Vacuum brazing method of double-path rotating joint

A technology of rotary joints and brazing methods, which is applied to circuits, welding equipment, electrical components, etc., can solve problems such as corrosion, difficulty in ensuring cavity size accuracy, and reduced service life, and achieve automatic positioning and assembly accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

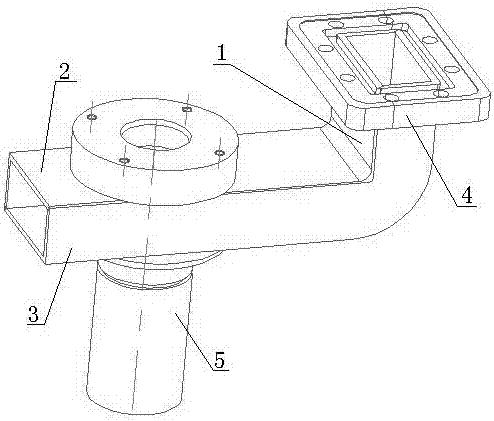

[0024] Such as figure 1 Shown, a kind of two-way rotary joint vacuum brazing method, it comprises the following steps:

[0025] S1. Processing of the upper cover plate: water cutting preparation; CNC rough milling the six sides of the preparation; annealing at a temperature of 250~280°C to eliminate stress; CNC fine milling preparation six sides; fine milling on the bottom surface of the preparation Process the annular shoulder arranged around the edge of the stock; deburr; finally realize the processing of the upper cover plate 1;

[0026] S2. Processing of the middle cover plate: preparation by water cutting; six surfaces of preparation by CNC rough milling; annealing at a temperature of 250~280°C to eliminate stress; six surfaces of preparation by CNC fine milling; fine milling on the bottom surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com