Acoustic material manufacturing method

A technology of sound-absorbing material and manufacturing method, which is applied to manufacturing tools, paint containing biocide, anti-fouling/underwater coating, etc. Strong performance, good effect of pick and place operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

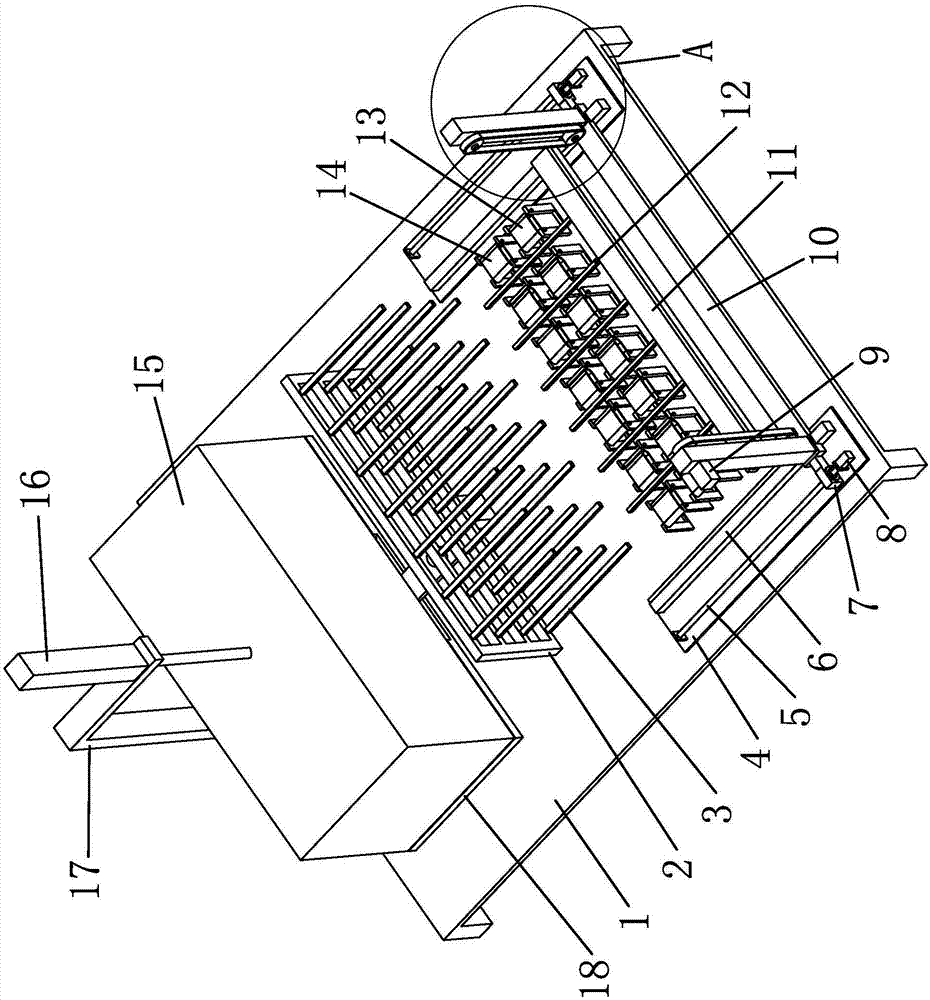

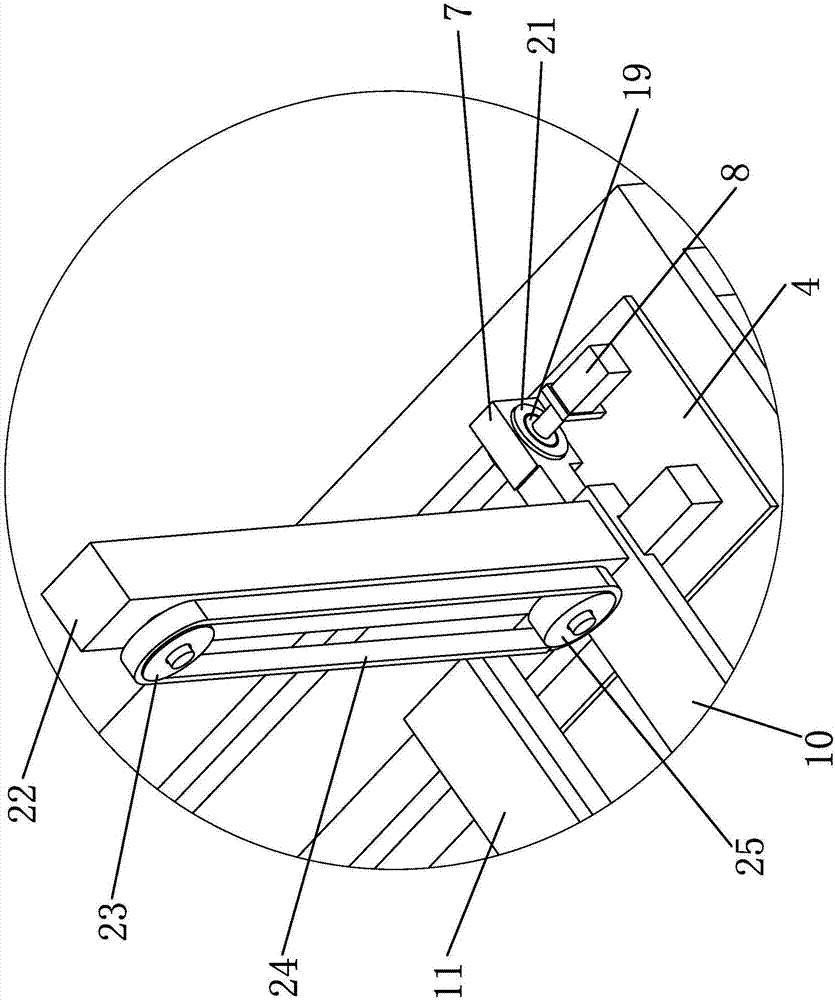

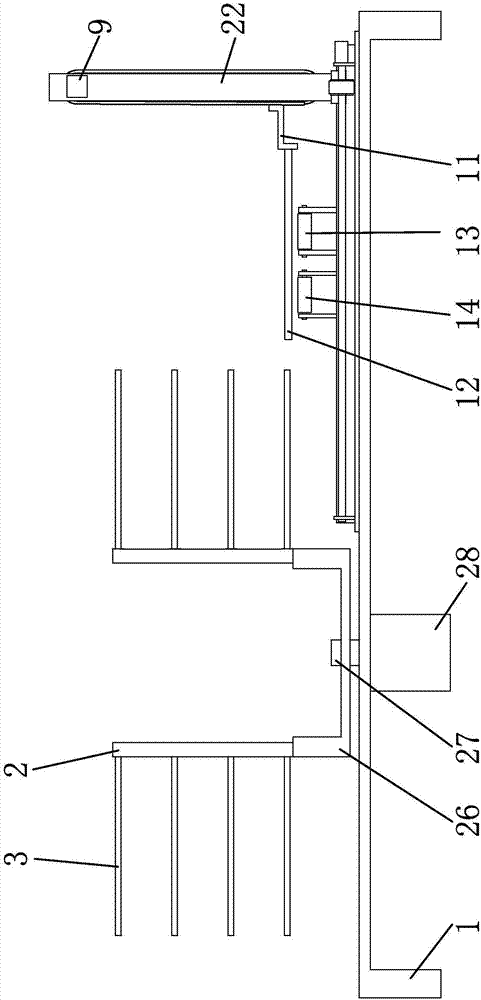

[0056] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0057] The manufacturing method of the sound-absorbing material comprises the following steps:

[0058] a. Weigh the following raw materials in parts by weight: 14-20 parts of cotton fiber, 6-7 parts of glass fiber, 10-14 parts of aluminum fiber, 8-12 parts of gypsum powder, 6-9 parts of asbestos powder, 3-10 parts of wood fiber 2-6 parts, 2-6 parts of nano-carbon, 3-5 parts of magnesium oxide and 1-3 parts of anti-aging agent; 9 parts of gypsum powder, 7 parts of asbestos powder, 5 parts of wood fiber, 3 parts of nano-carbon, 4 parts of magnesium oxide and 1 part of anti-aging agent;

[0059] b. Pour the above raw materials into a blender, the stirring time is 5-15min, and the stirring speed is 150-350r / min to make a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com