Heavy lanthanum flint optical glass

An optical glass and flint technology, applied in optics, optical components, instruments, etc., can solve the problems of poor anti-devitrification performance, high platinum occupancy, and reduced transmittance, and achieve the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

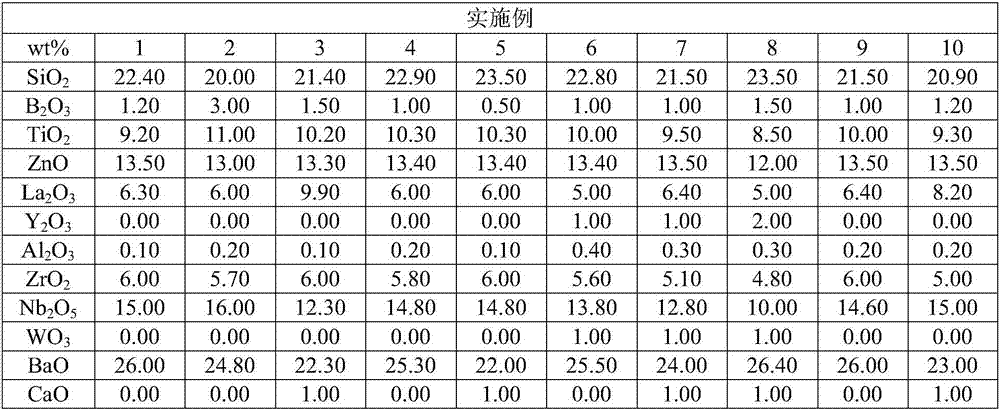

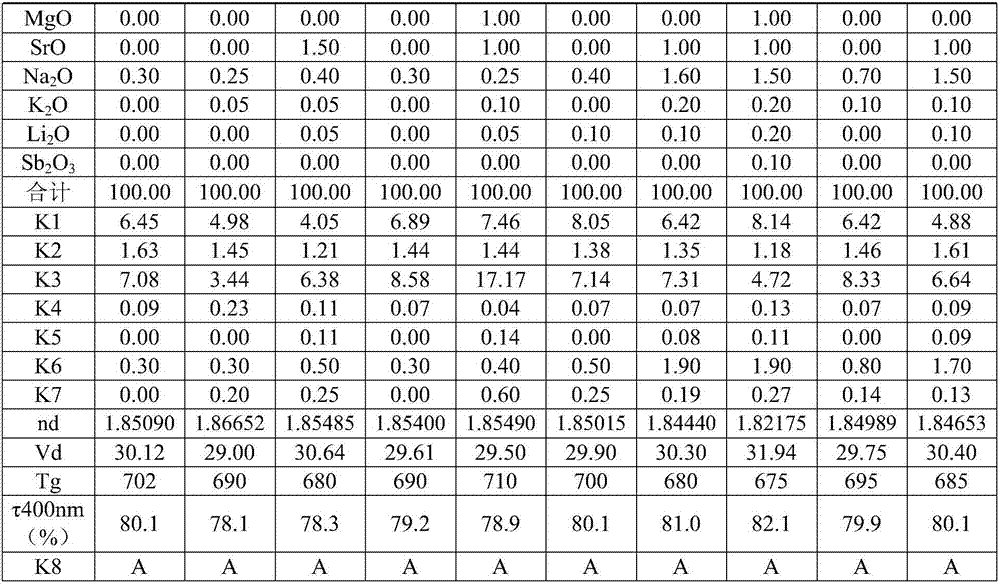

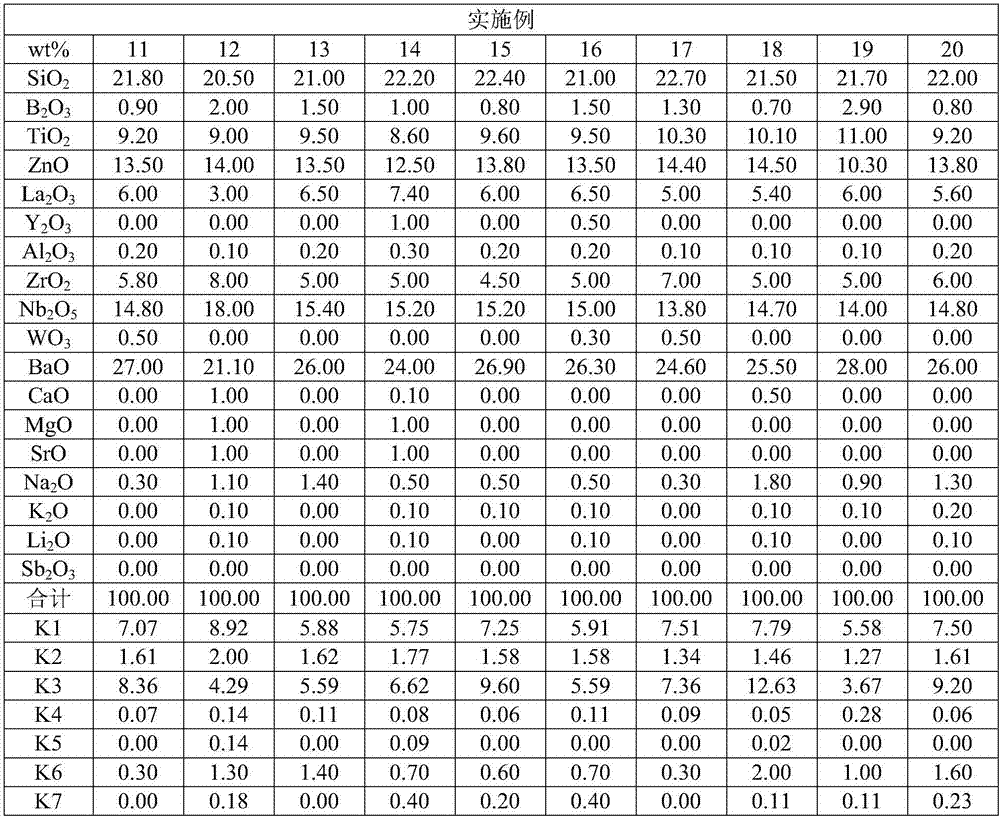

Examples

Embodiment Construction

[0031] Each component of the glass of the present invention will be described below, and the content of each component is expressed in % by weight unless otherwise specified.

[0032] The glass of the present invention is mainly composed of SiO 2 、TiO 2 , ZnO, Nb 2 o 5 And RO (R0 is one or more of MgO, CaO, SrO, BaO, hereinafter the same), etc., through different ratios of reasonable oxides, a refractive index of 1.82-1.87 and an Abbe number of 28-32 are formed Optical glass, and can be used for continuous smelting production of primary chemical platinum, and the cost of raw materials is low.

[0033] If the glass is required to erode the refractory bricks that make up the chemical tank less at the temperature of the chemical material, this requires that on the one hand, the content of the components that are more corrosive to the refractory bricks in the glass components is relatively small, and on the other hand, the glass is at a chemical temperature. The viscosity at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com