Organosilicon composition and preparation and application thereof

A technology of organosilicon and composition, applied in the field of fine chemical preparations, can solve the problems of not being able to take into account the defoaming performance and the stability of compatible products at the same time, and achieve the effect of improving stability and improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

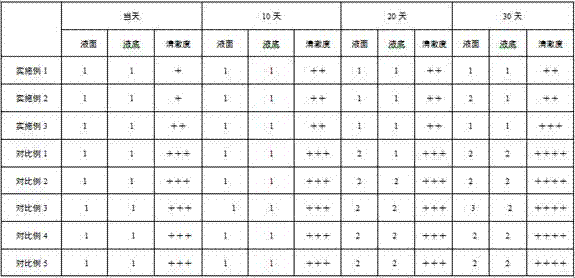

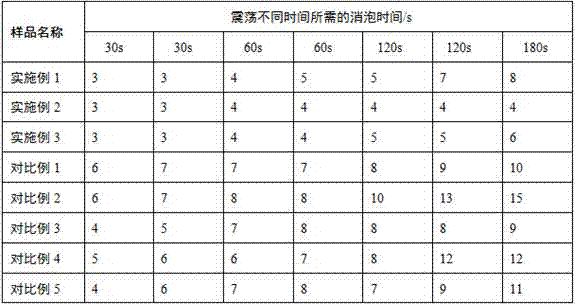

Examples

Embodiment 1

[0044] Add 50 parts into the reaction vessel, the viscosity is 50mPa.s (unless otherwise specified, the viscosity mentioned below is the kinematic viscosity value at 25°C), and the structural formula is (Me) 3 SiO (MeViSiO) 2 [(Me) 2 SiO] 50 Si(Me) 3 (It is mentioned in the text that Vi is the abbreviation of vinyl functional group) vinyl polyorganosiloxane, 25 parts of hydrogen-containing silicone resin with a hydrogen content of 0.1%, mix well and heat up to 70°C, add 0.0005 Parts (calculated as platinum) chloroplatinic acid isopropanol solution, continue to heat up to 100 ° C for 1 h; then add 400 parts dropwise to the container 3 SiO(MeHSiO) 20 [(Me) 2 SiO] 350 Si(Me) 3 Hydrogen-containing polyorganosiloxane, the dropwise addition time is controlled to be 2h, and the reaction is continued at 100°C for 1h after the dropwise addition; 15 parts of hydrophobic precipitation silica Sipernat® D10 (sold by Degussa Gmbh), 10 parts of formazan Based on MQ silicone resin (M:...

Embodiment 2

[0046] In the reaction vessel, add 395 parts of viscosities of 50mPa.s, structural formula Vi(Me) 2 SiO (MeViSiO) 101 [(Me) 2 SiO] 50 Si(Me) 2 Vinyl polyorganosiloxane of Vi, 5 parts of hydrogen-containing silicone resin with a hydrogen content of 0.2%, fully mixed and heated to 70°C, adding 0.005 parts (calculated as platinum) of isopropanol containing chloroplatinic acid Solution, continue to heat the reaction at 70°C for 1h; then add 90 parts dropwise to the container 2 SiO(MeHSiO) 11 [(Me) 2 SiO] 55 Si(Me) 2 H hydrogen-containing polyorganosiloxane, control the dropping time for 2h, continue to react at 70°C for 1h after the dropping is completed; add 5 parts of hydrophobic precipitation silica Sipernat® D10 (sold by Degussa Gmbh), 5 parts Methyl MQ silicone resin (M:Q ratio 1:1), stirred at 150°C for 2h, and obtained silicone active material A2 after cooling down to room temperature

Embodiment 3

[0048] Add 200 parts of the viscosity is 50mPa.s, structural formula is (Me) in the reaction vessel 3 SiO (MeViSiO) 2 [(Me) 2 SiO] 50 Si(Me) 3 Vinyl polyorganosiloxane, 10 parts of hydrogen-containing silicone resin with a hydrogen content of 0.2%, fully mixed and heated to 70 ° C, adding 0.05 parts (calculated as platinum) isopropanol solution of chloroplatinic acid , continue to heat up to 100°C for 1 hour; then dropwise add 140 parts of 3 SiO(MeHSiO) 2 [(Me) 2 SiO] 55 Si(Me) 3 Hydrogen-containing polyorganosiloxane, the dropwise addition time is controlled to be 2h, and the reaction is continued at 150°C for 1h after the dropwise addition; 75 parts of hydrophobic precipitation silica Sipernat® D17 (sold by Degussa Gmbh), 75 parts of formazan Based on MQ silicone resin (M:Q ratio 0.9:1), stirred at 150°C for 2h, and after cooling down to room temperature, silicone active material A3 was obtained

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com