A special oil for viscous granular emulsified explosives

An emulsion explosive and special oil technology, which is applied in explosives, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of unstable nature and supply of substitute materials, unfriendly environment, poor safety, etc., and avoid production costs. Improved, environmentally friendly, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

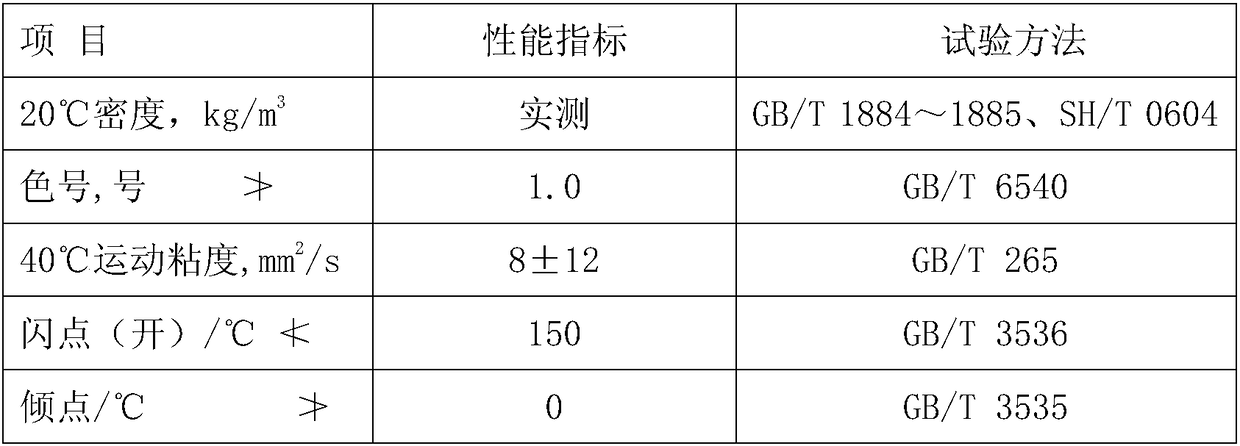

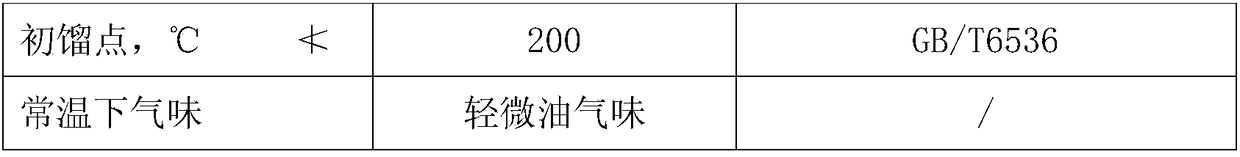

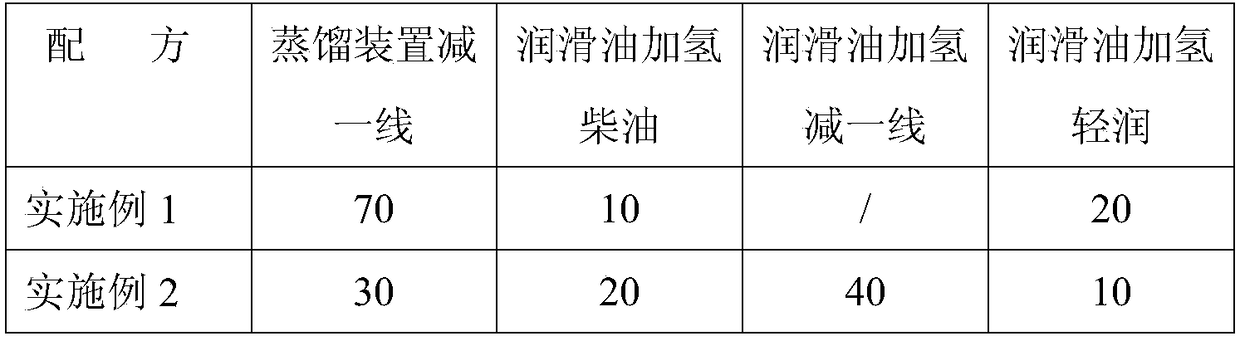

[0031] See Table 2 for an example of the special oil formula for viscous granular emulsified explosives of the present invention:

[0032] Table 2. Special oil formula for viscous granular emulsified explosives of the present invention

[0033]

[0034]

[0035] The above-mentioned raw materials: the first line of distillation unit, the first line of lubricating oil hydrogenation diesel, the first line of hydrogenation of lubricating oil, and the first line of hydrogenation of lubricating oil are all from Jinan Refining and Chemical; the above raw materials can be mixed during preparation.

Embodiment 2

[0037] See Table 3 for examples of explosive formulations prepared with the special oil for viscous granular emulsion explosives of the present invention.

[0038] Table 3. Explosive formula prepared from special oil for viscous granular emulsion explosives of the present invention (the amount of each component is in parts by weight)

[0039] formula

Porous Granular Ammonium Nitrate

special oil

emulsifying base

Example 9

70

Embodiment 1 special oil 4

20

1

Example 10

85

Embodiment 2 special oil 5

30

2

Example 11

65

Embodiment 3 special oil 5

10

1.5

Example 12

80

Embodiment 4 special oil 3.5

15

0.5

Example 13

75

Embodiment 5 special oil 4.5

25

0.8

Example 14

68

Embodiment 6 special oil 4.8

22

1.6

[0040] The preparation method steps of the viscous granular ammonium oil explosive are as follows:

[0041] (1) Start the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com