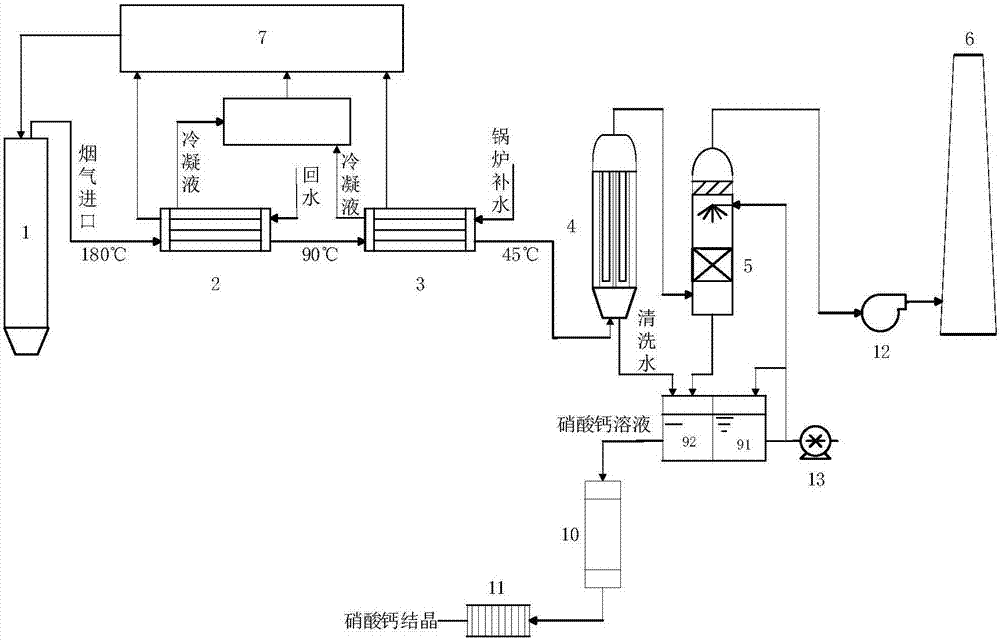

Gas industrial boiler energy saving and smoke deep purification integrated processing system and method

A technology for deep flue gas purification and industrial boilers, which is applied in the field of air pollution control, can solve the problems of general NOx removal effect, failure to meet emission standards, and insufficient stability of low-nitrogen combustion technology, and achieve non-selectivity, low cost, and no pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Utilize the method and system of the present invention to treat the flue gas of the gas-fired water boiler whose rated thermal power is 1.4MW, when the flue gas flow rate is 20m 3 / h, the flue gas temperature is 158°C, the difference between the flue gas moisture content and the air moisture content is 11.30%, and the flue gas NOx concentration is 108.50mg / m 3 , when the ambient temperature is 20°C, after the flue gas passes through the two-stage heat exchanger, the temperature, the difference between the humidity content and the air humidity content, and the NOx concentration can be reduced to 46°C, 3.23% and 65.96mg·m respectively -3 , and the removal rates were 70.89%, 71.42% and 39.21%, respectively.

Embodiment 2

[0043] Utilize the method and system of the present invention to treat the flue gas of the gas-fired water boiler whose rated thermal power is 1.4MW, when the flue gas flow rate is 12m 3 / h, the difference between the moisture content of the flue gas at the inlet of the low-temperature plasma reactor and the moisture content of the air is 3.35%, and the NOx concentration is 41.26mg / m 3 , when the plasma discharge power is 50W, the difference between the moisture content of flue gas and air and the concentration of NOx can finally be reduced to 0.29% and 10.41mg / m3 respectively 3 , and the removal rates were 91.34% and 74.77%, respectively.

Embodiment 3

[0045] Utilize the method and system of the present invention to treat the flue gas of the gas-fired water boiler whose rated thermal power is 1.4MW, when the flue gas flow rate is 10m 3 / h, the flue gas temperature is 198°C, the difference between the flue gas moisture content and the air moisture content is 12.51%, and the flue gas NOx concentration is 167.07mg / m 3 , flue gas SO 2 The concentration is 63.68mg / m 3 , when the ambient temperature is 29°C and the plasma discharge power is 30W, the flue gas temperature, the difference between the humidity content and the air humidity content, NOx and SO 2 Concentrations can be reduced to 33°C, 0.3%, 21.47mg·m -3 and 7.35 mg·m -3 , and the removal rates were 83.33%, 97.6%, 87.39% and 88.46%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com