A hot stamping forming method for zinc-based coated steel sheet or steel strip

A technology of hot stamping forming and hot stamping, which is applied in the field of forming structural parts, hot stamping steel plates and steel strips, to achieve the effects of saving energy consumption, reducing heating temperature, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

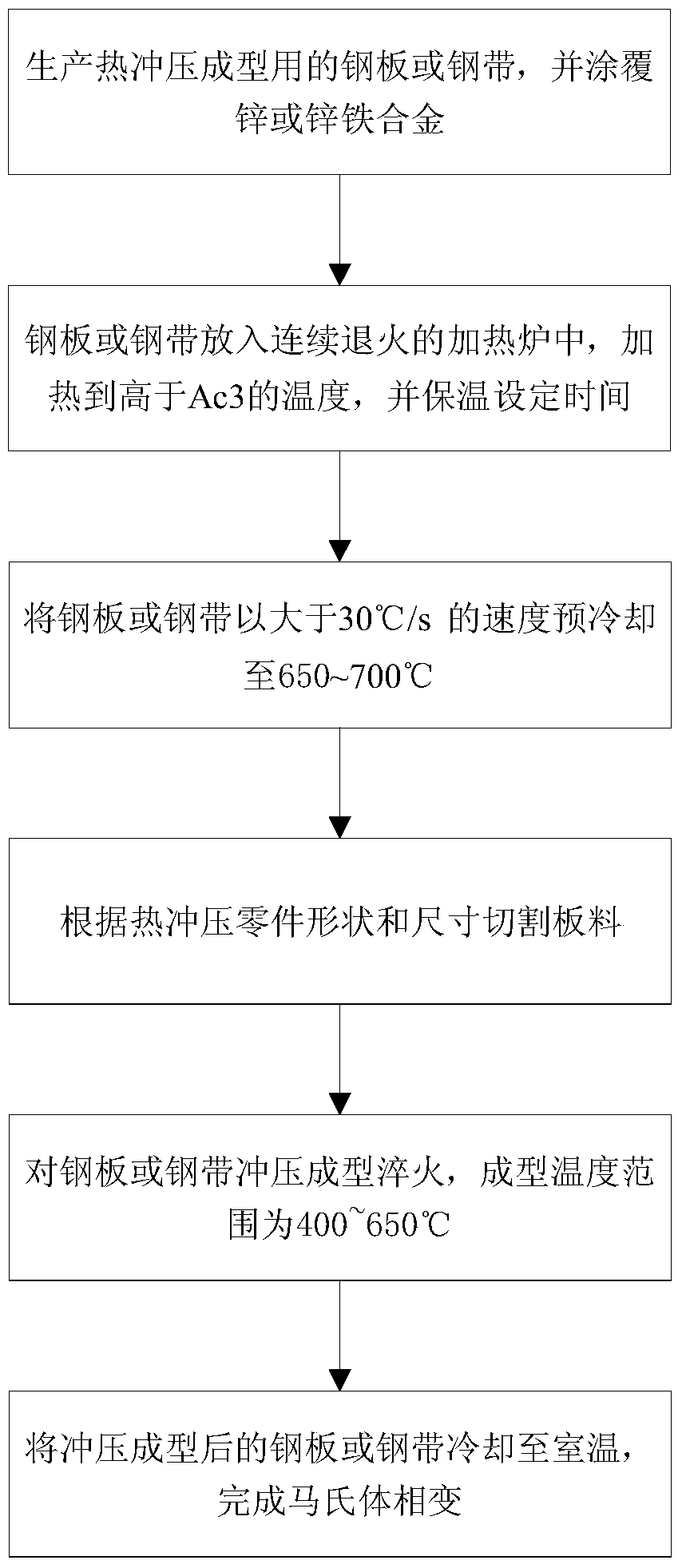

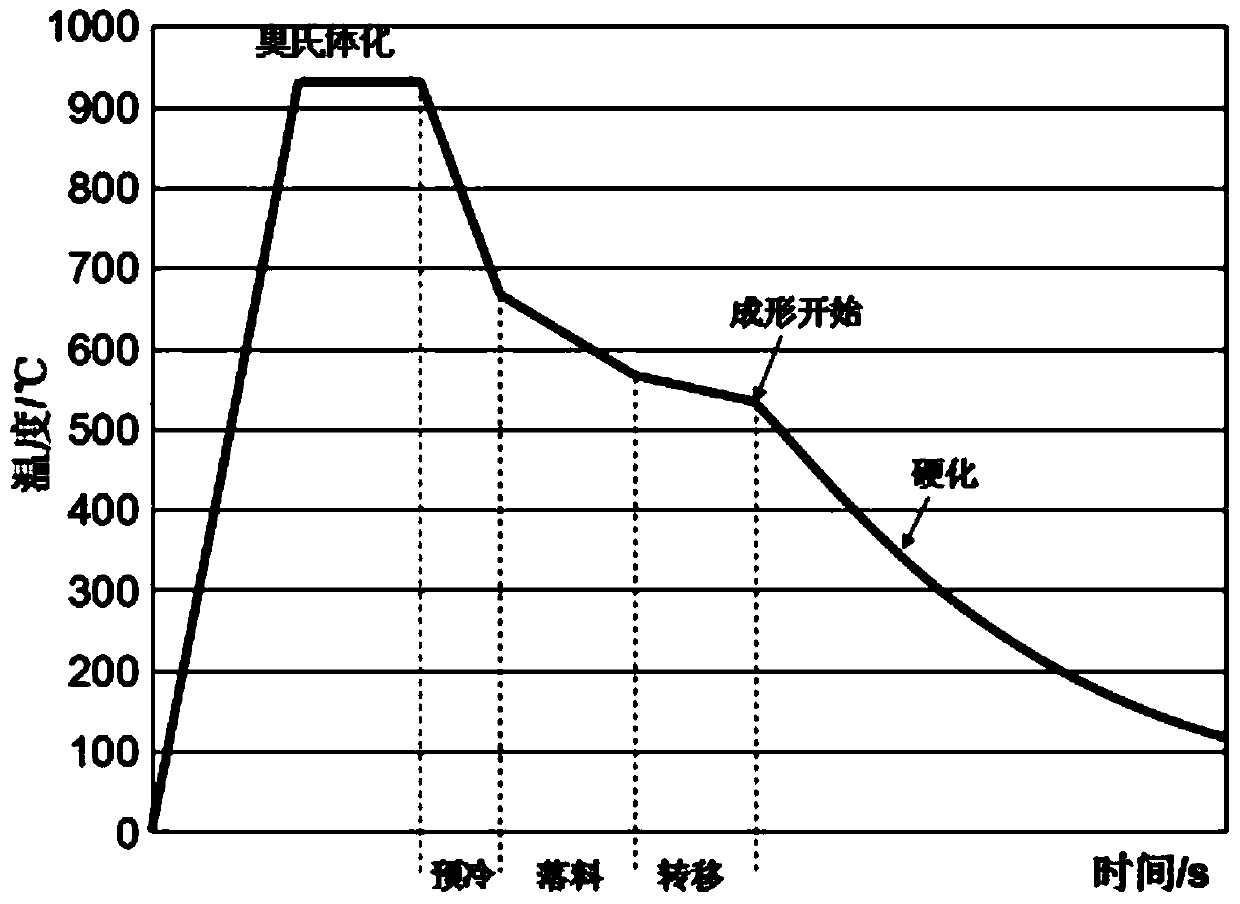

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Since the zinc-based hot stamping process in the prior art is easy to cause cracks in the substrate, in order to overcome the defects in the prior art, the present invention provides a method that can simultaneously improve the hot stamping efficiency and avoid the hot stamping of zinc-based hot stamping steel. Hot stamping forming process for substrate cracks. After the process of the invention is used for hot stamping, the tensile strength of the steel plate or steel strip is greater than 1500MPa, and at the same time, the substrate cracks caused by local stress and LME are avoided.

[0035] The present invention firstly provides a steel for hot stamping, its composition is mainly (all data are mass %): C: 0.1%-0.5%, Si: 0.1%-0.5%, Mn: 0.5%-3.0%, B : 0%~0.010%, Ti: 0%~0.20%, Nb: 0%~0.20%, V: 0%~1.0%,, W: 0%~1.0%, Cr: 0%~1.0%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com