Energy-saving and environment-friendly PVC coating heating furnace

An energy-saving and environment-friendly heating furnace technology, which is applied in lighting and heating equipment, furnaces, incinerators, etc., can solve the problems of high waste rate of PVC products, uneven heating of molds, difficult treatment of organic waste gas, etc., to achieve complete catalytic decomposition, Uniform and stable temperature and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

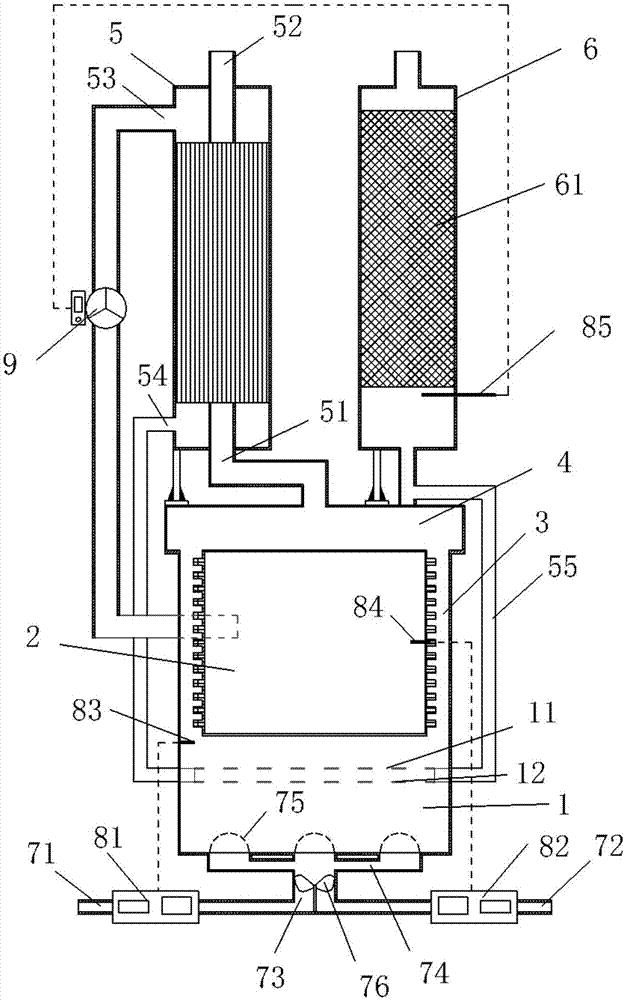

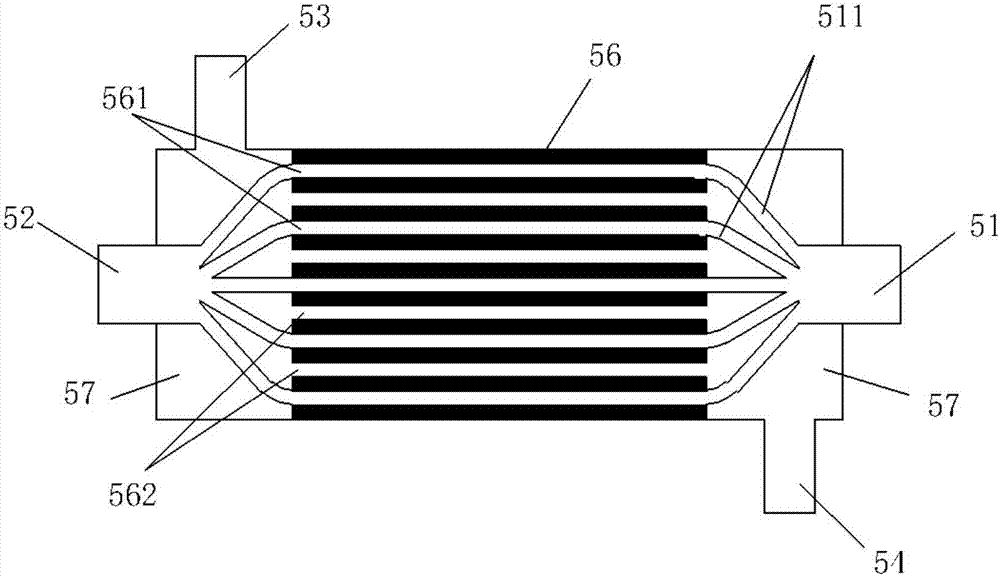

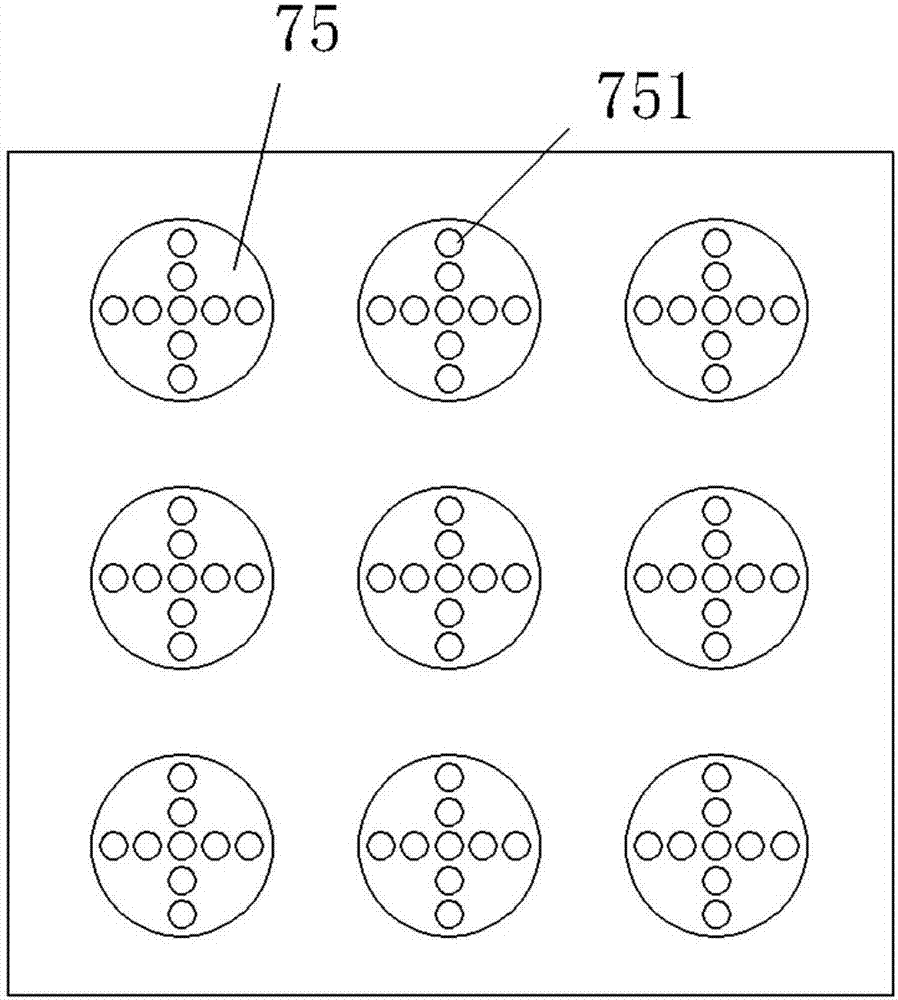

[0021] An energy-saving and environment-friendly plastic dipping heating furnace, comprising a combustion chamber 1, a heating chamber 2, a heating flue 3 and a flue exhaust 4, the heating chamber 2 is arranged above the combustion chamber 1, and heating fumes are arranged on opposite sides of the heating chamber 2 3, the bottom of the heating flue 3 communicates with the combustion chamber 1, and the top of the heating flue 3 gathers in the flue exhaust duct 4 set on the top of the heating chamber 2, which is characterized in that a flue gas heat exchanger 5 is arranged above the flue exhaust duct 4 The heat mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com