Surface grinding device and planetary wheel

A technology of plane grinding and star wheel, which is applied in the field of star wheel, can solve the problems of inability to measure thickness and poor working efficiency, and achieve the effect of preventing deformation and damage, reducing working hours, and realizing the effect of grinding and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

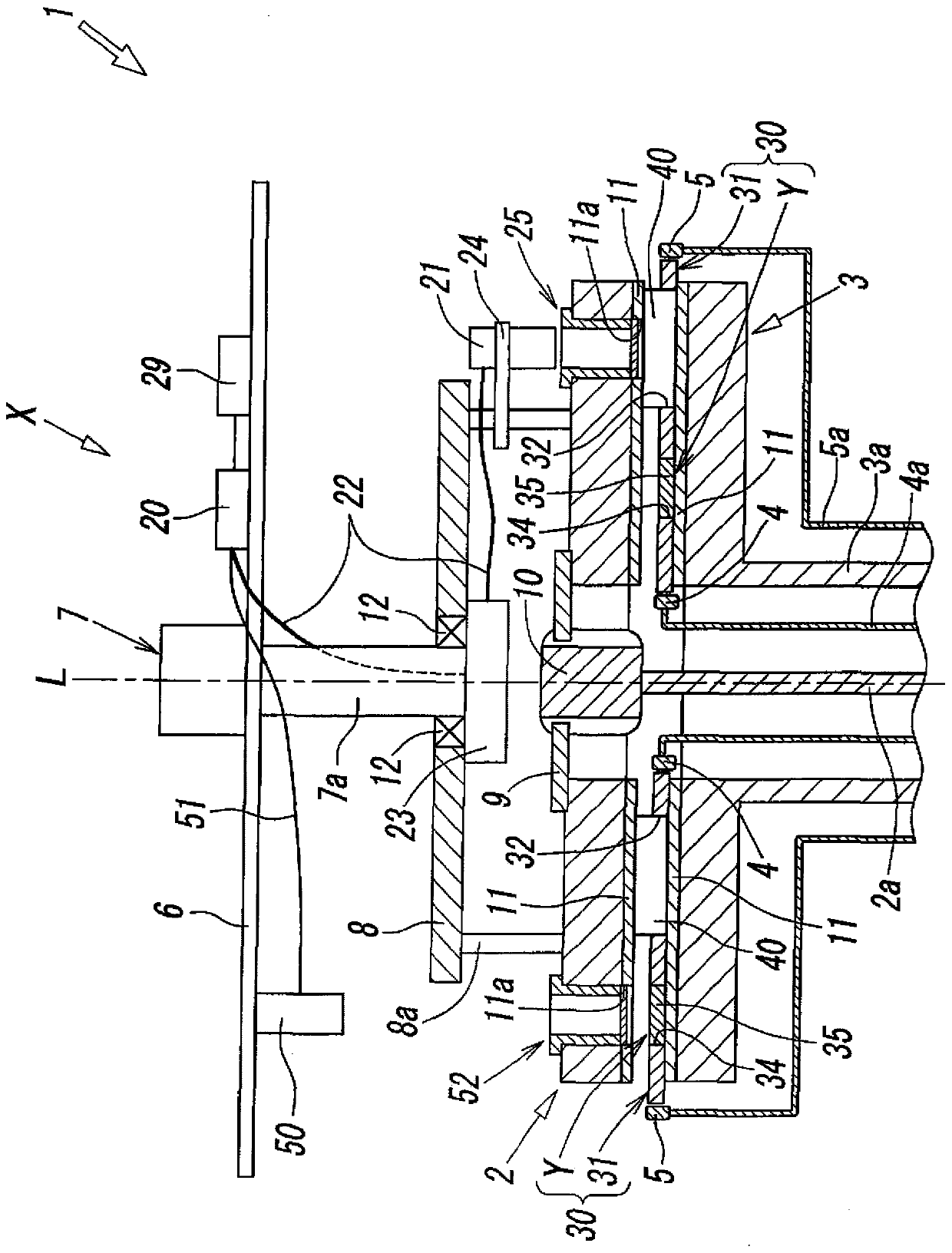

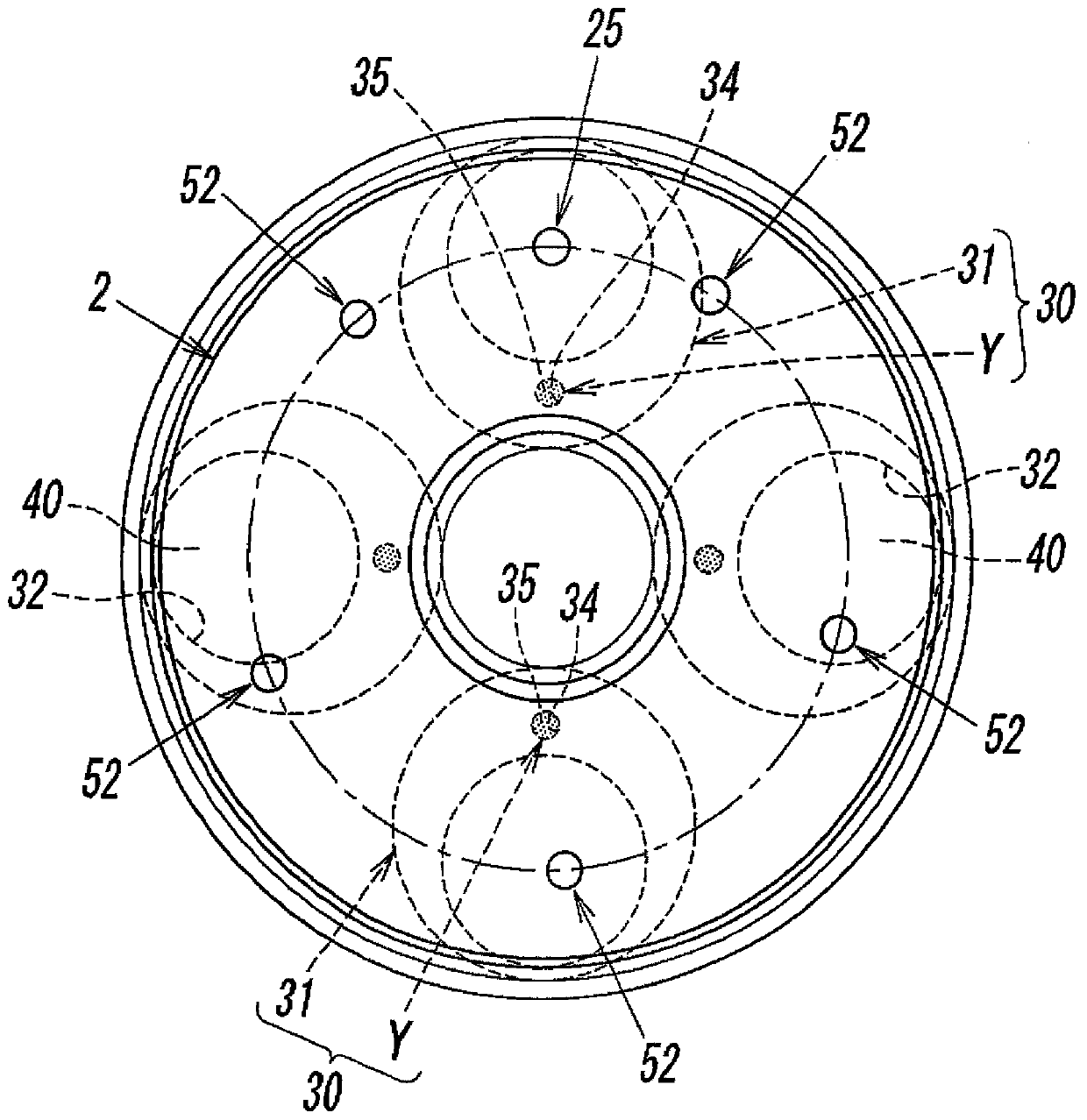

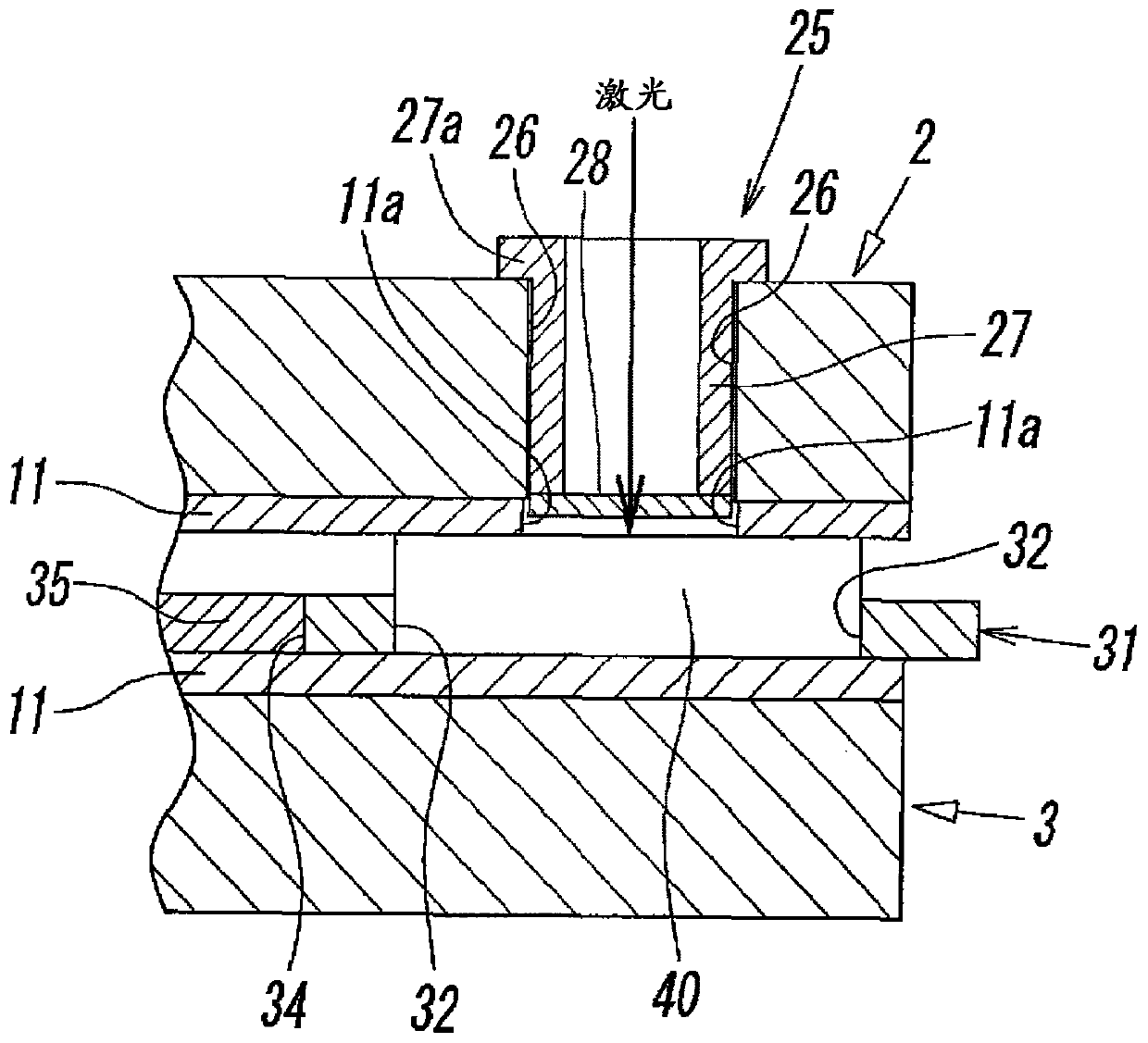

[0039] One embodiment of the plane polishing device of the present invention will be described in detail below using the drawings. The surface grinding device 1 of the present embodiment is used to grind the front and back surfaces of a light-transmitting (light-transmitting) plate-shaped workpiece 40 such as a silicon wafer or a glass substrate. figure 1 As shown, there are an upper fixed plate 2, a lower fixed plate 3, a sun gear (sun gear) 4, and an internal gear (internal gear) 5, which are rotatably arranged on the body of the plane grinding device 1 around the axis L, and have Metal planetary gears 30 are placed on the lower fixed plate 3 at equal intervals and mesh with the sun gear 4 and the internal gear 5 . A workpiece holding hole 32 for holding the above-mentioned workpiece 40 is formed in the planetary wheel 30 .

[0040] In addition, the surface grinding device 1 has a first drive shaft 2a, a second drive shaft 3a, a third drive shaft 4a, and a fourth drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com