Treatment method for improving weaving property of amorpha fruticosa twigs

A processing method and technology of Amorpha japonica, applied in the direction of wood treatment, wood heat treatment, wood treatment details, etc., can solve problems such as increasing weaving cost, breakage, and damage to weaving personnel, and achieve improved dimensional stability, extended service life, and moisture absorption. Sexually diminished effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

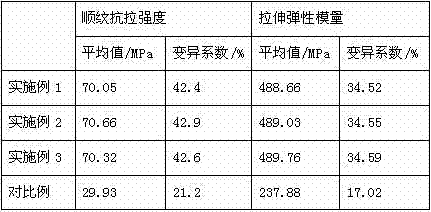

Examples

Embodiment 1

[0015] In the embodiment of the present invention, a processing method for improving the weaving performance of amorpha bark, the specific method is as follows:

[0016] (1) Remove the roots and leaves of the Amorpha fragrans bark, soak it in a potassium nitrate solution with a mass fraction of 1.5% for 45 minutes, take out the filtrate, and treat it with constant temperature steam for 18 minutes at a temperature of 180 ° C, take it out, and put it in a temperature of Drying at 64°C until the moisture content is 19% to obtain pretreated Amorpha fruticosa strips;

[0017] (2) Submerge the pretreated Amorpha fruticosa strips in the treatment agent for 39 minutes, and pass through ultrasonic waves for ultrasonic treatment. The filter agent is taken out, and treated with constant temperature steam for 5 minutes at a temperature of 132°C, with a heating rate of 5.4°C / min Raise the temperature to 174°C and continue the steam treatment at constant temperature for 8 minutes, then trea...

Embodiment 2

[0023] In the embodiment of the present invention, a processing method for improving the weaving performance of amorpha bark, the specific method is as follows:

[0024] (1) Remove the roots and leaves of the Amorpha fragrans strips, immerse them in a potassium nitrate solution with a mass fraction of 1.6% for 48 minutes, take out the filtrate, and treat it with constant temperature steam for 18.5 minutes at a temperature of 181°C. drying at 65°C until the moisture content is 20%, to obtain pretreated Amorpha fruticosa strips;

[0025] (2) Submerge the pretreated Amorpha fruticosa strips in the treatment agent for 40 minutes, and pass through the ultrasonic wave for ultrasonic treatment. The filter agent is taken out, and the temperature is 133 ° C. Raise the temperature to 175°C and continue the constant temperature steam treatment for 8.5min, then treat at a constant pressure of 2.6MPa for 15.5min, increase the pressure at a rate of 0.35MPa / min to 7.5MPa and continue the con...

Embodiment 3

[0031] In the embodiment of the present invention, a processing method for improving the weaving performance of amorpha bark, the specific method is as follows:

[0032] (1) Remove roots and leaves from Amorpha fragrans strips, immerse them in a potassium nitrate solution with a mass fraction of 1.7% for 50 minutes, take out the filtrate, and treat it with constant temperature steam for 19 minutes at a temperature of 182°C. Drying at 66°C until the moisture content is 21% to obtain pretreated Amorpha fruticosa strips;

[0033] (2) Submerge the pretreated Amorpha fruticosa strips in the treatment agent for 41 minutes, and pass through the ultrasonic wave for ultrasonic treatment, take out the filter agent, and treat it with constant temperature steam for 6 minutes at a temperature of 134 °C, at a heating rate of 5.8 °C / min Raise the temperature to 176°C and continue the constant temperature steam treatment for 9 minutes, and then continue the constant pressure treatment at a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com