Preparation method of original ecological cold-pressed camellia oil and camellia oil

An original ecological, cold-pressed technology, applied in the direction of fat oil/fat refining, fat production, fat oil/fat production, etc., can solve the problems of high investment cost of vacuum freeze-drying technology, not suitable for industrial production, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The specific embodiment of the present invention provides a preparation method of original ecological cold-pressed camellia oil, and the preparation method comprises the steps:

[0021] S1. After the mature organic fresh Camellia oleifera fruit is spread out and aired naturally, air-dried until the husk is automatically cracked, and separated to obtain Camellia oleifera seeds with shells; wherein, natural air-drying specifically refers to air-drying under the conditions of no precipitation and a temperature above 0 degrees .

[0022] S2. After the shelled camellia seeds are processed by screening, air separation, magnetic separation and color sorting, impurities and mildewed shelled camellia seeds are removed.

[0023] S3. Wash the remaining shelled Camellia oleifera seeds in S2 with soft water obtained by ion exchange treatment, place and dry naturally.

[0024] S4, drying the Camellia oleifera seeds with shells after natural drying at low temperature in a drying room...

Embodiment 1

[0035] S1. Spread out the mature camellia oleifera fruit to dry naturally and then air-dry until the husk is automatically split, and separate the camellia oleifera seeds with shells.

[0036] S2. After the shelled camellia seeds are processed by screening, wind separation, magnetic separation, color sorting and other processes, the impurities and mildewed camellia seeds mixed in the camellia oleifera seeds are removed, and the good shelled camellia oleifera seeds are retained.

[0037] S3. Wash the camellia oleifera seeds with ion-exchanged soft water and place them to dry naturally.

[0038] S4, drying the camellia oleifera seeds with shells at low temperature, laying the camellia oleifera seeds in the drying room with a thickness of ≤20cm, the temperature of the drying room at 40°C, and reducing the moisture content of the camellia oleifera seeds to 8% to 10% to complete the drying process.

[0039] S5. The camellia oleifera seeds are directly pressed by a cold press and th...

Embodiment 2~5

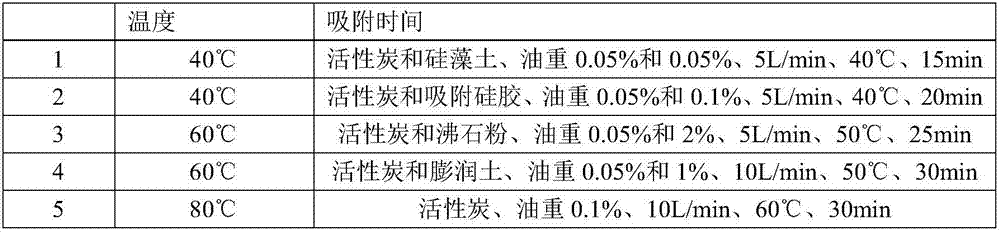

[0043] Using basically the same method as Example 1, the original cold-pressed camellia oil of Examples 2-5 was prepared. The difference from Example 1 is: drying chamber temperature in step S4, adsorbent type, adsorbent dosage, nitrogen flow rate, adsorption temperature, adsorption time, etc. in step S7, as shown in Table 1.

[0044] Table 1 The main process conditions for the preparation of the original ecological cold-pressed camellia oil

[0045]

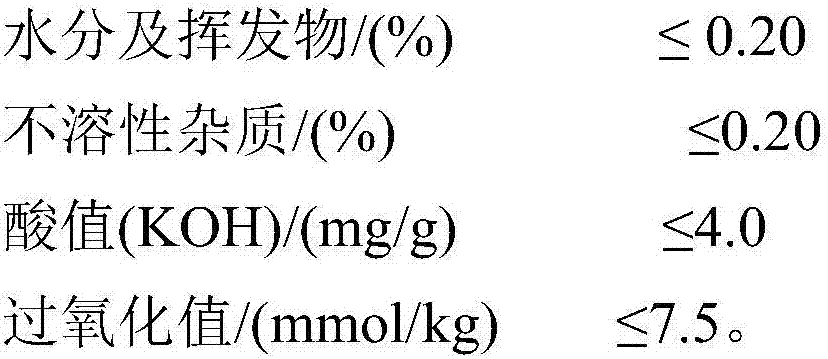

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com