High-vicat anticorrosion high-strength CPVC (chlorinated polyvinyl chloride) plate and preparation method thereof

A corrosion-resistant, high-vicat technology, applied to high-strength CPVC sheets and their preparation, corrosion-resistant, high-vicat fields, can solve problems such as high prices, limited promotion and use, and late start of CPVC research and development, and achieve good market competition The effect of power and price concessions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

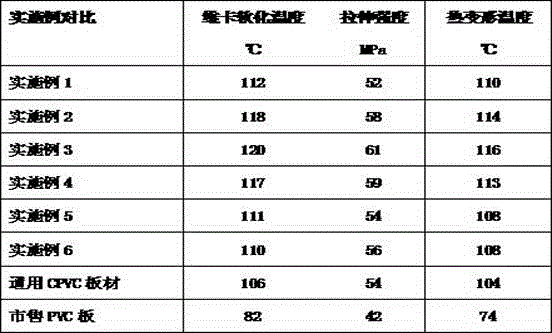

[0043] Embodiment 1, a kind of high-vicat, corrosion-resistant, high-strength CPVC sheet material, the Vicat softening temperature of described CPVC sheet material is at 112

[0044] ℃, the tensile strength is 52MPa, and the heat distortion temperature is 110℃.

[0045] The CPVC plate is composed of the following raw materials in parts by weight:

[0046] CPVC resin: 100 parts of CPVC resin with a chlorine content of 70% and a degree of polymerization of 600;

[0047] PVC resin S-700, 5 parts;

[0048] Heat stabilizer: 5 parts of calcium-zinc composite stabilizer;

[0049] Auxiliary stabilizer: 1.2 parts of epoxidized soybean oil;

[0050] 1 part of pentaerythritol stearate;

[0051] External lubricant: 1.4 parts of Fischer-Tropsch wax;

[0052] Internal lubricant: 1.3 parts of stearic acid;

[0053] Processing aid: ACR401, 1.8 parts;

[0054] Impact modifier: 3 parts of MBS resin;

[0055] Filler: 5 parts of white carbon black;

[0056] Pigment: 0.03 parts of carbon ...

Embodiment 2

[0058] Embodiment 2, a kind of high-vicat, corrosion-resistant, high-strength CPVC sheet material, the Vicat softening temperature of described CPVC sheet material is at 118

[0059] ℃, the tensile strength is 58MPa, and the heat distortion temperature is 114℃.

[0060] The CPVC plate is composed of the following raw materials in parts by weight:

[0061] CPVC resin: 100 parts of CPVC resin with a chlorine content of 71% and a degree of polymerization of 600;

[0062] PVC resin S-700, 5 parts;

[0063] Heat stabilizer: 5 parts of rare earth composite stabilizer;

[0064] Auxiliary stabilizer: 0.5 part of epoxidized soybean oil;

[0065] 1.2 parts of pentaerythritol stearate;

[0066] External lubricant: 2.5 parts of PE wax;

[0067] Internal lubricant: 1 part of OPE wax;

[0068] Processing aid: ACR401, 2 parts;

[0069] Impact modifier: CPE135A, 5 parts;

[0070] Filler: 3 parts of titanium dioxide.

[0071] The CPVC resin is prepared by combining an initiator and ul...

Embodiment 3

[0072] Embodiment 3, a high-Vicat, corrosion-resistant, high-strength CPVC plate, the Vicat softening temperature of the CPVC plate is 120°C, the tensile strength is 61MPa, and the heat distortion temperature is 116°C.

[0073] The CPVC plate is composed of the following raw materials in parts by weight:

[0074] CPVC resin: 100 parts of CPVC resin with a chlorine content of 72% and a degree of polymerization of 600;

[0075] PVC resin S-700, 10 parts;

[0076] Heat stabilizer: 3 parts of calcium-zinc composite stabilizer, 3 parts of rare earth composite stabilizer;

[0077] Auxiliary stabilizer: 0.8 parts of epoxidized soybean oil;

[0078] 2 parts of pentaerythritol stearate;

[0079] External lubricant: 1 part of PE wax;

[0080] Internal lubricant: 1 part of calcium stearate;

[0081] Processing aid: ACR201, 1.5 parts;

[0082] Impact modifier: impact-resistant ASA, 1.5 parts;

[0083] Filler: 6 parts of white carbon black;

[0084] Pigment: 0.06 parts of carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com