Polysiloxane block copolymer of grafted cysteine and preparation method and application of polysiloxane block copolymer

A polysiloxane block and cysteine technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

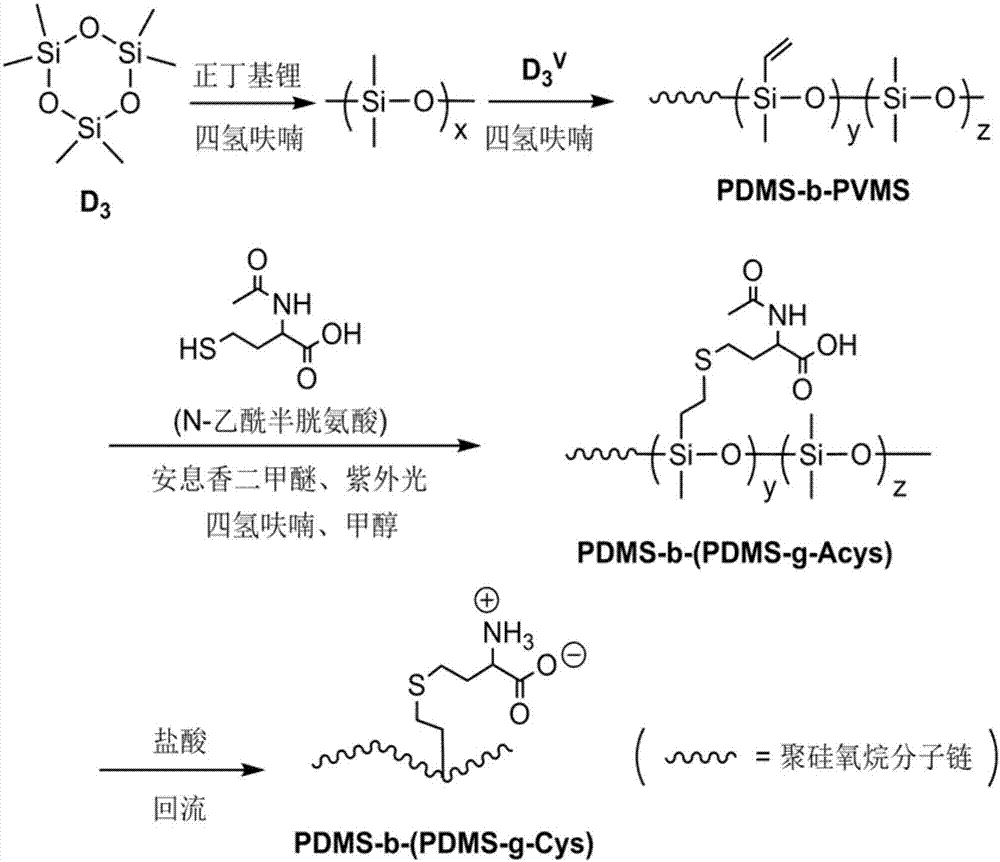

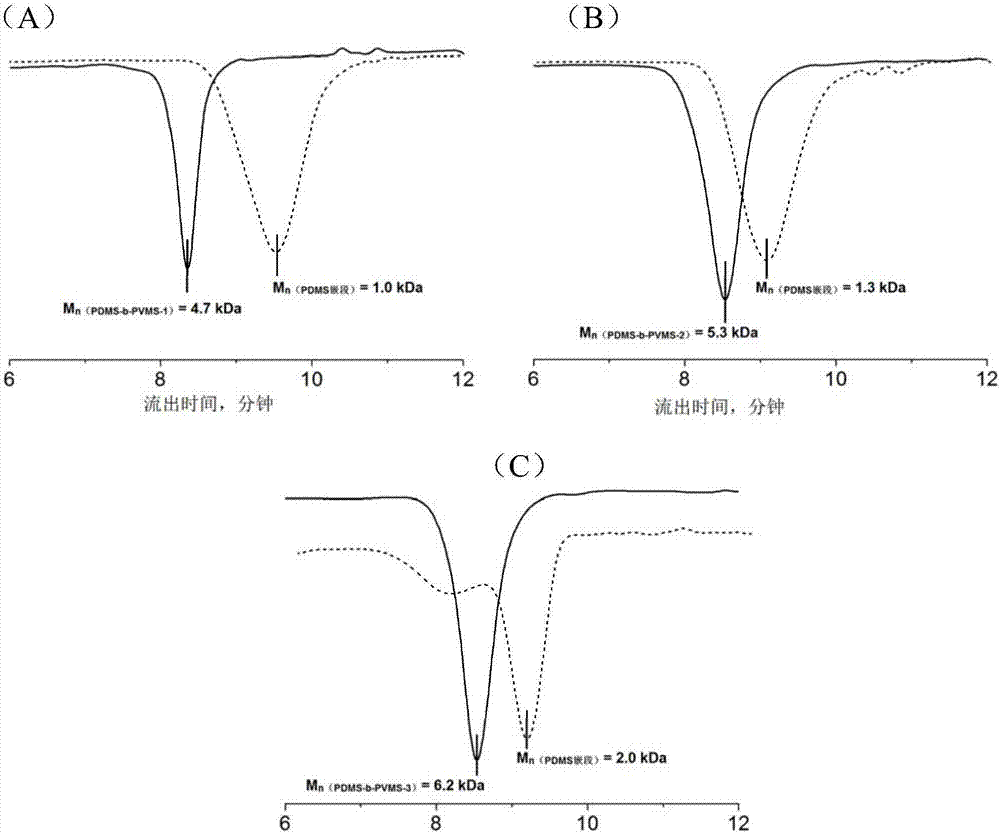

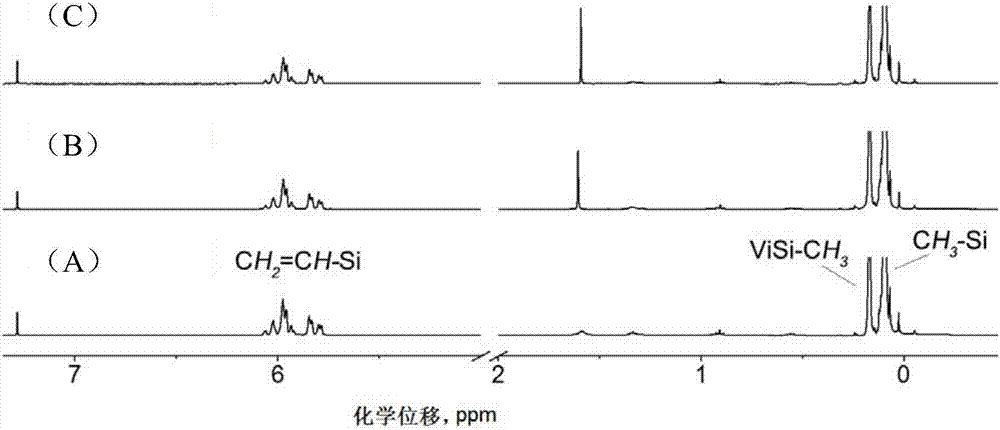

[0054] Preparation of polydimethylsiloxane-polysiloxane grafted cysteine block copolymer: the block length ratio is PDMS:PDMS-g-Cys=1:4, the PDMS block length is 1kDa, and the PDMS- The g-Cys block is 4 kDa long. In the PDMS-g-Cys block, the proportion of the chain segments grafted with cysteine groups to the total number of segments (grafting ratio) is 1 / 2. The preparation process is as figure 1 As shown, the specific steps are as follows:

[0055] (1) In a reaction flask equipped with a magnetic stir bar, add 2.5g D 3 , and then seal it with a silica gel stopper, vacuumize the inside of the bottle and feed high-purity nitrogen, repeat the operation three times to ensure that the bottle is filled with nitrogen. Inject 10 mL of dry tetrahydrofuran into a syringe to dissolve D 3 After obtaining a clear solution, inject 1.0 mL of n-hexane solution containing 2.5 mol / L n-butyllithium at room temperature to initiate anionic ring-opening polymerization. After keeping stirr...

Embodiment 2

[0062] Preparation of polydimethylsiloxane-polysiloxane grafted cysteine block copolymer: the block length ratio is PDMS:PDMS-g-Cys=3:8, the PDMS block length is 1.5kDa, and the PDMS The -g-Cys block is 4 kDa long. In the PDMS-g-Cys block, the proportion of the chain segments grafted with cysteine groups to the total number of segments (grafting ratio) is 1 / 2.

[0063] (1) In a reaction flask equipped with a magnetic stirring bar, add 3.75g D 3 , and then seal it with a silica gel stopper, vacuumize the inside of the bottle and feed high-purity nitrogen, repeat the operation three times to ensure that the bottle is filled with nitrogen. Inject 10 mL of dry tetrahydrofuran into a syringe to dissolve D 3 After obtaining a clear solution, inject 1.0 mL of n-hexane solution containing 2.5 mol / L n-butyllithium at room temperature to initiate anionic ring-opening polymerization. After keeping stirring at 0-5°C for about 12 hours, take a small amount of the reaction solution t...

Embodiment 3

[0068] Preparation of polydimethylsiloxane-polysiloxane grafted cysteine block copolymer: the block length ratio is PDMS:PDMS-g-Cys=1:2, PDMS block length is 2kDa, PDMS- The g-Cys block is 4 kDa long. In the PDMS-g-Cys block, the proportion of the chain segments grafted with cysteine groups to the total number of segments (grafting ratio) is 1 / 2.

[0069] (1) In a reaction flask equipped with a magnetic stir bar, add 5.0g D 3 , and then seal it with a silica gel stopper, vacuumize the inside of the bottle and feed high-purity nitrogen, repeat the operation three times to ensure that the bottle is filled with nitrogen. Inject 10 mL of dry tetrahydrofuran into a syringe to dissolve D 3 After obtaining a clear solution, inject 1.0 mL of n-hexane solution containing 2.5 mol / L n-butyllithium at room temperature to initiate anionic ring-opening polymerization. After keeping stirring at 0-5°C for about 12 hours, take a small amount of the reaction solution to terminate the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com