A hfte5-δ crystal with huge magnetoresistance and its growth method

A growth method and magnetoresistance technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of no measured linear conductance, no superlattice structure diffraction spots, small resistivity anisotropy, etc. , to achieve significant application value, optimize the crystal growth process, and optimize the effect of crystal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, transport agent is I 2 HfTe 5 Powder as raw material to grow HfTe 5-δ the crystal

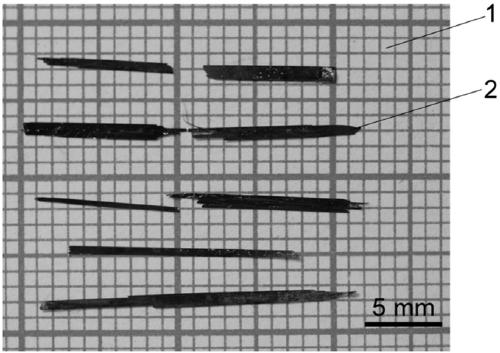

[0035] Weigh 0.02mol of Hf powder (3.5698g) and 0.1mol of Te powder (12.7600g), mix them evenly and put them into a quartz tube that has been cleaned and dried beforehand. The quartz tube was sealed with a flame, and the high-temperature solid-state sintering reaction was carried out at 500 °C for 5 days to prepare HfTe 5 Powder, as a growth material. Then weigh 0.002mol (1.6330g) of HfTe 5 Powder with 100 mg of Delivery Agent I 2 , and respectively add a series of excess Te powder (0.5%, 0.0064g; 1%, 0.0127g; 3%, 0.0383g), grind and mix the three and put them into the prepared quartz tube (length 10cm, diameter 2cm ). After the quartz tube is sealed, it is placed in a tube furnace with two temperature zones or multiple temperature zones, and the growth temperature program is set at 400°C (growth end) to 550°C (raw material end). After a 10-day growth cycle, the seri...

Embodiment 2

[0037] Embodiment 2, transport agent is I 2 Growth of HfTe with stoichiometric ratio of Hf powder and Te powder as raw materials 5-δ the crystal

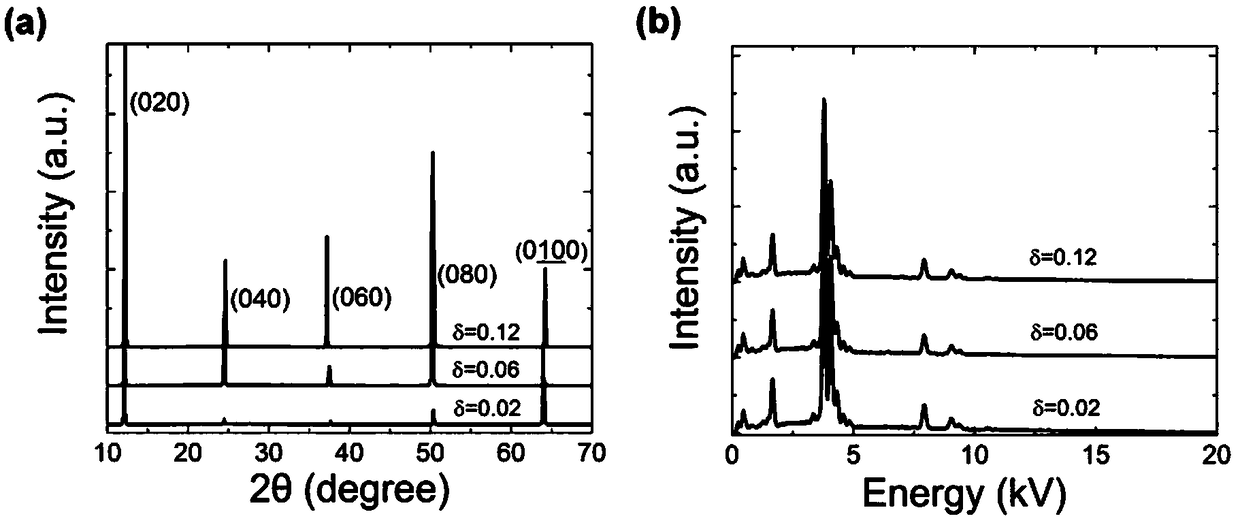

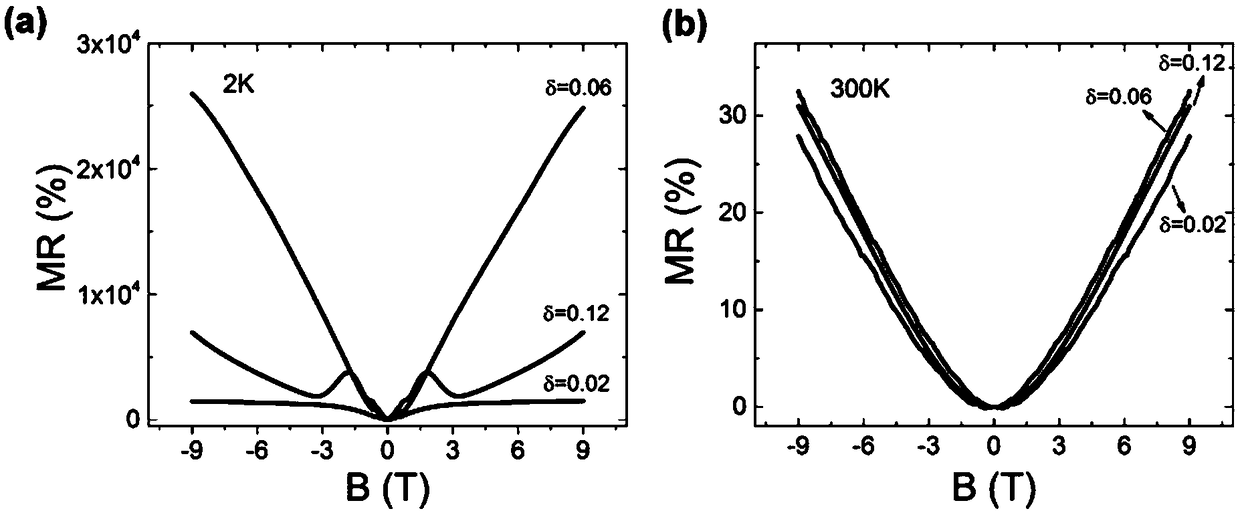

[0038] Directly weigh 0.002mol of Hf powder (0.3570g) and 0.01mol of Te powder (1.2760g) as growth materials. Then weigh 100mg of I 2 As a transport agent, add a series of excess Te powder (0.5%, 0.0064g; 1%, 0.0127g; 3%, 0.0383g), grind and mix the three into the prepared quartz tube (length 10cm, diameter 2cm). After the quartz tube is sealed, place it in a tube furnace with two temperature zones or multiple temperature zones. Set the growth temperature program to 400°C (growth end) ~ 550°C (raw material end). After a 10-day growth cycle, the series can be obtained by natural cooling. Centimeter-scale HfTe with giant magnetoresistance 5-δ large single crystals, such as figure 1 shown. EDS test results show that three kinds of HfTe 5-δ The crystal values are 0.03, 0.07, 0.13, respectively. The magnetoresistance effect te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com