Land test stand system for large and medium-sized combustion gas turbine

A technology of gas turbine and test bench, which is applied in the direction of engine testing, machine/structural component testing, instruments, etc. It can solve the problems of occupational health hazards for field workers, large and medium-sized gas turbines with large output power, and high heat radiation temperature. The effects of low health hazards, complete supporting subsystems, and low human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make it easier to understand and master the technical measures, creation features, functions and advantages of the large and medium-sized gas turbine land test bench system, the system will be further described in combination with specific implementation methods.

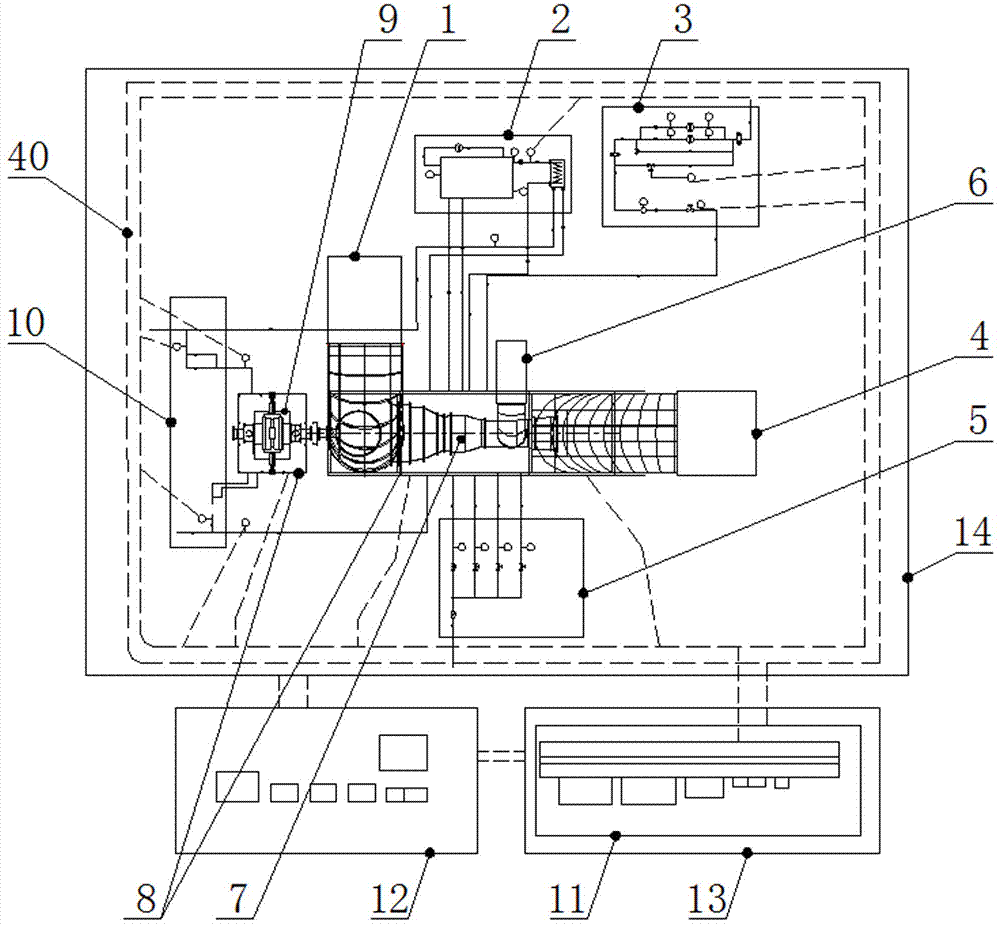

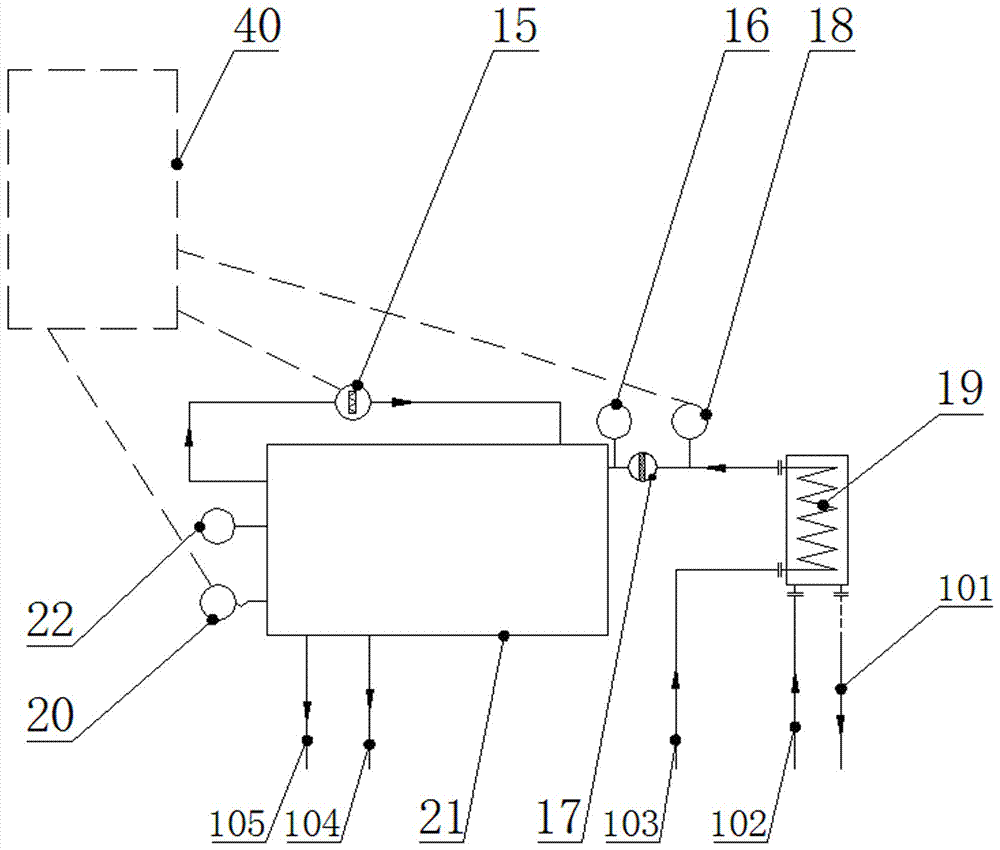

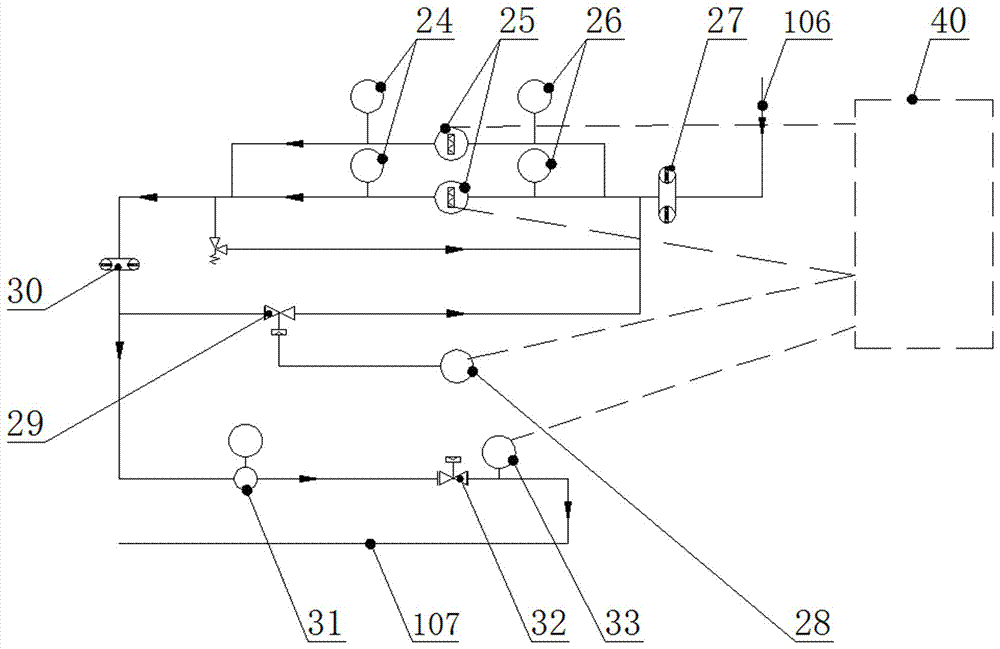

[0025] Referring to each figure, the land test bench system includes a test site 14, an electrical equipment room 12, and a commissioning and operating room 13, wherein the test site includes a gas turbine main body 7, a test bench base frame 8, an exhaust device 1, an air intake device 4, an ejector Device 6, oil skid 2, fuel oil skid 3, compressed air system 5, circulating water system 10 and hydraulic dynamometer 9; pedestal; the electrical equipment room 12 adopts a distributed regional power distribution mode, including a DC power box and an AC power distribution box, which provide power for monitoring, fire protection, and other electrical equipment; the debugging operation room 13 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com