Pixel circuit and driving method of pixel circuit

A pixel circuit and transistor technology, applied in static indicators, instruments, etc., can solve the problems of inconsistency in the writing of the screen signal of the display screen, narrowing of the line width of the pixel circuit planning diagram, and uneven voltage threshold of the pixel circuit, etc., to achieve Conducive to layout, simple circuit layout, uniform display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

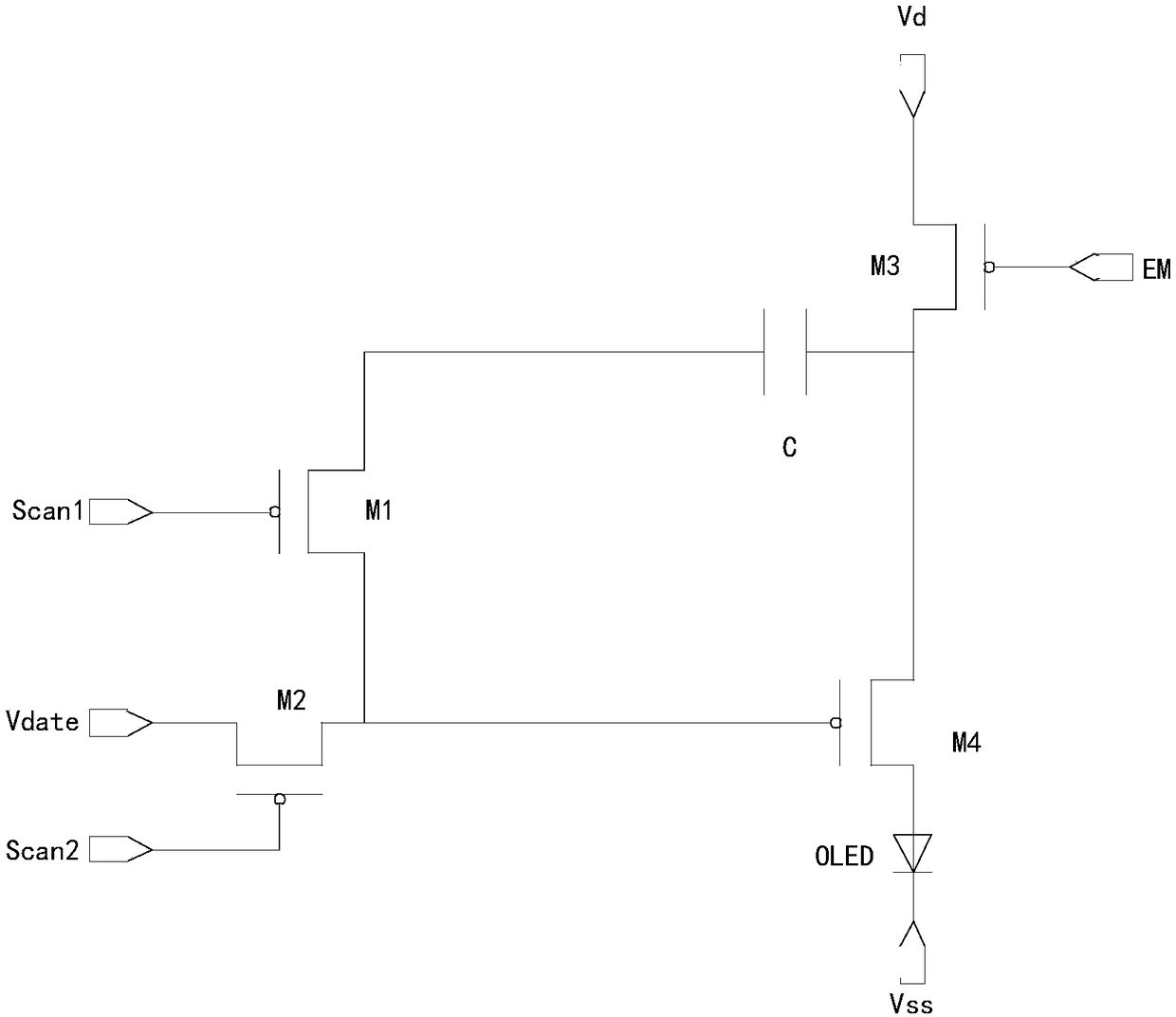

[0031] An embodiment of the present invention provides a pixel circuit, such as figure 1 As shown, the pixel circuit includes a first transistor M1, a second transistor M2, a third transistor M3, a fourth transistor M4, a first scanning signal line Scan1, a second scanning signal line Scan2, a data signal line Vdate, a control signal line EM, capacitor C, power supply and light emitting diode OLED.

[0032] In this embodiment, the gate of the first transistor M1 is connected to the first scanning signal line Scan1, the source of the first transistor M1 is electrically connected to the first plate of the capacitor C, and the first transistor The drain of M1 is connected to the source of the second transistor M2.

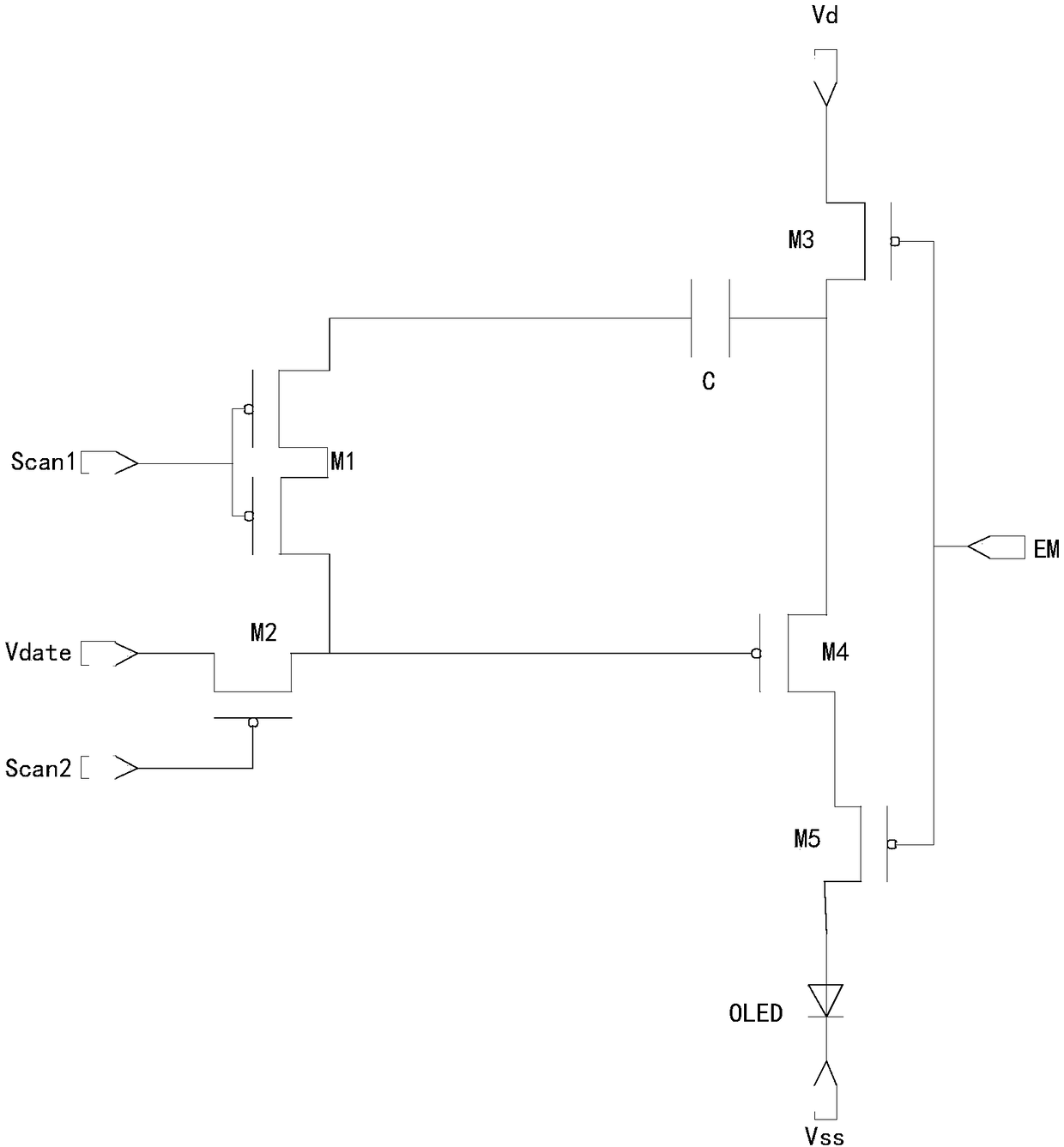

[0033] In one embodiment, as image 3 Said, the first transistor M1 may be a double-gate transistor, and the double gates of the first transistor M1 are both connected to the first scanning signal line Scan1. The leakage current can be effectively reduced by using ...

no. 2 example

[0056] This embodiment provides a pixel circuit. This embodiment is similar to the first embodiment, and the difference is that the pixel circuit in this embodiment has a fifth transistor M5 added to the pixel circuit in the first embodiment. Specific as image 3 As shown, the pixel circuit further includes a fifth transistor M5.

[0057] In this embodiment, the fifth transistor M5 is connected between the fourth transistor M4 and the light emitting diode OLED, and the source of the fifth transistor M5 is connected to the drain of the fourth transistor M4, so The drain of the fifth transistor M5 is grounded, and the gate of the fifth transistor M5 is connected to the control signal line EM; the control signal line EM sends a control signal to the gate of the fifth transistor M5 to control The fifth transistor M5 is turned on or off.

[0058] For other details in this embodiment, reference may be made to the description in the first embodiment, which will not be repeated here...

no. 3 example

[0061] This embodiment provides a pixel circuit. This embodiment is similar to the first embodiment. The difference is that the pixel circuit in this embodiment has a sixth transistor M6 and a reference voltage flat signal line. For details, please refer to Figure 5 , the pixel circuit further includes a sixth transistor M6 and a reference level signal line.

[0062] In this embodiment, the gate of the sixth transistor M6 is connected to the first scanning signal line Scan1, and the drain of the sixth transistor M6 is connected to the light-emitting diode OLED; the first scanning signal line Scan1 sends A control signal is sent to the gate of the sixth transistor M6 to control the sixth transistor M6 to be turned on or off.

[0063] The reference level signal line is connected to the source of the sixth transistor M6, and the reference level signal line is used to provide an initial current to flow into the light emitting diode OLED through the sixth transistor M6 to initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com