Equipment automatically detecting resistance, voltage and displacement

An automatic detection and equipment technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of increasing the workload of operators and the inability to realize automatic detection of equipment, etc., achieve the effect of humanized parameter setting, convenient and fast operation mode, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

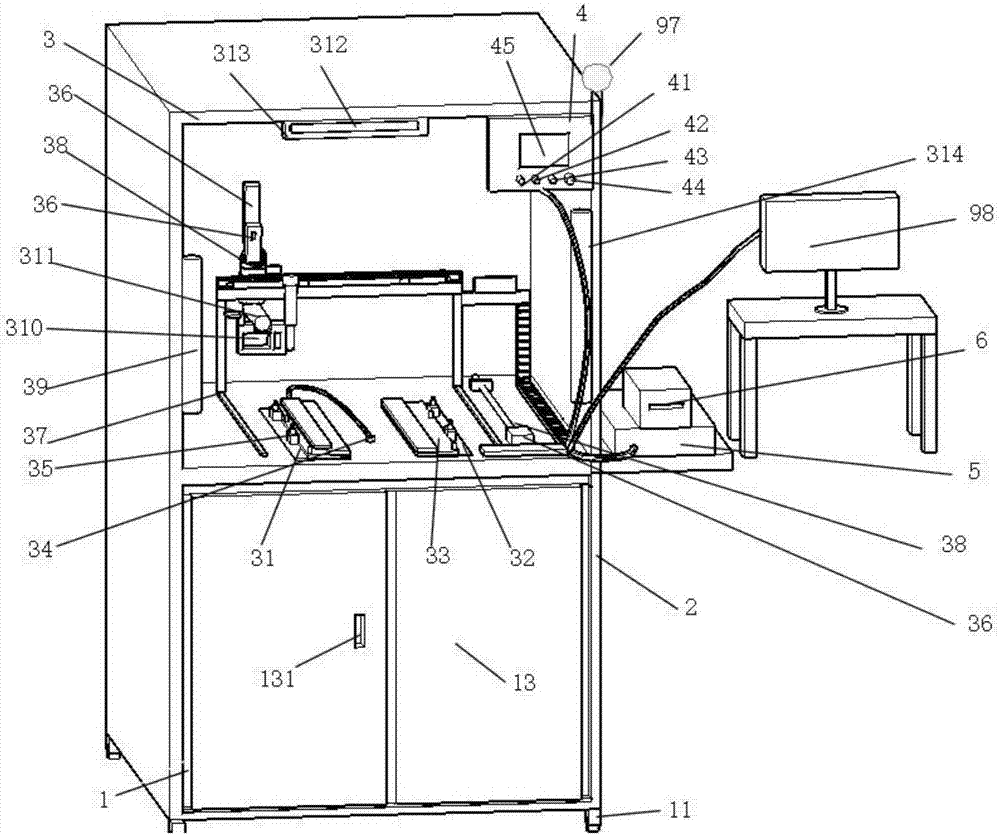

[0088] Please see attached figure 1 , figure 1 It is a three-dimensional structural schematic diagram of a device for automatically detecting resistance-voltage-displacement of the present invention. A device for automatically detecting resistance-voltage-displacement, the device for automatically detecting resistance-voltage-displacement includes a device main frame 1, a lower frame 2, an upper frame 3, and a liquid crystal display operation screen 4; the device main frame 1 Including mobile casters 11, warning lights 12; the lower frame 2 includes an electric control box door 13; the electric control box door 13 is provided with a door lock 131; the upper frame 3 includes a left tooling fixture 31, Right tooling fixture 32, product placement plane 33, resistance test plug 34, pre-press cylinder 35, servo motor 36, guide rail slider 37, transplanting module 38, safety light curtain 39, pressure sensor 310, angle adjustment module 311, LED lighting 312, protective cover 313,...

Embodiment 2

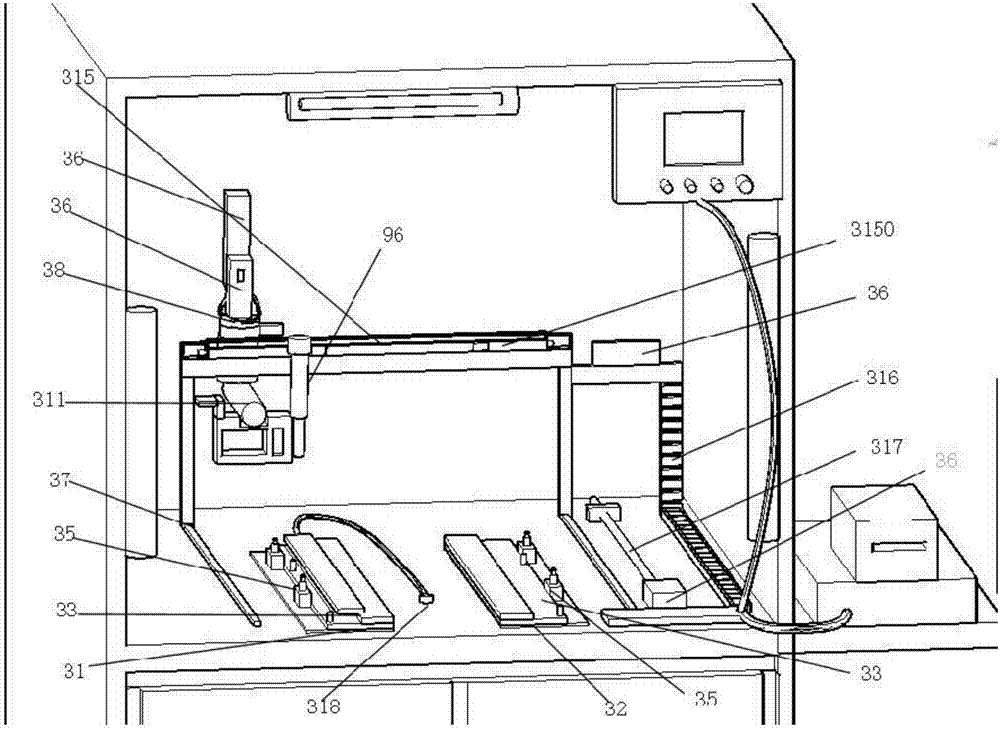

[0091] Please see attached figure 2 , figure 2 It is a schematic diagram of the three-dimensional structure of the upper frame main body of a device for automatically detecting resistance-voltage-displacement of the present invention. This embodiment is basically the same as Embodiment 1, except that the transplanting module 38 provided in the overall structure of the pressure sensor 310 in this embodiment is a Z transplanting module 320 . By supporting the X transplanting platform on the gantry 310 and the provided Y transplanting platform and Z transplanting module, the three can well control the detection range of the pressure sensor 310 . The pressure sensor 310 is provided with an OKNG mark 96, which can better control the pressure range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com