Printing and dyeing wastewater purifying flocculating agent, and printing and dyeing wastewater purifying application thereof

A printing and dyeing wastewater and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in meeting industrial scale application, high manufacturing cost, and slow sedimentation rate , to achieve the effect of strong physical adsorption, low price, and accelerated coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

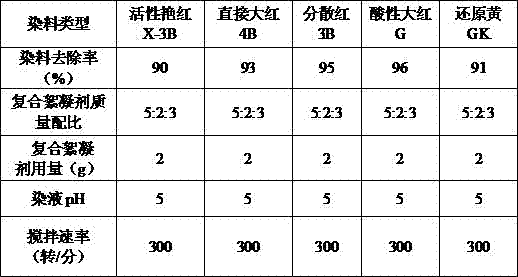

Embodiment 1

[0012] The mixed components of the printing and dyeing wastewater purification flocculant include N-carboxyethyl chitosan, cationic starch and bentonite, wherein,

[0013] Bentonite is preferably purified bentonite. The purification method is as follows: add sodium-based bentonite to water with 20 times the quality of bentonite and stir for 1 hour to form a bentonite suspension. After standing for stratification, remove the supernatant, and the remaining Obtained by drying, grinding, and 200-mesh screening;

[0014] N-carboxyethyl chitosan can be prepared by using the existing N-carboxyethyl chitosan preparation method, and this application has cited a preparation method for N-carboxyethyl chitosan, but this patent application involves N-carboxyethyl chitosan is not limited to this preparation method: Dissolve chitosan in an acrylic acid solution with a mass concentration of 1.5%, prepare a chitosan solution with a concentration of 10%, stir and heat up to 55°C and keep it for...

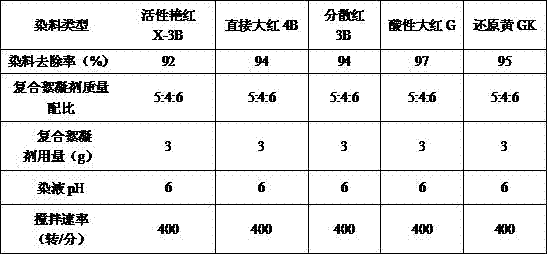

Embodiment 2

[0019] Mixing component is identical with embodiment 1

[0020] Mix the above-mentioned treated bentonite, N-carboxyethyl chitosan and cationic starch according to the mass ratio of 5:4:6, take 3g and add it to the concentration of 50 mg / L, the volume is 1L of each listed in the table below. For various types of dye wastewater, adjust the pH of the wastewater to 6 with hydrochloric acid, stir for 30 minutes, and then settle for no less than 6 minutes. Take the supernatant to measure the liquid absorbance of the supernatant, and calculate its removal of various types of dyes The results are shown in Table 2:

[0021]

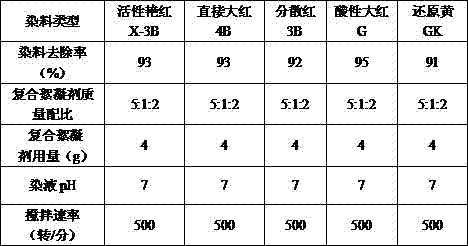

Embodiment 3

[0023] Mixing component is identical with embodiment 1

[0024] The bentonite, N-carboxyethyl chitosan and cationic starch after the above treatment were mixed according to the mass ratio of 5:1:2, and 4 g was added to the following table with a concentration of 50 mg / L and a volume of 1 L. In various types of dye wastewater, adjust the pH of the wastewater to 7 with hydrochloric acid, stir for 30 minutes, and then settle for no less than 6 minutes. Take the supernatant to measure the liquid absorbance of the supernatant, and calculate its specificity for various types of dyes. Removal rate, its result is shown in Table 3:

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com