Cold in-place recycled emulsified bitumen mixture and cold in-place recycled pavement

A technology of emulsified asphalt and mixture, applied in the direction of coagulation pavement, roads, roads and other directions paved on site, can solve the problems of threshing, loose aggregate, poor cohesion, etc., to improve low temperature flexibility and high temperature stability, The effect of increasing early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

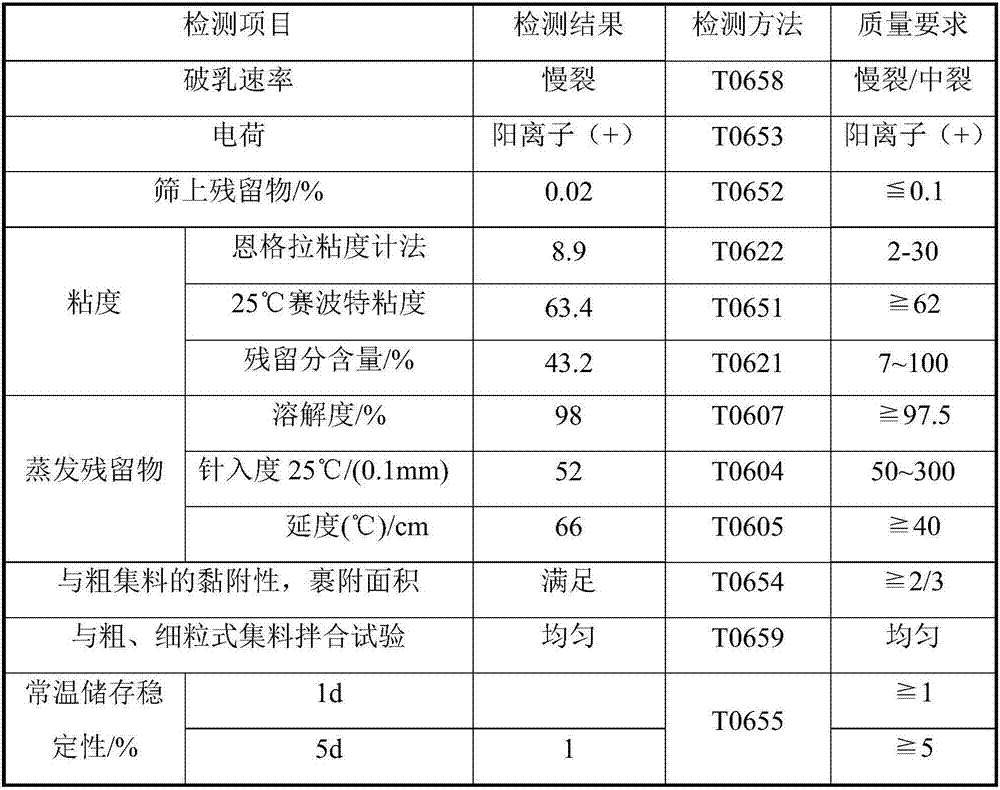

Embodiment 1

[0045] Step 1, 300g tall oil fatty acid is added the iodine of 40g maleic anhydride and 0.6g, in N 2 Under protection, the temperature was raised to 180° C., and the reaction was carried out for 10 hours to obtain a tribasic carboxylic acid intermediate. After heating 240g of triethylenetetramine to 130°C, add 40g of lignin and 25g of paraformaldehyde step by step. After the reaction is carried out for 2 hours, add the pre-prepared tricarboxylic acid intermediate and 4g of silica gel step by step. 2 Under protective conditions, heat up to 170°C, dehydrate for 2 hours, and continue to heat up to 200°C for 2 hours to obtain a lignin cationic emulsifier, which is ready for use.

[0046] Step 2: Add about 170m1 of water to an asphalt emulsifier with an effective content of 50%, and stir gently. After the emulsifier is completely dissolved, adjust the pH of the solution to about 2.0 with concentrated hydrochloric acid, and set the volume to 200m1. Turn on the colloid mill, pour th...

Embodiment 2

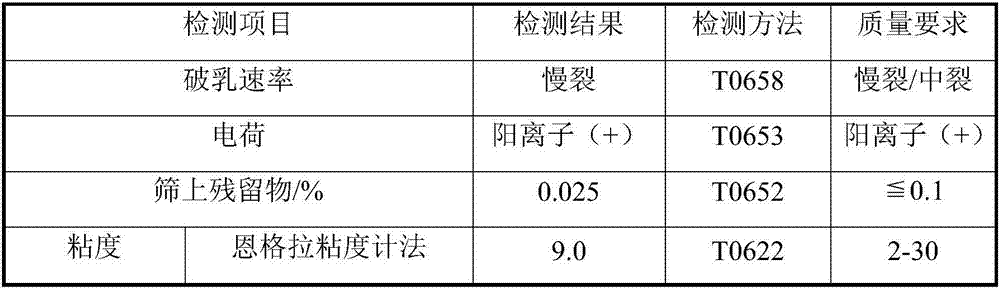

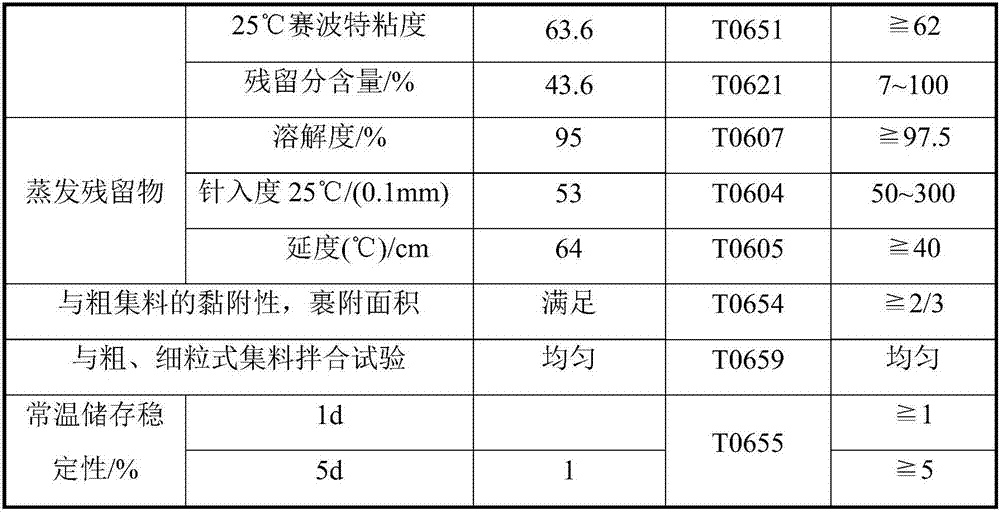

[0052] Step 1, 300g tall oil fatty acid is added the iodine of 40g maleic anhydride and 0.6g, in N 2 Under protection, the temperature was raised to 180° C., and the reaction was carried out for 10 hours to obtain the intermediate of ternary shuttle carboxylic acid. After heating 240g of triethylenetetramine to 130°C, add 40g of lignin and 25g of paraformaldehyde step by step. After the reaction is carried out for 2 hours, add the pre-prepared tricarboxylic acid intermediate and 4g of silica gel step by step. 2 Under protective conditions, heat up to 170°C, dehydrate for 2 hours, and continue to heat up to 200°C for 2 hours to obtain a lignin cationic emulsifier, which is ready for use.

[0053] Step 2: Add about 170m1 of water to an asphalt emulsifier with an effective content of 50%, and stir gently. After the emulsifier is completely dissolved, adjust the pH of the solution to about 2.0 with concentrated hydrochloric acid, and set the volume to 200m1. Turn on the colloid m...

Embodiment 3

[0061] Step 1, 300g tall oil fatty acid is added the iodine of 40g maleic anhydride and 0.6g, in N 2 Under protection, the temperature was raised to 180° C., and the reaction was carried out for 10 hours to obtain the intermediate of ternary shuttle carboxylic acid. After heating 240g of triethylenetetramine to 130°C, add 40g of lignin and 25g of paraformaldehyde step by step. After the reaction is carried out for 2 hours, add the pre-prepared tricarboxylic acid intermediate and 4g of silica gel step by step. 2 Under protective conditions, heat up to 170°C, dehydrate for 2 hours, and continue to heat up to 200°C for 2 hours to obtain a lignin cationic emulsifier, which is ready for use.

[0062] Step 2: Add about 170m1 of water to an asphalt emulsifier with an effective content of 50%, and stir gently. After the emulsifier is completely dissolved, adjust the pH of the solution to about 2.0 with concentrated hydrochloric acid, and set the volume to 200m1. Turn on the colloid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com