Solar supercritical carbon dioxide cycle power generation and steam electrolysis hydrogen production coupled system

A technology of carbon dioxide and water vapor, applied in solar thermal power generation, solar heating systems, solar thermal energy, etc., can solve the problems of primary energy consumption, complex process, low efficiency, etc., achieve hydrogen production cost reduction, broaden application fields, and high thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

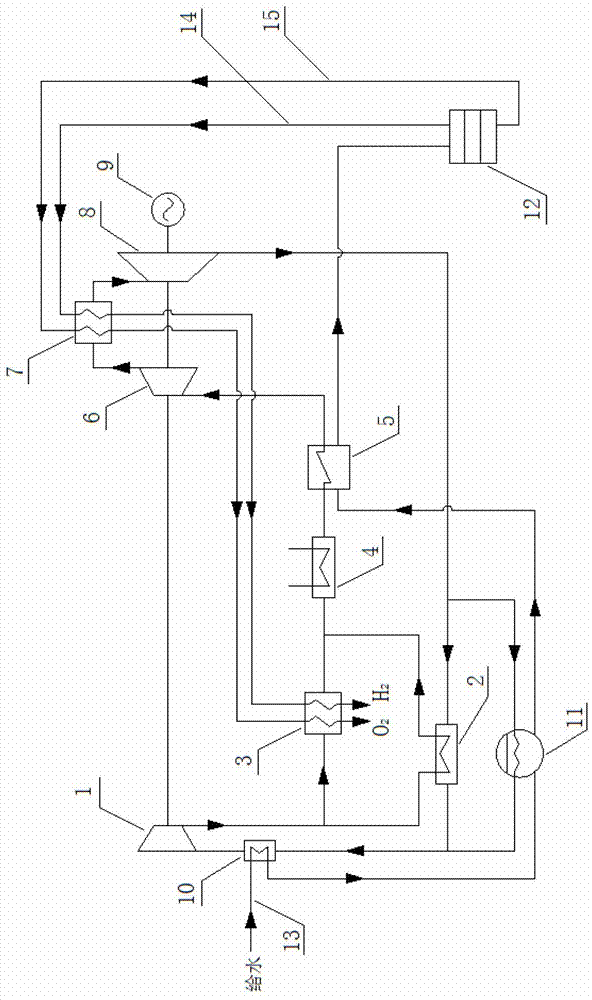

[0017] Such as figure 1 As shown, the present invention is a solar supercritical carbon dioxide cycle power generation coupled with water vapor electrolysis hydrogen production system, including compressor 1, regenerator 2, preheater 3, high concentration solar receiver 4, water vapor superheater 5, high pressure Carbon dioxide gas turbine 6, reheater 7, low pressure carbon dioxide gas turbine 8, generator 9, cooler 10, steam generator 11, solid oxide electrolyzer 12, water supply pipeline 13, hydrogen pipeline 14, oxygen pipeline 15.

[0018] The outlet of the compressor 1 is divided into two paths by pipelines: one is connected to the tube side inlet of the regenerator 2, and the other is connected to the shell side inlet of the preheater 3; the tube side of the regenerator 2 The outlet and the shell-side outlet of the preheater 3 are merged into one way to connect with the working fluid inlet of the high-concentration solar receiver 4 through a pipeline; the working fluid outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com