Lactose-intolerance fermented milk and preparation method thereof

A fermented milk and lactose-free technology, applied in the direction of bacteria and lactobacilli used in dairy products and food preparation, can solve the problems of complex process, various processing equipment, and harmful microbial erosion, so as not to increase the process and save enzymes Delicate action time and tissue state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the zero-lactose fermented milk, the method comprising the following steps:

[0034] (1) After mixing the raw milk and sugar, a mixed solution is obtained;

[0035] (2) homogenizing the mixed solution, sterilizing, cooling, inoculating the starter, fermenting to an acidity of 70-85 ° T, to obtain a fermented mixed solution;

[0036] (3) Filling the fermented mixture and cooling it twice to obtain the lactose-free fermented milk.

[0037] The zero-lactose fermented milk of the present invention does not add lactase to the raw material, so the enzymatic hydrolysis time of lactase is saved, and the original equipment and process can be used without adding new equipment and process, and the production cost is low and the production cycle is short. .

[0038] Preferably, the homogeneous temperature in step (2) is 60-80° C., and the pressure is 18-20 MPa. The homogeneous condition makes the mixed liquid containing ...

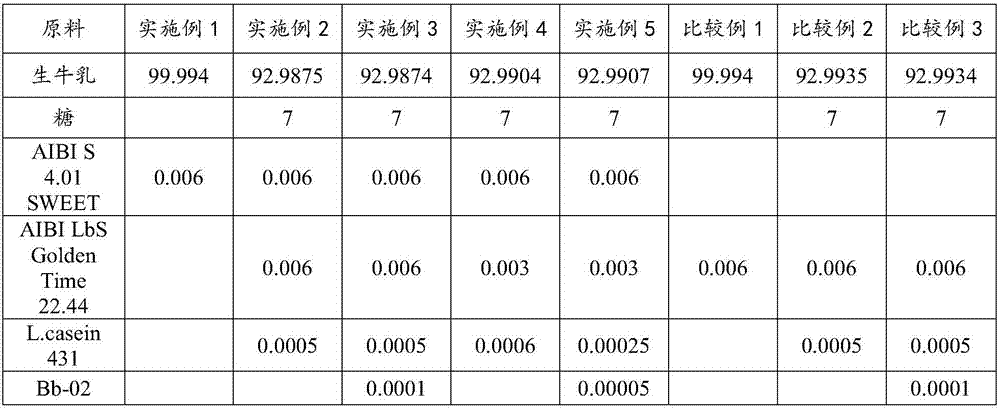

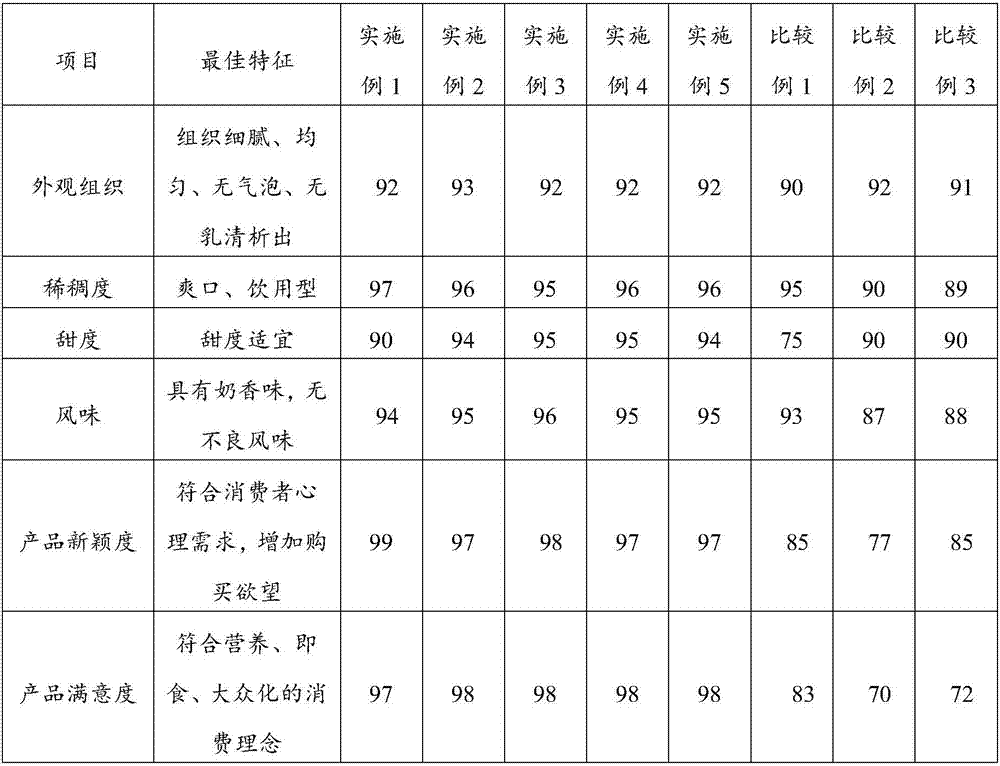

Embodiment 1

[0046] Proportioning was carried out according to the raw materials of Example 1 in Table 1. A method for preparing zero-lactose fermented milk comprises the following steps:

[0047] 1) Preheat raw milk to 70°C and 18MPa for homogenization; sterilize at 110°C for 300s; put the sterilized material into a milk buffer tank and cool to 42°C, inoculate with Streptococcus thermophilus AIBI S 4.01 SWEET at 42°C Ferment for 6.5 hours until the acidity reaches 75°T;

[0048] 2) Aseptic filling is performed when the temperature drops to 15°C, and cooled to 6°C to obtain lactose-free fermented milk.

[0049]The obtained zero-lactose fermented milk was tested for nutritional components, and the test results showed that the protein content was 3.0%, the fat content was 3.1%, and the lactose content was 0.015%.

Embodiment 2

[0051] Carry out proportioning according to the raw material of embodiment 2 in table 1. A method for preparing zero-lactose fermented milk comprises the following steps:

[0052] 1) Preheat raw milk and white sugar to 60°C and mix well;

[0053] 2) Cool to 5°C, stop stirring, temporarily store, homogenize at 70°C and 18MPa, sterilize at 110°C for 300s, put the sterilized material into a milk buffer tank, cool to 44°C, inoculate with Streptococcus thermophilic AIBI S 4.01 SWEET, starter AIBILbS Golden Time 22.44 (including Lactobacillus delbrueckii subspecies bulgaricus and Streptococcus thermophilus), Lactobacillus casein 431, fermented at 44°C for 6 hours until the acidity reached 75°T;

[0054] 3) Aseptic filling is carried out when the temperature drops to 20°C, and the milk is cooled to 2°C to obtain lactose-free fermented milk.

[0055] The prepared zero-lactose fermented milk was tested for nutritional components, and the test results showed that the protein content w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com