Common-optical path self-calibrating thin film thickness measuring device and measuring method

A film thickness and measuring device technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of thin film surface morphology damage, difficult demodulation, etc., to improve absolute accuracy, test stability, and large dynamic range. , to achieve the effect of self-calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

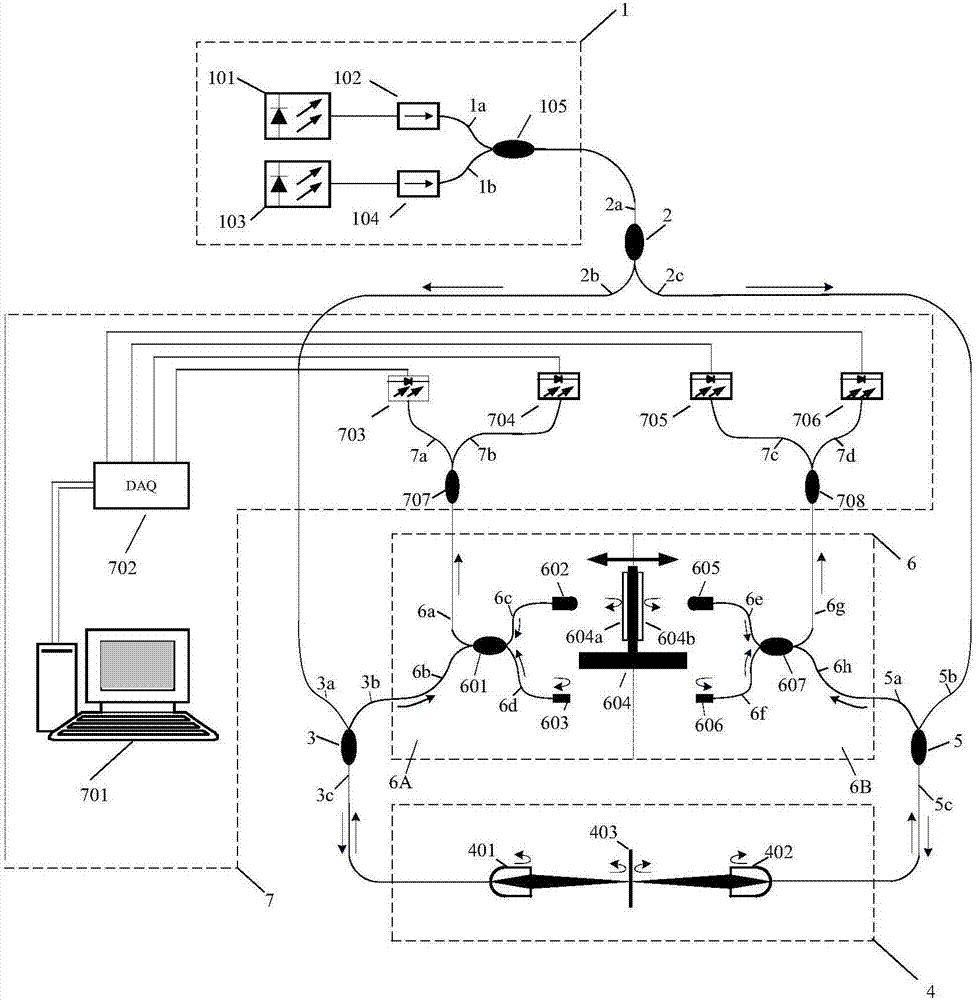

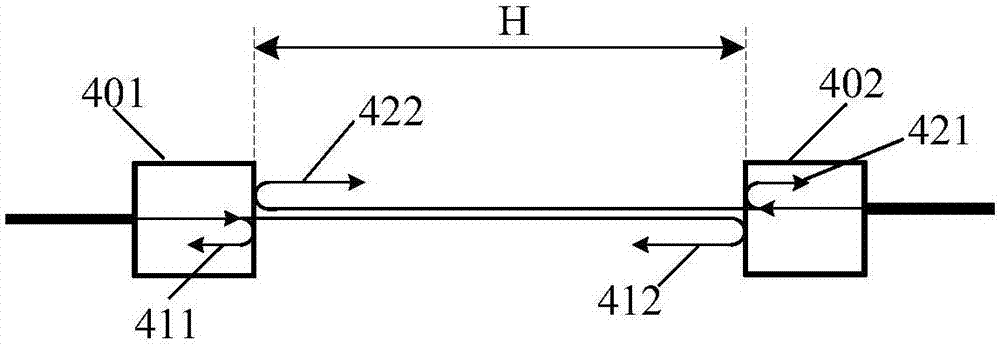

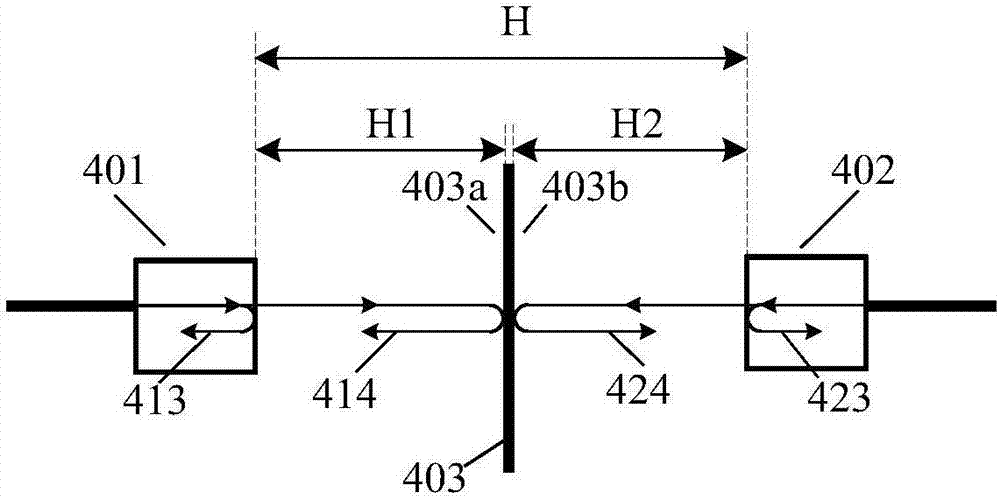

[0030] The common optical path self-calibration film thickness measurement device of the present invention is composed of four parts: a light source output module 1 , a film thickness measurement probe module 4 , an interference and demodulation module 6 , and an acquisition and control module 7 . The components of each module are: (1) The light source output module 1 is composed of a wide-spectrum light source 101, a first isolator 102, a narrowband frequency-stabilized laser light source 103, a second isolator 104, and a first wavelength division multiplexer 105; 2) The film thickness measuring probe module 4 is composed of the first measuring probe 401 and the second measuring probe 402; (3) the interference and demodulation module 6 is composed of the first demodulating interferometer coupler 601, the first collimating mirror 602, The first Faraday mirror 603, the position scanning device 604, the forward movable optical mirror 604a, the reverse movable optical mirror 604b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com