Imitated Wukang (Chinese character) ancient stone formula and preparation technology thereof

A technology of formula and stone powder is applied in the field of imitation Wukang ancient stone formula and its preparation technology, which can solve the problems of difference of finished products and complicated preparation technology, and achieve the effects of dense structure, high structure strength and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

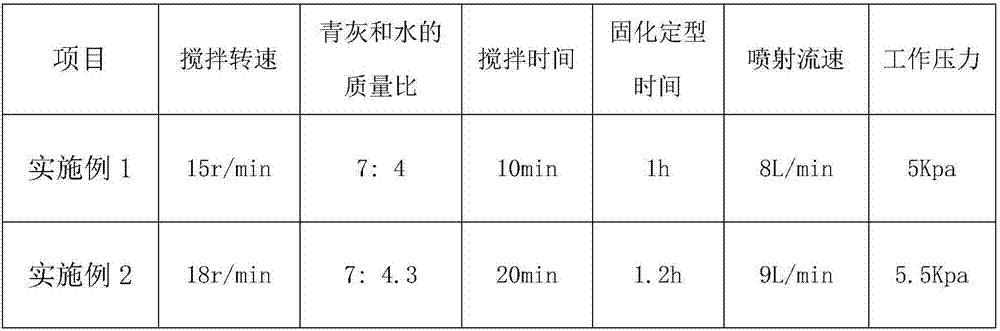

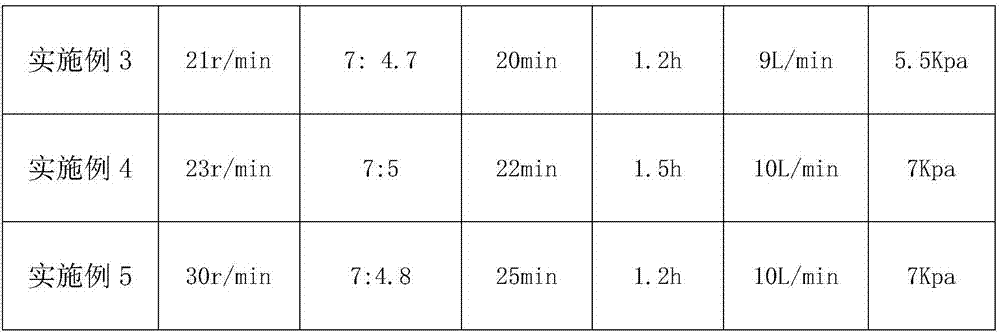

Embodiment 1

[0050] Add blue ash and water to the first concrete mixer according to 7:4, and at a stirring speed of 15r / min, through the dual stirring action of the stirring rod and the stirring wheel in the first concrete mixer, stir for 10min under normal temperature conditions, and then The mixed material is transported to the pneumatic spraying machine, and the material is sprayed irregularly on the surface of the mold at a flow rate of 8L / min through the two pneumatic spraying heads of the pneumatic spraying machine, and then solidified and shaped at room temperature. The setting time is 1h, and the working pressure of the pneumatic spraying machine is 5Kpa;

[0051] Mix ore sand, cement and pigment according to the mass ratio of 150:90:7, firstly mix the ore sand and cement, then add black stone powder, blue stone powder and green stone powder to the mixture of ore sand and cement successively according to 3:2:5 After the cement additive is added and mixed evenly, the weight of the c...

Embodiment 2

[0055] Add blue ash and water into the first concrete mixer according to 7:4.3, under the mixing speed of 18r / min, through the dual stirring action of the stirring rod and the stirring wheel in the first concrete mixer, stir under normal temperature for 20min, then put The mixed material is transported to the pneumatic spraying machine, and the material is sprayed irregularly on the surface of the mold at a flow rate of 9L / min through the two pneumatic spraying heads of the pneumatic spraying machine, and then solidified and shaped at room temperature. The setting time is 1.2h, and the working pressure of the pneumatic spraying machine is 5.5Kpa;

[0056] Mix ore sand, cement and pigment according to the mass ratio of 150:90:7, firstly mix the ore sand and cement, then add black stone powder, blue stone powder and green stone powder to the mixture of ore sand and cement successively according to 3:3:5 After the cement additive is added and mixed evenly, the weight of the cemen...

Embodiment 3

[0060] Add blue ash and water into the first concrete mixer according to 7:4.7, under the mixing speed of 21r / min, through the dual stirring action of the stirring rod and the stirring wheel in the first concrete mixer, stir under normal temperature for 20min, then put The mixed material is transported to the pneumatic spraying machine, and the material is sprayed irregularly on the surface of the mold at a flow rate of 9L / min through the two pneumatic spraying heads of the pneumatic spraying machine, and then solidified and shaped at room temperature. The setting time is 1.2h, and the working pressure of the pneumatic spraying machine is 5.5Kpa;

[0061] Mix ore sand, cement and pigment according to the mass ratio of 150:90:7, firstly mix the ore sand and cement, then add black stone powder, blue stone powder and green stone powder to the mixture of ore sand and cement successively according to 3:2:7 After the cement additive is added and mixed evenly, the weight of the cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com