Efficient and energy-saving heat supply system adopting heat-conducting oil conduction

A heating system, high-efficiency and energy-saving technology, applied in heating systems, electric heating systems, heating fuels, etc., can solve the problems of fragile vacuum glass tubes, furnace ash garbage, air pollution, etc., and achieve low equipment investment and high heat utilization The effect of high efficiency and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

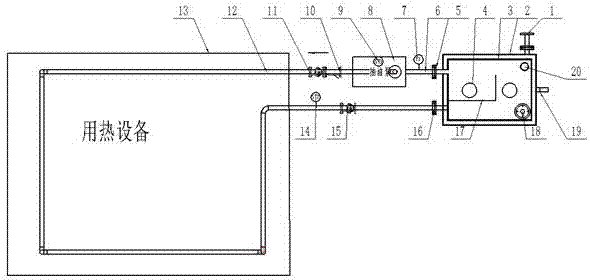

[0020] As shown in the figure, it is a schematic diagram of the structure and composition of the heat transfer system of the present invention. The outer tank 2 of the heat transfer oil tank is filled with thermal insulation cotton, so that the heat transfer oil in the inner tank 3 of the oil tank is heated by the heat transfer oil heating tube 4, so that the oil in the oil tank reaches the set value. Fixed temperature, and can control the temperature, over-temperature alarm. Through the oil pump 8, the oil in the oil tank is output through the oil outlet 5 of the oil tank, and the outlet pressure of the oil tank can be observed through the pressure gauge 7. After passing through the oil well pump 8, the oil outlet explosion-proof thermometer 9 can monitor the temperature of the oil outlet pipe at any time, and through the Y-type filter 10 Filter impurities and enter the heating equipment pipeline 12 through the ball valve 11 to reach the heating equipment 13. The heating equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com