Low CTE glass with high UV transmittance and light fastness

A technology of ultraviolet light and transmittance, applied in the field of low CTE glass, can solve problems such as unsuitability, contamination of silicon substrates, non-silicon substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The objects, features and advantages of the present invention will be shown in more detail by the examples and embodiments described hereinafter with reference to the accompanying drawings.

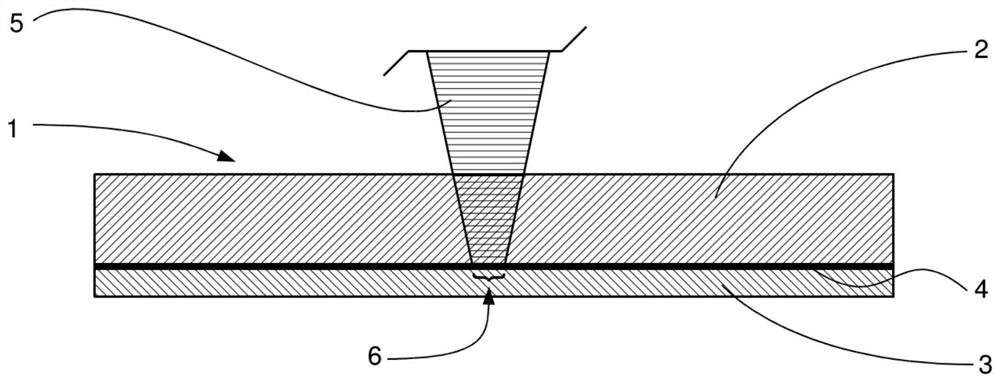

[0051] figure 1 A bonded product comprising a glass carrier wafer 2 during a debonding process by laser release is schematically shown. The bonded article 1 comprises a glass carrier wafer 2 made of glass according to the invention and a silicon substrate 3 bonded together by an adhesive layer 4 which can be deactivated by exposure to electromagnetic radiation. In this example, the adhesive layer 4 can be deactivated by UV radiation at a wavelength of 248 nm, so that the adhesion force is reduced or eliminated, so that the silicon substrate 3 can be debonded. The debonding (laser release) is achieved by irradiating the adhesive layer 4 with a laser 5 through the glass carrier wafer 2 . In a typical process, the wafer is mounted on a computer numerically controlled (CNC) controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com