Side-channel blower for an internal combustion engine, comprising a wide interrupting gap

A side channel, internal combustion engine technology, applied in parts of pumping devices for elastic fluids, crankcase ventilation, machines/engines, etc., can solve problems such as rotor jamming, condensate freezing, etc., to reduce noise emission and reduce sensitivity Degree, improve the effect of conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

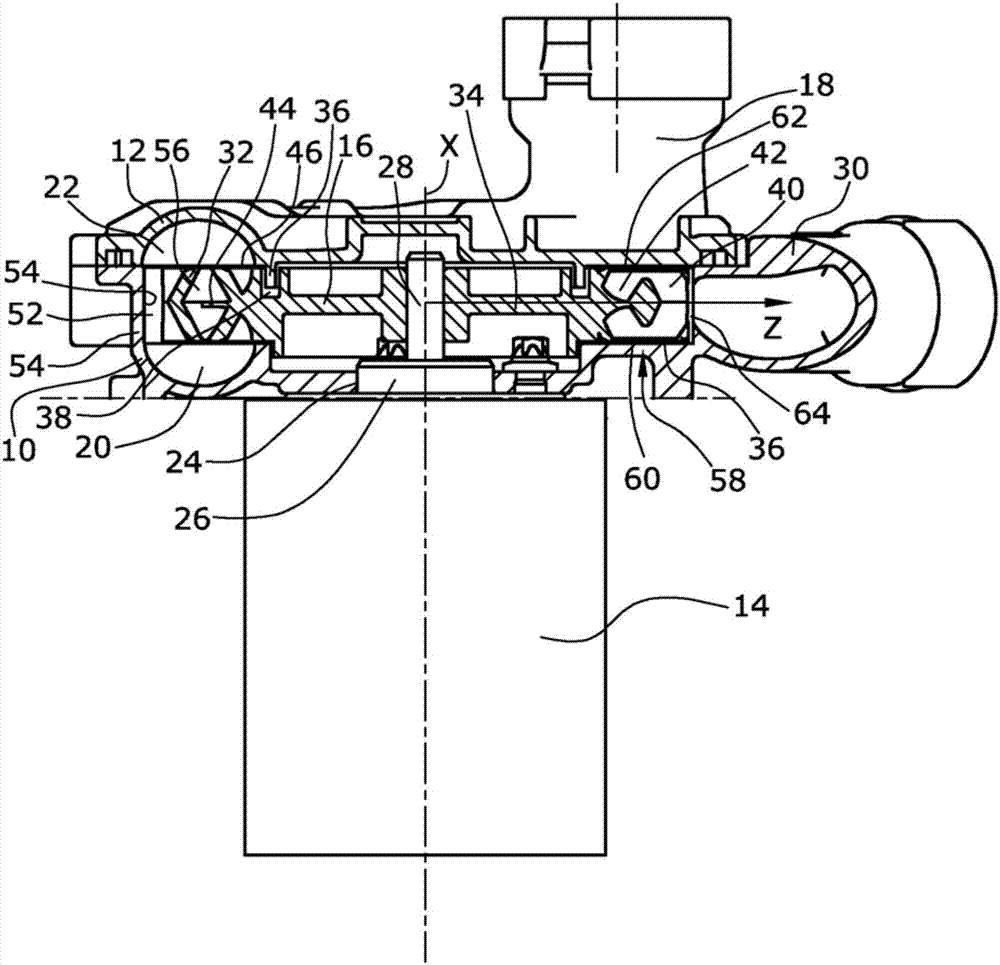

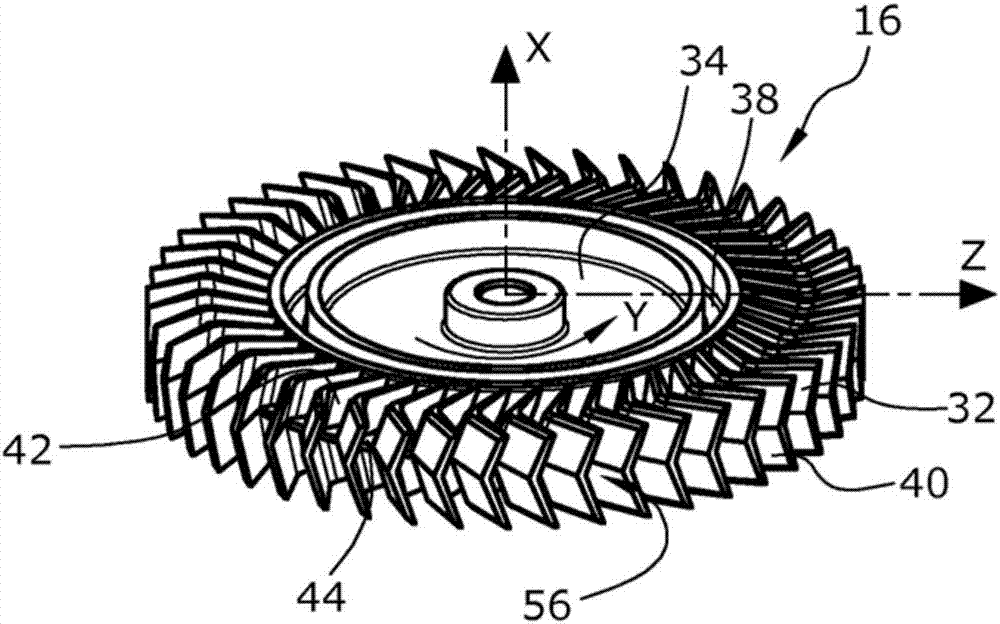

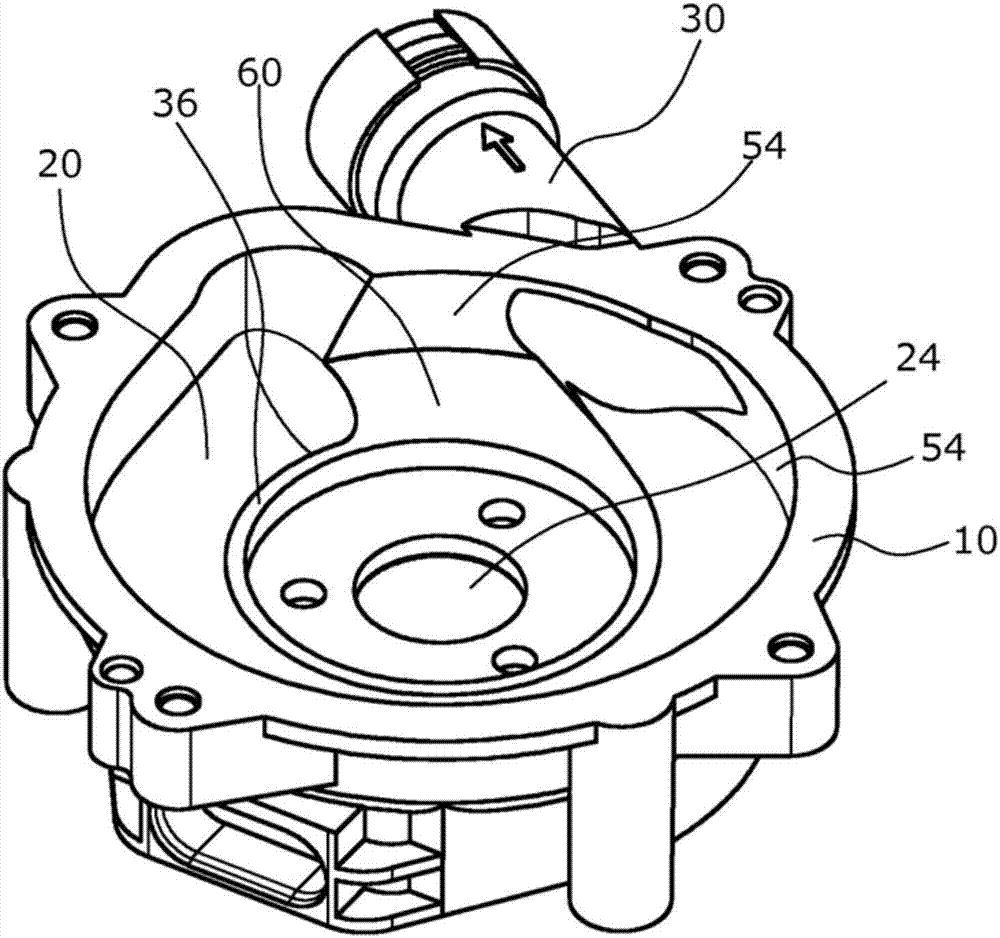

[0023] figure 1 The side-channel blower shown in has a two-part air flow housing consisting of a support housing 10 and a housing cover 12 fastened to the support housing 10, for example with screws. A rotor 16 rotatable by means of a drive 14 is mounted in the bearing housing 10 . The conveyed compressible medium reaches the inside of the side channel blower through the axial inlet 18 designed in the housing cover 12 .

[0024] The medium from the inlet 18 then flows into two substantially annularly extending conveying channels 20, 22, wherein the first conveying channel 20 is designed in the support housing 10, in which the drive shaft 28 of the drive 14 is also mounted in its central hole 24. Bearings 26 , rotor 16 are fixed on drive shaft 28 , and second feed channel 22 is formed in housing cover 12 . Exhaust gas takes place via a tangential outlet 30 formed in the support housing 10 .

[0025] The rotor 16 is mounted between the housing cover 12 and the supporting hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com