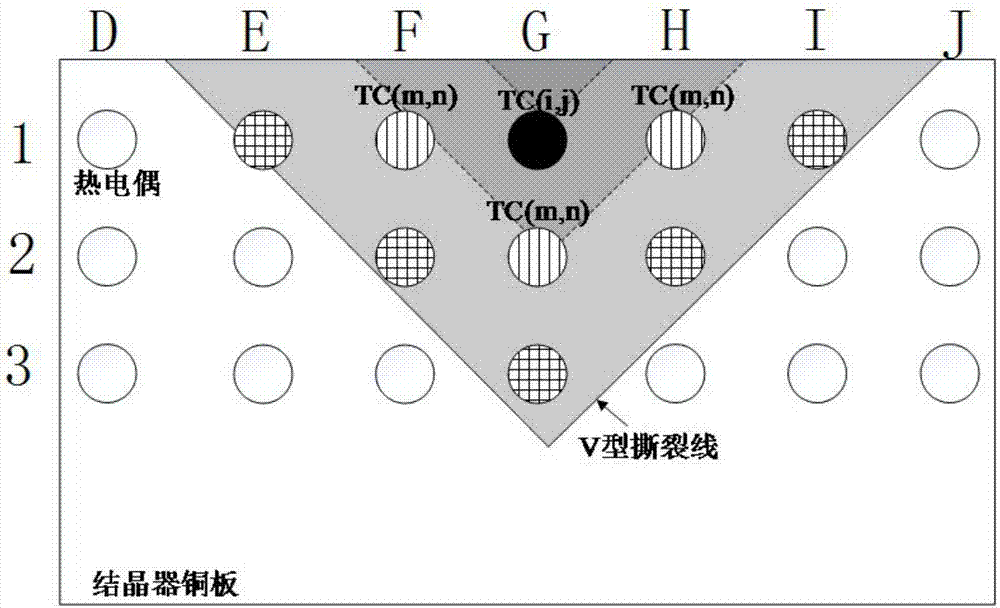

Patent document CN102825234A discloses a method for judging and alarming bonded breakouts. The method for judging and alarming is based on the time-

lag of the temperature of multiple rows of thermocouples in space and the characteristics of

temperature curve crossing (ie, temperature inversion). The typical temperature change waveform mode or the theoretical temperature change waveform mode is designed, but in the actual production process, not all bonding temperature change waveform

modes will show the "temperature inversion" phenomenon, and the actual production is due to the

liquid steel level fluctuations, Influenced by factors such as mold flux performance,

molten steel flow, and thermocouple failure, temperature inversion of the upper and lower thermocouples on the

copper plate of the mold often occurs, or in non-bonding conditions such as unsteady casting and thermocouple failure, there are often relatively high Large thermocouple temperature fluctuations are also prone to temperature inversion, so the design of this method undoubtedly increases the probability of false positives and negative negatives

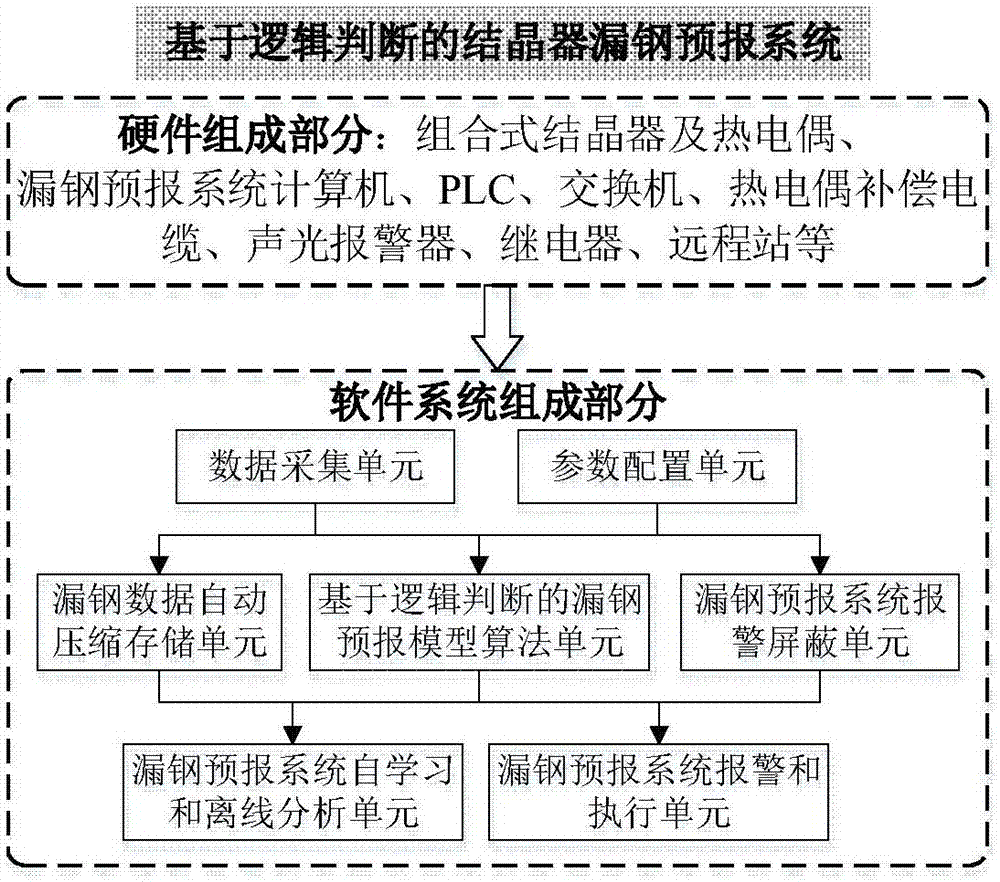

[0006] A comprehensive investigation of the current domestic and foreign breakout forecasting systems and logical judgment forecasting methods found that the main problems are as follows: (1) The failure of the thermocouple itself caused abnormal changes in the measured temperature, which affected the breakout forecasting

algorithm and system judgment

For example: due to the quality problem of the thermocouple itself, the performance is unstable or the thermocouple loses its thermoelectric characteristics, and the

temperature curve fluctuates too much; the thermocouple is assembled in the wrong way or the seal is not good, resulting in a large deviation between the measured temperature and the actual temperature after oil or cooling water enters, Make the

temperature curve fluctuate;

distortion occurs during the transmission of the thermocouple

signal, making the temperature curve fluctuate

(2) Under unsteady casting conditions such as start of pouring,

tundish replacement, and final pouring, the temperature of the thermocouple will be greatly affected, and false alarms of the

algorithm will also increase; The temperature waveform of the thermocouple in the junction process can reduce false alarms, but in the actual process, sometimes the temperature change of the thermocouple under unsteady conditions is very close to the temperature waveform of the

bonding process, which increases the difficulty of the design of the breakout prediction model

(3) Some important parameters of the logic judgment

algorithm depend on the specific process and equipment conditions. With the change of casting conditions such as equipment loss, material replacement, steel type and mold

slag, the algorithm becomes more and more inaccurate

(4) Although the characteristics of single thermocouple temperature change with time during bonding and the "

time lag" and "temperature inversion" characteristics of the temperature change of multiple rows and rows of thermocouples in space have become

consensus, they are the basis for the design of breakout prediction logic algorithm , although the logic judgment algorithms designed according to these characteristics are different, but the comprehensive consideration of forecast accuracy and alarm time is insufficient

[0007] In summary, how to overcome the shortcomings of the continuous casting breakout prediction method and device in the prior art in terms of prediction accuracy and alarm timeliness is a technical problem that needs to be solved urgently in the prior art

Login to View More

Login to View More  Login to View More

Login to View More