Positive ion type foaming agent for mineral separation

A cationic, foaming agent technology, used in flotation, solid separation, etc., can solve problems such as unfavorable particle adhesion, and achieve the effect of improving recovery rate and efficient mineralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

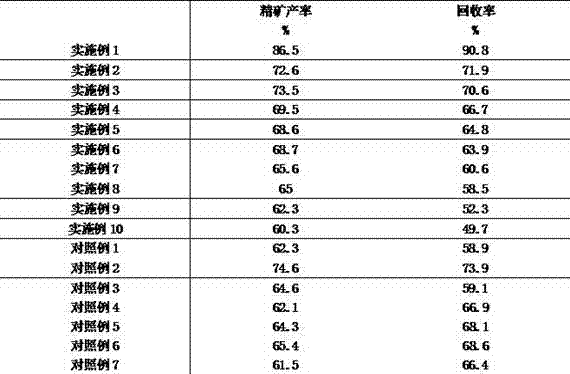

Examples

Embodiment 1

[0013] Embodiment 1: take by weighing pectin, cetyltrimethylammonium bromide and methyl isobutyl carbinol and emulsifier according to the mass ratio of 1:7:1:1, wherein water and emulsifier according to 1 : 1 ratio for preparation, mixed according to the following steps:

[0014] Step 1: put sorbitan trioleate and water in a mixing tank according to a certain mass ratio, stir at a high speed of >5000r / min for 30min, and initially obtain an emulsion of sorbitan trioleate;

[0015] Step 2: Place the ultrasonic probe about 2-3cm below the liquid surface, and turn on the ultrasonic equipment with a power of 540W and an ultrasonic time of 20 minutes. The oil droplets are dispersed into smaller micro-oil droplets under the action of ultrasonic;

[0016] Step 3: Heating the emulsion obtained in Step 2 by program heating, stirring slowly and keeping it at 100 degrees Celsius for 3 hours;

[0017] Step 4: Add pectin to the emulsion obtained in step 3 according to a certain mass ratio,...

Embodiment 2

[0025] Embodiment 2: according to 1:5:2:2, take gentamicin, cetyltrimethylammonium bromide and methyl isobutyl carbinol and emulsifier, according to the steps described in Example 1, prepare Foaming agent.

Embodiment 3

[0026] Embodiment 3: according to 1:5:1:3, take pectin, cetyltrimethylammonium bromide and methyl isobutyl carbinol and emulsifier, according to the steps described in Example 1, prepare Foaming agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com