Process for preparing multilayer heterogeneous bionic joint cartilage material

A bionic joint and preparation process technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of aseptic loosening and artificial joint wear, and achieve the effects of sufficient biological activity, not easy to wear and loosen, and good interface lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

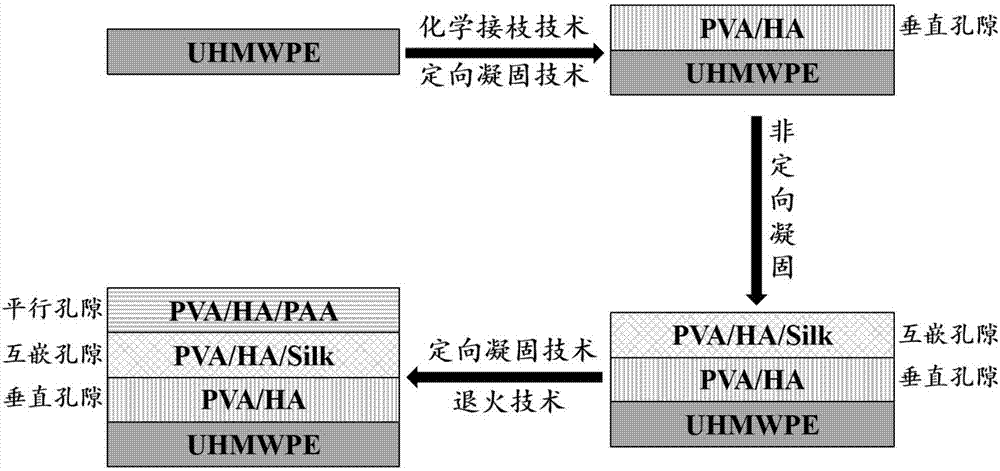

[0033] Such as figure 1 As shown, a multilayer heterogeneous biomimetic articular cartilage material preparation process includes the following steps:

[0034] 1) Soak the polyethylene block (molecular weight: 3 million) in the dichromic acid oxidation solution, place it in a 75°C water bath for 10 minutes, and then place it in a 50°C nitric acid solution for 10 minutes to remove the small molecules formed on the surface after oxidation Material, take out and clean with a large amount of deionized water; Described dichromic acid oxidation solution is to be configured by mass percentage 1:4 by potassium dichromate and concentrated sulfuric acid;

[0035] 2) Weigh 25% of polyvinyl alcohol, 3% of nano-hydroxyapatite and 72% of deionized water in a container, swell at room temperature for 24 hours, and then place the container in a constant temperature water bath at 95°C to prepare Get out the PVA / HA mixed solution; take 7% polyvinyl alcohol, 1.5% concentrated sulfuric acid and 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com