Fluidized bed boiler denitration device and method based on cyclone separators

A cyclone separator, fluidized bed boiler technology, applied in separation methods, chemical instruments and methods, fluidized bed combustion equipment, etc., can solve problems such as corrosion risk, low reaction, air preheater blockage, etc., and achieve improved denitrification The utilization rate of the agent and the effect of good denitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

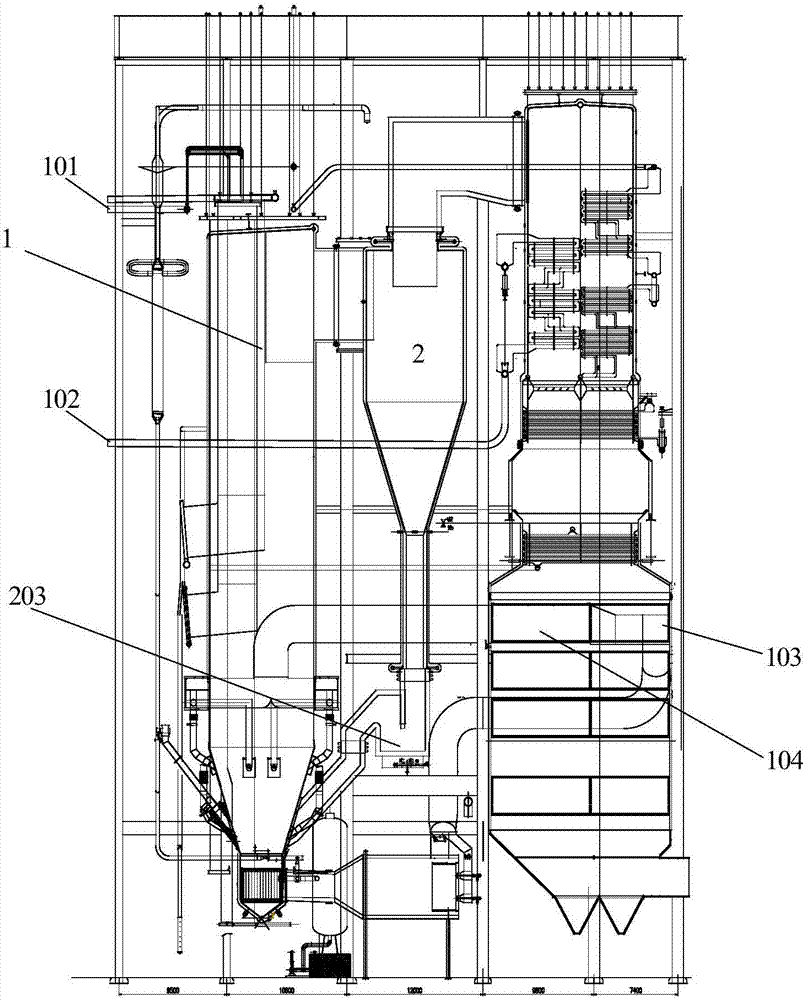

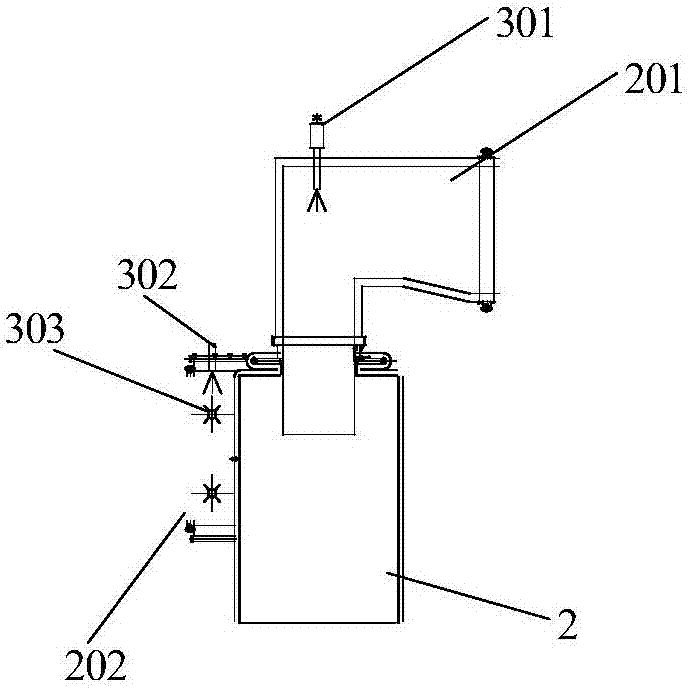

[0036] Such as figure 1 , a fluidized bed boiler denitrification device based on a cyclone separator, the furnace outlet flue of the fluidized bed boiler 1 is connected with a cyclone separator 2, the outlet flue 201 of the cyclone separator is provided with an ammonia gun, and the outlet flue The nozzle of the ammonia gun of the road is downward.

[0037] The fluidized bed boiler 1 is a vertical boiler, and a reheater is arranged on the upper part of the boiler furnace, connecting the reheater inlet 102 and the reheat steam outlet 101; the boiler side wall is provided with a primary air channel 103 and a secondary air channel 104 . The outlet flue of the furnace is connected to three cyclone separators 2 connected in parallel, and the outlet flues of the three cyclone separators are all connected to the boiler tail flue 105, and the bottom feeder 203 of the cyclone separator 2 is connected to the bottom of the rear wall of the boiler furnace . The top of the horizontal sect...

Embodiment 2

[0052] A cyclone separator-based fluidized bed boiler denitrification device, in which three cyclone separators 2 are connected to the furnace flue of the fluidized bed boiler 1 . The fluidized bed boiler 1 is a vertical boiler, and a reheater is arranged on the upper part of the boiler furnace, connecting the reheater inlet 102 and the reheat steam outlet 101; the boiler side wall is provided with a primary air channel 103 and a secondary air channel 104 . Three cyclone separators 2 connected in parallel are installed on the rear wall of the flue, and the outlet flues of the three cyclone separators all lead into the tail flue 105 of the boiler.

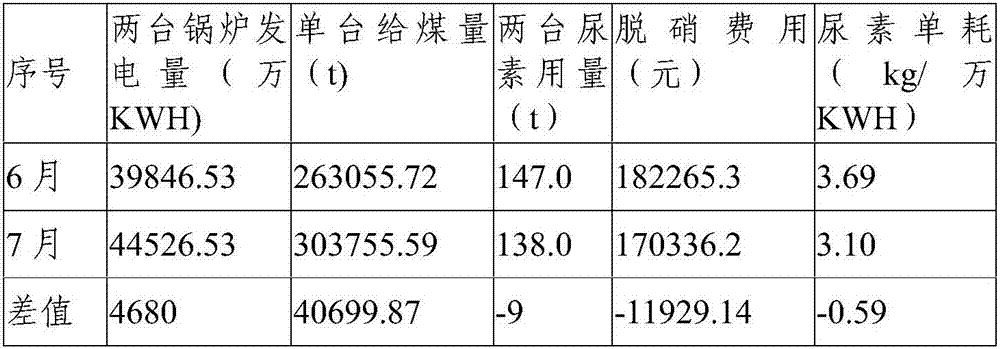

[0053] Before the transformation, a second group of 5 ammonia lances was installed on the inlet flue of the cyclone separator. The cross-sections of the inlet flues of the three cyclones were all rectangular. 2 side ammonia guns 303 are installed up and down, and 1 inlet flue top ammonia gun 302 is installed on the top surface. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com