Transparent cable insulation material and preparation method thereof

A cable insulation and transparent technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of low resistivity, poor toughness, insufficient light transmittance, etc., and achieve good flexibility, high resistivity, high transmittance The effect of light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

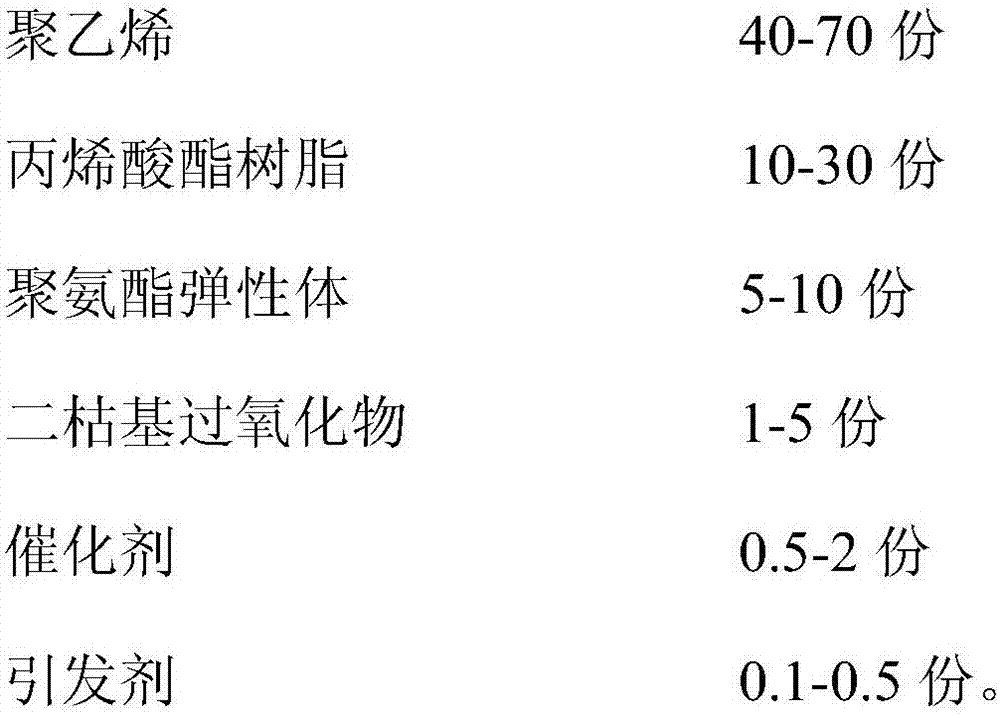

[0042] A transparent cable insulation material, by mass fraction, includes the following components:

[0043]

[0044]The preparation method of the above-mentioned transparent cable insulating material comprises the following steps:

[0045] (1) Add each component of the formula amount into a high-speed mixer, and mix for 10 minutes at a speed of 300r / min;

[0046] (2) Add the mixed material of each component into the twin-screw extruder for reaction extrusion, control the working temperature of the twin-screw extruder to be 180° C., and the residence time of the mixed material in the twin-screw extruder to be 5 minutes, and obtain Transparent cable insulation.

Embodiment 2

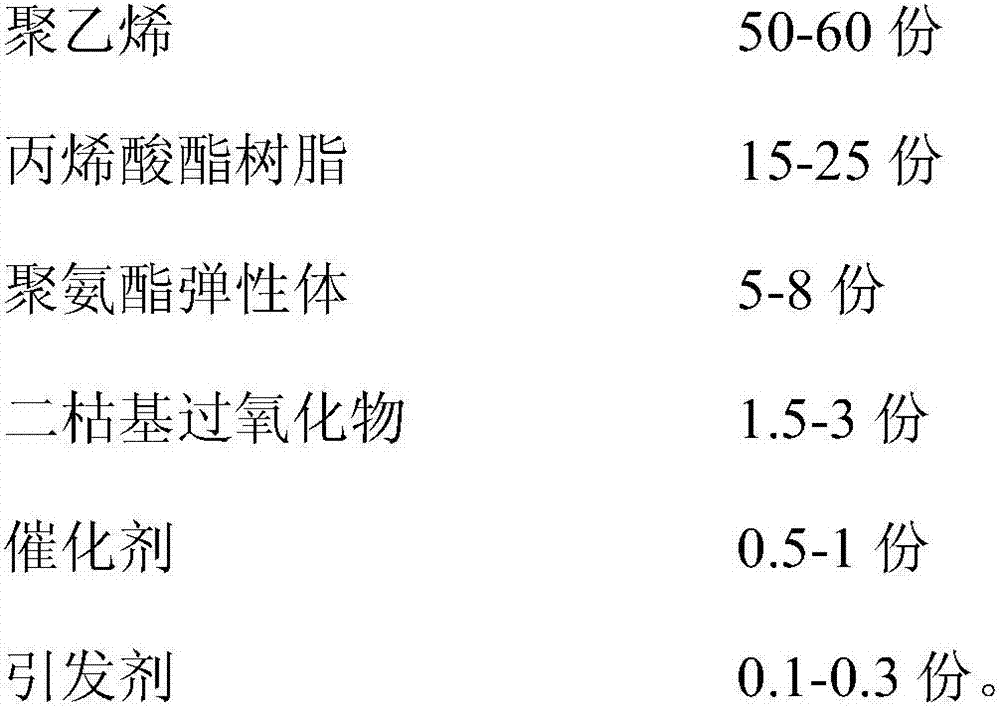

[0048] A transparent cable insulation material, by mass fraction, includes the following components:

[0049]

[0050] The preparation method of the above-mentioned transparent cable insulating material comprises the following steps:

[0051] (1) Add each component of the formula amount into a high-speed mixer, and mix for 5 minutes at a speed of 500r / min;

[0052] (2) Add the mixed material of each component to the twin-screw extruder for reaction extrusion, control the working temperature of the twin-screw extruder to be 230°C, and the residence time of the mixed material in the twin-screw extruder to be 2min, and obtain Transparent cable insulation.

Embodiment 3

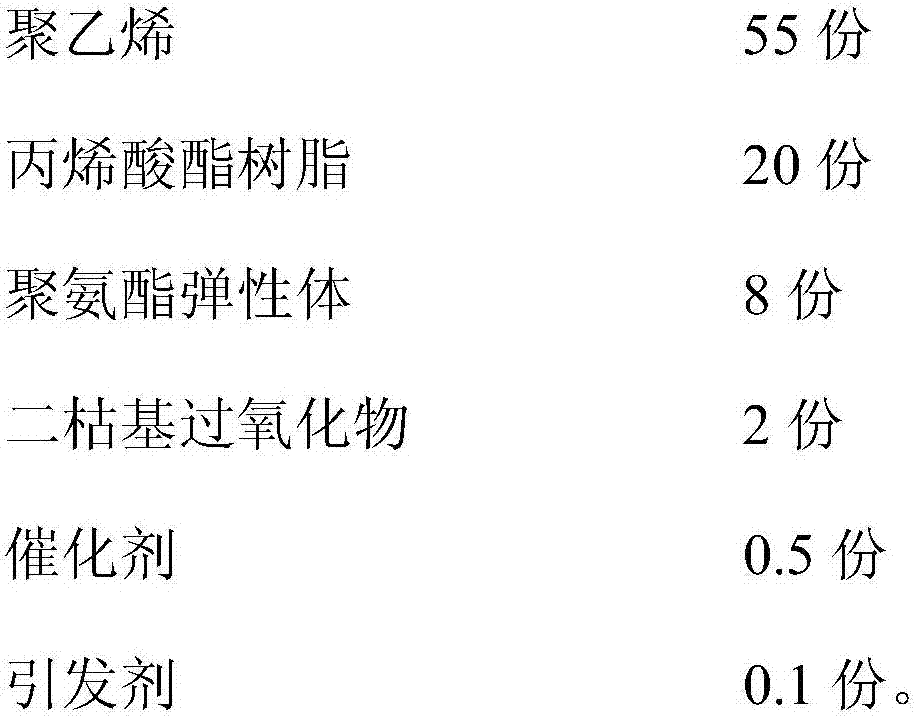

[0054] A transparent cable insulation material, by mass fraction, includes the following components:

[0055]

[0056] The preparation method of the above-mentioned transparent cable insulating material comprises the following steps:

[0057] (1) Add each component of the formula amount into a high-speed mixer, and mix for 8 minutes at a speed of 350r / min;

[0058] (2) Add the mixed material of each component into the twin-screw extruder for reaction extrusion, control the working temperature of the twin-screw extruder to be 200°C, and the residence time of the mixed material in the twin-screw extruder to be 4min, and obtain Transparent cable insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com