Reinforcing and toughening method for annual green bamboo

A technology for strengthening, toughening, and greening bamboo, which can be used in reed/straw treatment, wood treatment, wood heating, etc. It can solve problems such as reducing land use efficiency and prolonging bamboo cultivation time, improving land resource use efficiency and brightening appearance. , not easy to decompose and break the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

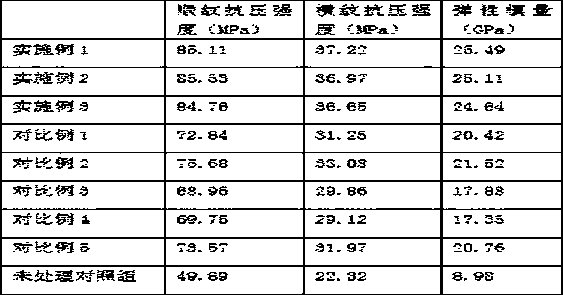

Examples

Embodiment 1

[0017] In an embodiment of the present invention, a method for strengthening and toughening annual green bamboo, the specific method is as follows:

[0018] (1) Cut the felled annual green bamboo into segments, immerse in an aqueous solution of calcium formate with a temperature of 49°C and a mass fraction of 5.1% for 28 minutes, take out the filtrate, steam it, and take it out;

[0019] (2) Submerge the annual green bamboo treated in step (1) in the impregnating agent for 180 minutes, and remove the filter agent;

[0020] The impregnating agent is made of the following raw materials in parts by weight: 5.3 parts of sodium hexametasulfate, 4.2 parts of sodium benzoate, 7.1 parts of iron pyrophosphate, 1.2 parts of aloe polysaccharide, 1.5 parts of fungus polysaccharide, 4.4 parts of propolis, and 74 parts of water ;

[0021] (3) The annual green bamboo treated in step (2) is subjected to electric field treatment, and dried for 32 minutes at a temperature of 37°C.

[0022] As...

Embodiment 2

[0026] In an embodiment of the present invention, a method for strengthening and toughening annual green bamboo, the specific method is as follows:

[0027] (1) Cut the felled annual green bamboo into segments, immerse it in an aqueous solution of calcium formate with a temperature of 51°C and a mass fraction of 5.3% for 30 minutes, remove the filtrate, steam it, and take it out;

[0028] (2) Submerge the annual green bamboo treated in step (1) in the impregnating agent for 190 minutes, and remove the filter agent;

[0029] The impregnating agent is made of the following raw materials in parts by weight: 5.5 parts of sodium hexametasulfate, 4.3 parts of sodium benzoate, 7.4 parts of iron pyrophosphate, 1.3 parts of aloe polysaccharide, 1.6 parts of fungus polysaccharide, 4.6 parts of propolis, and 76 parts of water ;

[0030] (3) The annual green bamboo treated in step (2) is subjected to electric field treatment, and dried at a temperature of 38° C. for 35 minutes.

[0031]...

Embodiment 3

[0035] In an embodiment of the present invention, a method for strengthening and toughening annual green bamboo, the specific method is as follows:

[0036] (1) Cut the felled annual green bamboo into segments, immerse it in an aqueous solution of calcium formate with a temperature of 53°C and a mass fraction of 5.5% for 32 minutes, take out the filtrate, steam it, and take it out;

[0037] (2) Submerge the annual green bamboo treated in step (1) in the impregnating agent for 200 minutes, and remove the filter agent;

[0038] The impregnating agent is made of the following raw materials in parts by weight: 5.7 parts of sodium hexametasulfate, 4.4 parts of sodium benzoate, 7.7 parts of iron pyrophosphate, 1.4 parts of aloe polysaccharide, 1.7 parts of fungus polysaccharide, 4.8 parts of propolis, and 78 parts of water ;

[0039] (3) The annual green bamboo treated in the step (2) is subjected to electric field treatment, and dried at a temperature of 39° C. for 32 to 38 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com