Milling cutter of son and mother blade structure

A kind of technology of milling cutter and mother-in-law, which is applied in the field of milling cutters with auxiliary cutting sipes with spiral straps. It can solve the problems of insufficient rigidity, uneven cutting edge resistance, and reduced processing surface quality, so as to improve the performance of shock resistance and wear resistance. Effect of reducing cutting resistance and improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

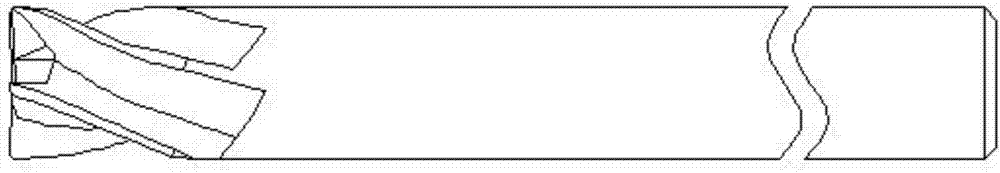

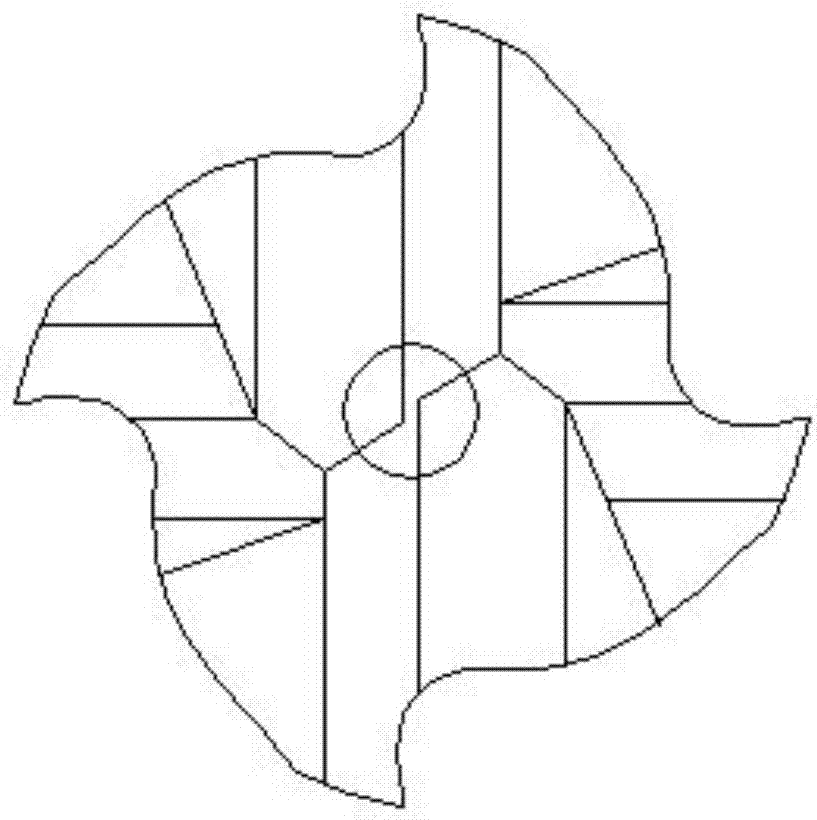

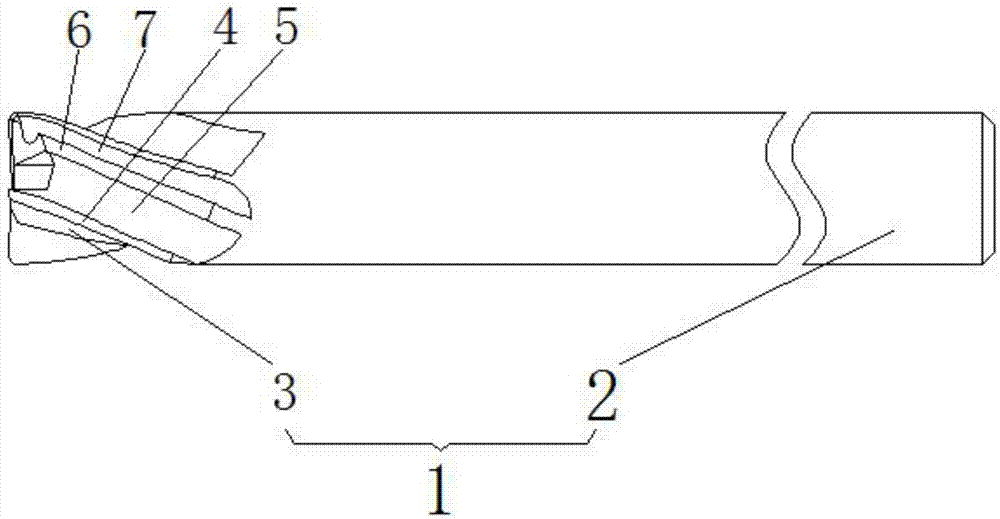

[0019] Embodiment 1: A milling cutter with a sub-female blade structure of the present invention includes a cutter body 1, and the cutter body includes a cutter base 2 arranged at the tail end of the cutter body 1 and a cutter head 3 arranged at the front end; The cutter head 3 is provided with four main cutting edges 4 that are uniformly distributed in a counterclockwise helical shape, and the clockwise front side of each main cutting edge 4 is provided with a main cutting groove 5; Minor cutting edges 6 are provided on the clockwise rear sides of the cutting edges 4 , and minor cutting grooves 7 are formed between the adjacent major cutting edges 4 and minor cutting edges 6 . The included angle between each major cutting edge 4 and the minor cutting edge 6 located at the rear side in the clockwise direction is 30°; the end of the minor cutting edge 6 is lower than the end of the major cutting edge 4 .

Embodiment 2

[0020] Embodiment 2: A milling cutter with a sub-matrix blade structure of the present invention includes a cutter body 1, and the cutter body includes a cutter base 2 arranged at the tail end of the cutter body 1 and a cutter head 3 arranged at the front end; The cutter head 3 is provided with four main cutting edges 4 that are uniformly distributed in a counterclockwise helical shape, and the clockwise front side of each main cutting edge 4 is provided with a main cutting groove 5; Minor cutting edges 6 are provided on the clockwise rear sides of the cutting edges 4 , and minor cutting grooves 7 are formed between the adjacent major cutting edges 4 and minor cutting edges 6 . The included angle between each major cutting edge 4 and the minor cutting edge 6 located at the rear side in the clockwise direction is 30°; the ends of the minor cutting edges 6 are flush with the ends of the major cutting edges 4 .

Embodiment 3

[0021] Embodiment 3: A milling cutter with a sub-matrix blade structure of the present invention includes a cutter body 1, and the cutter body includes a cutter base 2 arranged at the tail end of the cutter body 1 and a cutter head 3 arranged at the front end; The cutter head 3 is provided with four main cutting edges 4 that are uniformly distributed in a counterclockwise helical shape, and the clockwise front side of each main cutting edge 4 is provided with a main cutting groove 5; Minor cutting edges 6 are provided on the clockwise rear sides of the cutting edges 4 , and minor cutting grooves 7 are formed between the adjacent major cutting edges 4 and minor cutting edges 6 . The included angle between each major cutting edge 4 and the minor cutting edge 6 located at the rear side in the clockwise direction is 35°; the end of the minor cutting edge 6 is lower than the end of the major cutting edge 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com