Method for processing green tea with flowery fragrance from worm-eaten fresh tea leaves and product thereof

A technology of tea fresh leaves and flower fragrance, applied in the field of methods and its products, can solve the problems of waste of tea leaves resources, pesticide residues, etc., and achieve the effects of solving tea waste, improving quality, and reducing pesticide spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The fresh leaf raw materials used are: the picked variety is golden tea, and the tenderness is 35kg of fresh tea leaves bitten by weevils, mainly 1 bud and 1 leaf.

[0046] The specific implementation is as follows:

[0047] (1) Harvest the raw materials of fresh leaves for making flower-flavored mellow green tea and spread them evenly on bamboo trays. The thickness of the spread leaves is such that the leaves do not cover the leaves. Dry the green leaves in low light for 1 hour, and then move the fresh leaves to a cool place and spread them for 15 minutes. , so repeated 2-3 times, until the fresh leaves emit a floral fragrance, and the moisture content of the fresh leaves is about 72%.

[0048](2) Put the sun-dried green leaves treated in step 1 into a shade net with a length of 3.5m and a width of 1.5m, and sew the shade net with a rope. Two people each grab a corner of the bag and shake the shade bag slowly , let the spread leaves do a circular motion in the shade b...

Embodiment 2

[0056] The raw materials of fresh leaves used are: 30kg of fresh tea leaves bitten by weevils whose tenderness is mainly 1 bud and 2 leaves, picked from Fuding Dabai.

[0057] The specific implementation is as follows:

[0058] (1) Harvest the raw materials of fresh leaves for making flower-flavored mellow green tea and spread them evenly on bamboo trays. The thickness of the spread leaves is such that the leaves do not cover the leaves. Dry the green leaves in low light for 1 hour, and then move the fresh leaves to a cool place and spread them for 15 minutes. , so repeated 2-3 times, until the fresh leaves emit a floral fragrance, and the moisture content of the fresh leaves is about 71%.

[0059] (2) Put the sun-dried green leaves treated in step 1 into a shade net with a length of 3.5m and a width of 1.5m, and sew the shade net with a rope. Two people each grab a corner of the bag and shake the shade bag slowly , let the spread leaves do circular motions in the shade bag, ...

Embodiment 3

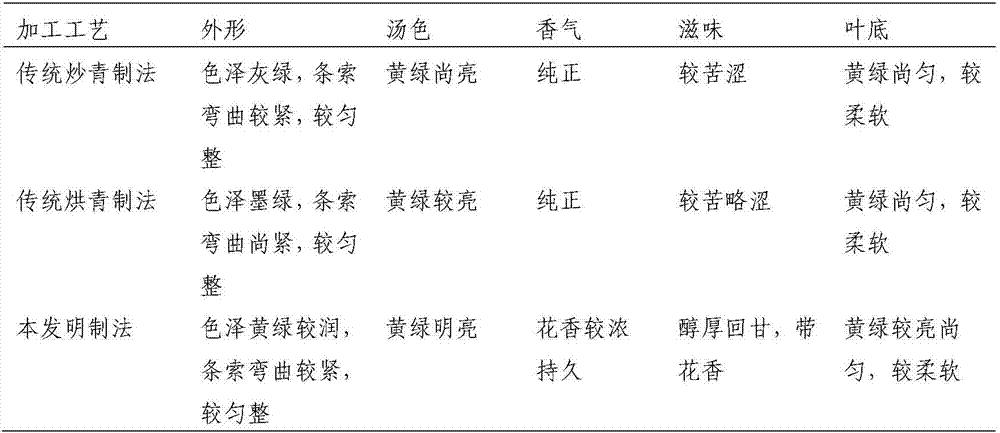

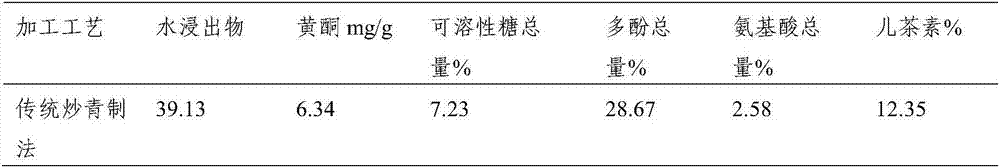

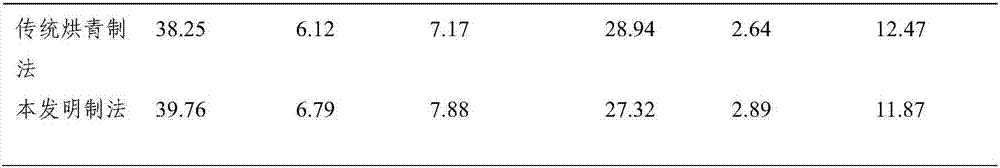

[0067] Comparing the green tea processed by the method of the present invention and the traditional method, the results of sensory evaluation and the results of the contained components of the prepared tea products are shown in Table 1 and Table 2. As can be seen from Table 1, the green tea prepared by the present invention has a mellow mouthfeel and floral aroma, which is significantly improved compared with traditional green tea flavor quality, indicating that the processed product of the present invention is better than traditional green tea in aroma and mouthfeel. Table 2 shows that compared with the tea prepared by the traditional method, soluble sugars, amino acids, and other substances that are beneficial to the quality of tea soup have all increased, and the content of tea polyphenols and catechins with a bitter taste has decreased, and the ratio of phenol to ammonia is more suitable. , so the taste is mellow and sweet.

[0068] Table 1:

[0069]

[0070] Table 2: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com