Waste mushroom-stick treatment device

A processing device and a technology for waste bacteria sticks, which are applied in the field of waste bacteria stick processing devices, can solve the problems affecting factory cost control, high labor cost, and high labor intensity, and achieve the effects of ensuring work efficiency, improving processing effect, and increasing crushing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

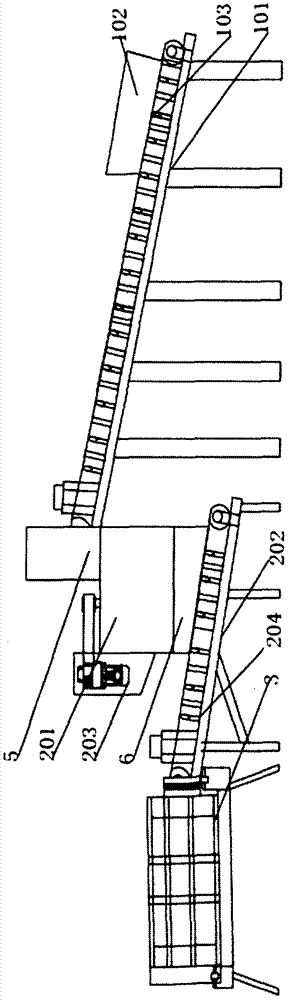

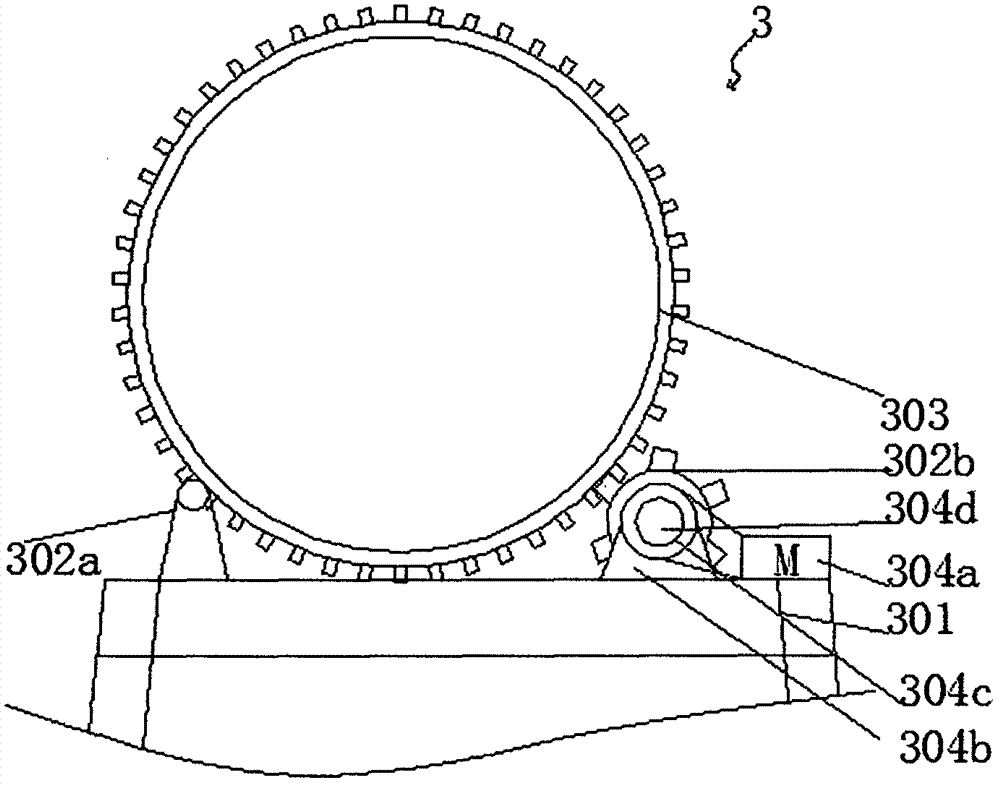

[0019] The first embodiment: a waste fungus bag material bag separation device as shown in the figure, comprising a conveying unit 1, a crushing unit 2, a shaftless drum screen 3;

[0020] The conveying unit 1 includes a conveying rack 101 and a silo 102. The conveying rack 101 is connected with a belt 103 for transmission, and the silo 102 is connected to the end of the belt 103 away from the crushing unit 2;

[0021] The crushing unit 2 includes a crushing box 201, a second conveying frame 202, and a crushing motor 203. The second conveying frame 202 is connected to a belt two 204 for transmission. The crushing box 201 is located above the second belt 204. The motor 203 is fixedly connected to one side of the crushing box 201, and the crushing motor 203 is connected with a rotatable crushing device 4 via a pulley; the second belt 204 extends away from the end of the crushing box 201 into the shaftless drum screen 3.

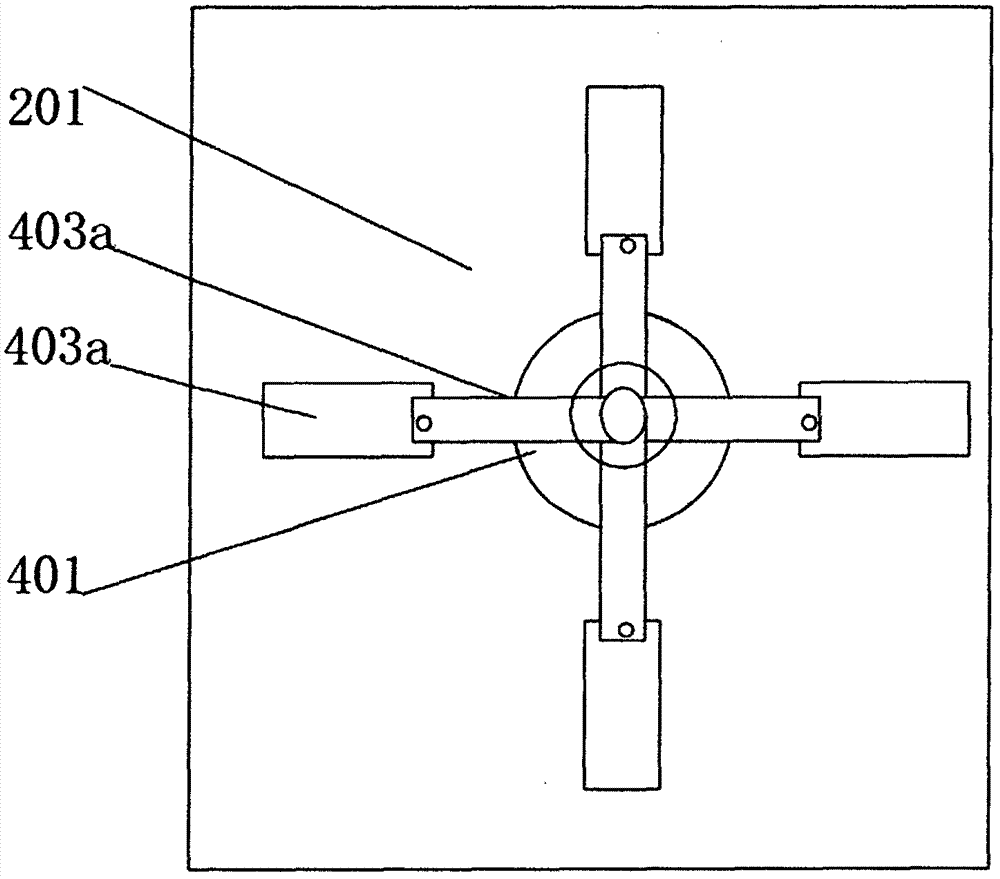

[0022] Preferably, the crushing device 4 includes a bearing seat...

no. 2 example

[0027] Second embodiment: Compared with the first embodiment, the crushing device 4 includes a bearing seat 401 symmetrically fixed to the two ends of the crushing box 201, a rotating shaft 402 is sleeved in the bearing seat 401, and the rotating shaft 402 is sleeved on At least two separating hammers 403 are connected, and the size of the separating hammer 403 located above is smaller than the size of the separating hammer 403 located below. Through layered crushing, the crushing operation of the waste fungus rod can be better completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com