Non-doped high-efficiency organic photovoltaic cells

An organic photovoltaic cell, high-efficiency technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of increasing heterojunction interface, complex preparation process, and complex battery structure, so as to improve energy conversion efficiency and battery structure. The effect of increasing the number of simple, dissociated interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

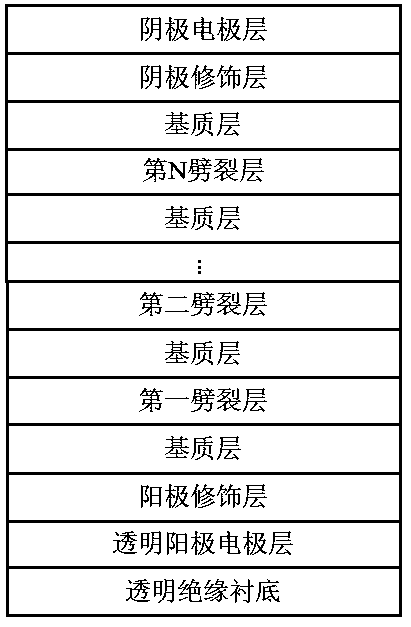

[0029]Non-doped high-efficiency organic photovoltaic cells, the device structure is: transparent insulating substrate Glass 1.2 mm / transparent anode electrode layer ITO 200 nm / anode modification layer MoO3 5 nm / C70 15 nm / first split layer TAPC 5 nm / C70 15nm / second split layer TAPC 5 nm / C70 15 nm / third split layer TAPC 5 nm / C70 15 nm / cathode modification layer Bphen 5 nm / cathode electrode Al 100 nm, wherein the matrix layer is 60 nm of C70, There are three splitting layers in the battery, that is, N=3, which can form six organic heterojunction interfaces for exciton dissociation. The distance between the first splitting layer and the MoO3 anode modification layer is greater than 5 nm, and the third splitting layer The distance from the Bphen cathode modification layer is greater than 5 nm, the distance between the first split layer and the second split layer is greater than 5 nm, and the distance between the second split layer and the third split layer is greater than 5 n...

Embodiment 2

[0031] Non-doped high-efficiency organic photovoltaic cells, the device structure is: transparent insulating substrate Glass 1.2 mm / transparent anode electrode layer ITO 200 nm / anode modification layer MoO3 5 nm / C60 10 nm / first splitting layer NPB 2 nm / C60 10 nm / second splitting layer NPB 2 nm / C60 10 nm / third splitting layer NPB 2 nm / C60 10 nm / fourth splitting layer NPB 2nm / C60 10 nm / cathode modification layer BCP 10 nm / cathode electrode Ag 80 nm, in which the matrix layer is 40 nm C60, there are four splitting layers in the battery, that is, N=4, which can form 8 organic heterojunction interfaces for exciton dissociation.

Embodiment 3

[0033] N=1, Glass 1.2 mm / transparent anode electrode layer ITO 200 nm / anode modification layer MoO3 5 nm / C70 25nm / first splitting layer TPD 5 nm / C70 25 nm / cathode modification layer BCP 10 nm / cathode electrode Ag 80 nm, where the matrix layer is 50 nm C70, and the splitting layer in the cell is 5 nm TPD, which can form two organic heterojunction interfaces for exciton dissociation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com