Wall structure with no cold bridge

A wall structure and wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of reduced thermal insulation performance, increased sound insulation effect, increased construction difficulty, etc., to achieve anti-corrosion protection, safe and reliable installation process, The effect of preventing the entry of water and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

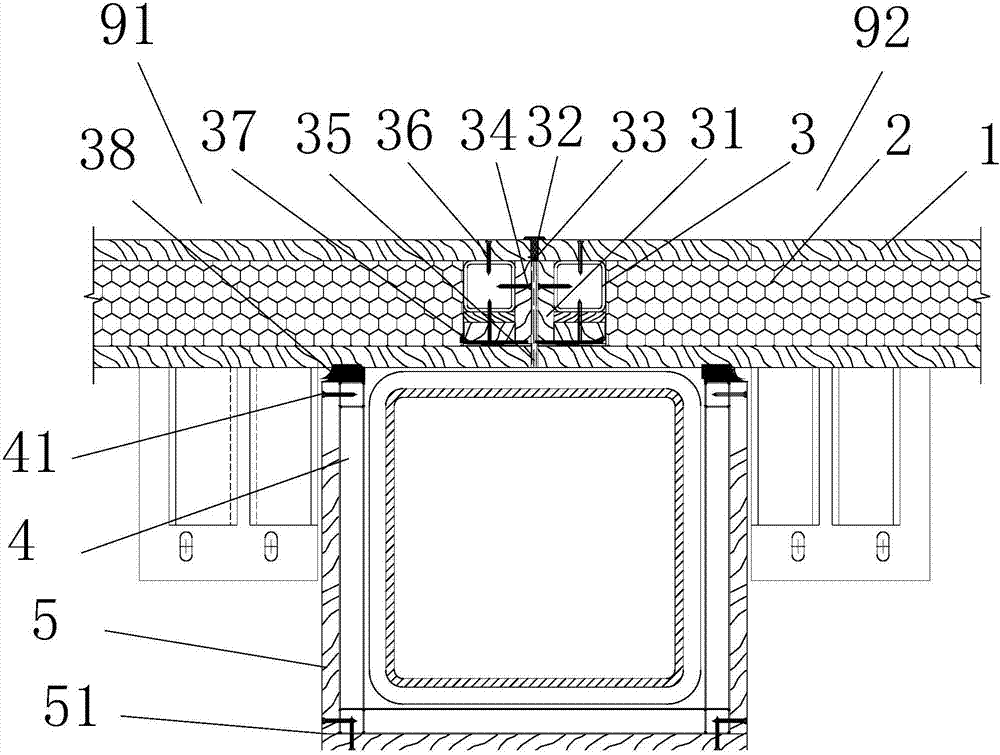

[0024] see figure 1 As shown, it is a schematic diagram of Embodiment 1 of the wall structure without cold bridge of the present invention. In this embodiment, the first wall module 91 and the second wall module 92 include panels 1 on both sides and panels 1 Inner insulation layer 2.

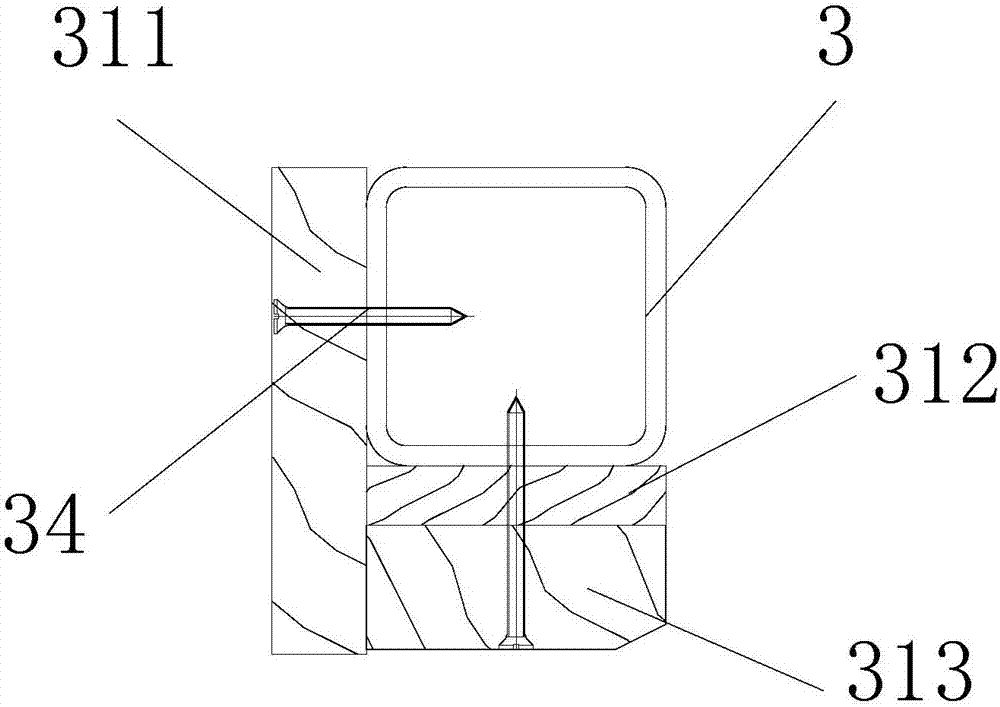

[0025] Set the outer wall keel steel pipe 3 at the end of each wall formwork, the upper side of the outer wall keel steel pipe 3 is in contact with the panel 1 on the upper layer of the wall module; please combine figure 2 As shown, a structural plate 31 is provided on one side and the lower part of the outer wall keel steel pipe 3 . When two adjacent wall formworks are connected, in this embodiment, when the first wall module 91 and the second wall module 92 are connected, between the outer wall keel steel pipes 3 at the ends of the two wall modules and The structural plate 31 is arranged between the outer wall keel steel pipe 3 and the lower panel 1 of the wall module.

[0026] Please comb...

Embodiment 2

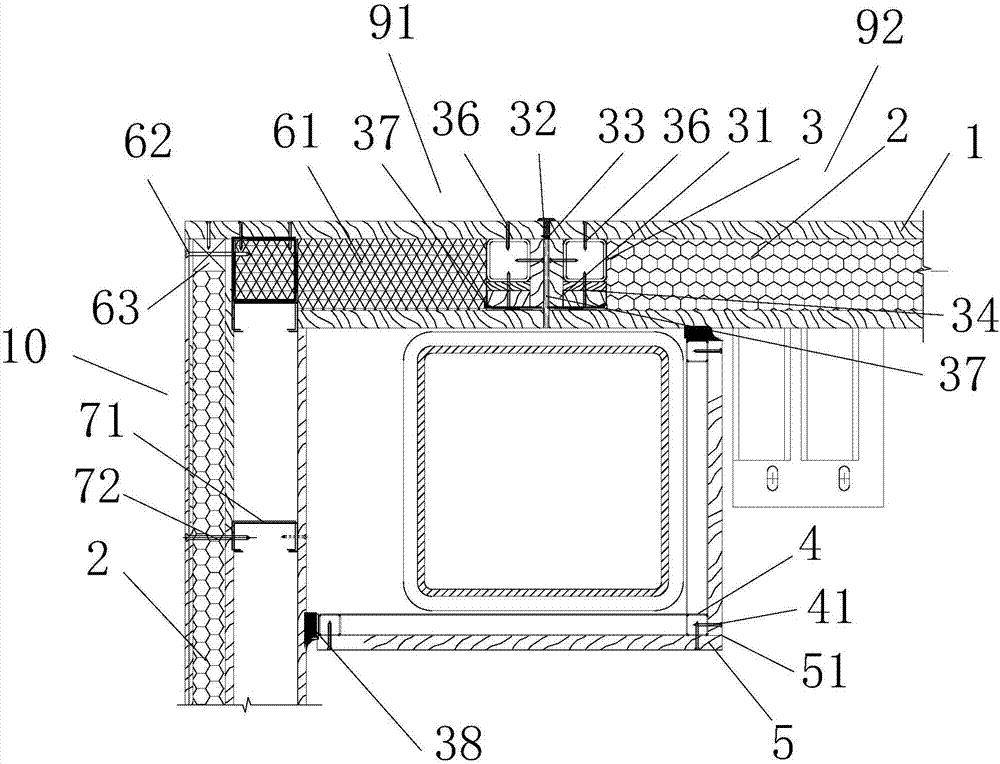

[0037] The difference between this embodiment and the above-mentioned embodiments is that a partition wall 10 is provided in this embodiment, and the thermal insulation layer of the outer wall at the connection between the partition wall 10 and the outer wall is filled with rock wool board 61 with a small thermal conductivity.

[0038] A spacer 63 is also arranged at the corner of the partition wall 10 and the outer wall. The spacer 63 is arranged at the end of the insulation layer of the partition wall 10 . The spacer 63 and the rock wool board 61 are connected by the fourth screw 62 .

[0039] The partition wall 10 is also provided with an inner wall keel steel pipe 71 , and the insulation layer and the inner wall keel steel pipe 71 are connected by fifth screws 72 .

[0040] In this embodiment, an elastic fireproof sealant 38 is applied to the connection between the fireproof board 5 and the outer wall and the partition wall.

[0041] The invention effectively prevents the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com