Solid content 100% unsaturated polyester resin and low voc clean odor pe varnish

A polyester resin, unsaturated technology, applied in the field of low-VOC net-odor PE varnish, can solve the problems of high VOC content, unpleasant construction odor, etc., and achieve the effect of improving air-drying performance, good viscosity and air-drying property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

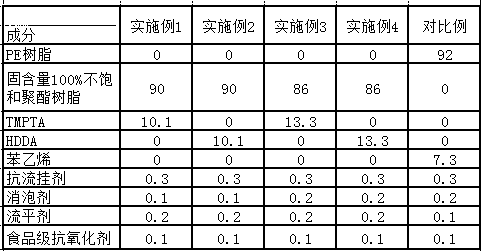

Examples

Embodiment 1

[0036] An unsaturated polyester resin with a solid content of 100%, prepared from three groups of raw materials A, B, and C. The raw materials of group A include by weight: 5 parts of phthalic anhydride, 15 parts of fumaric acid, trihydroxy 10 parts of methyl propane, 10 parts of glycidyl tertiary carbonic acid ester, 15 parts of propylene glycol, 10 parts of neopentyl glycol, 0.01 part of hydroquinone, 0.5 part of triphenyl phosphite, 0.05 part of monobutyltin oxide; group B The raw materials in parts by weight include: 10 parts of trimethylolpropane diallyl ether and 0.01 part of hydroquinone; the raw materials in group C include 0.03 parts of hydroquinone in parts by weight.

[0037] The preparation method of described solid content 100% unsaturated polyester resin, comprises the following steps:

[0038] S1. Put component A into the reaction kettle, feed nitrogen gas, start stirring to raise the temperature, raise the temperature to 160~170°C and keep it warm for 1~2 hours...

Embodiment 2

[0047] An unsaturated polyester resin with a solid content of 100%, prepared from three groups of raw materials A, B and C. The raw materials of group A include by weight: 15 parts of phthalic anhydride, 20 parts of fumaric acid, trihydroxy 5 parts of methyl propane, 20 parts of glycidyl tert-carbonate, 10 parts of propylene glycol, 15 parts of neopentyl glycol, 0.05 parts of phenothiazine, 0.2 parts of hypophosphorous acid, 0.01 part of dibutyltin dilaurate; Group B raw materials by weight The parts include: 5 parts of trimethylolpropane diallyl ether, 0.03 parts of phenothiazine; the raw materials of group C include: 0.05 parts of hydroquinone in parts by weight.

[0048]The preparation method of described solid content 100% unsaturated polyester resin, comprises the following steps:

[0049] S1. Put component A into the reaction kettle, feed nitrogen gas, start stirring to raise the temperature, raise the temperature to 160~170°C and keep it warm for 1~2 hours;

[0050] S2...

Embodiment 3

[0058] An unsaturated polyester resin with a solid content of 100%, prepared from three groups of raw materials A, B, and C. The raw materials of group A include by weight: 10 parts of phthalic anhydride, 25 parts of fumaric acid, trihydroxy 7 parts of methyl propane, 15 parts of glycidyl tert-carbonate, 5 parts of propylene glycol, 20 parts of neopentyl glycol, 0.04 parts of hydroquinone, tetrakis[β-(3,5-di-tert-butyl-4-hydroxybenzene base) propionic acid] 0.1 part of pentaerythritol ester, 0.02 part of monobutyl tin oxide; the raw materials of group B include: 15 parts of trimethylolpropane diallyl ether, 0.02 part of hydroquinone; the raw materials of group C Included in parts by weight: 0.02 part of phenothiazine.

[0059] The preparation method of described solid content 100% unsaturated polyester resin, comprises the following steps:

[0060] S1. Put component A into the reaction kettle, feed nitrogen gas, start stirring to raise the temperature, raise the temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com