Biomass gasification extraction liquid cooling device

A technology of cooling device and extracting liquid, applied in gasification process, cleaning heat transfer device, manufacturing combustible gas, etc., can solve problems such as excessive VOC and reduced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

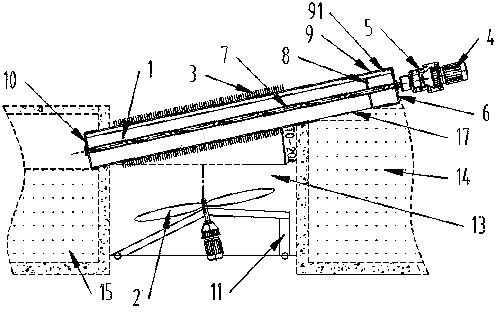

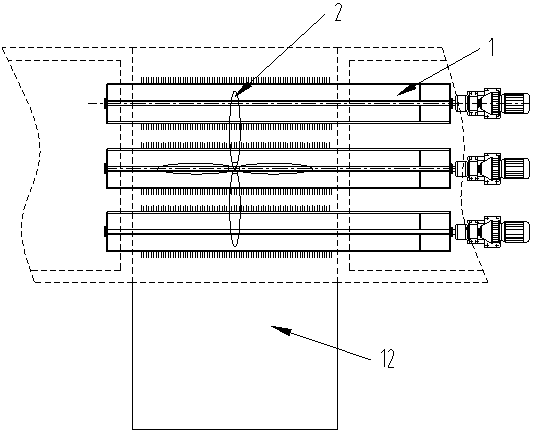

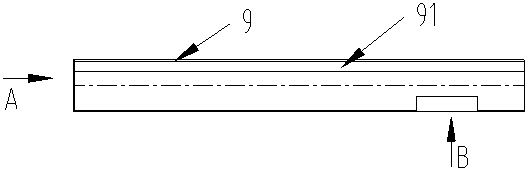

[0021] see figure 1 , 2 In the shown device for cooling the extraction liquid of biomass gasification, the motor 4 is connected with the reducer 5 , and the housing of the reducer is fixed on the bearing seat 6 . The output shaft of the reducer is connected with the intermediate threaded rod 7 , and the other end of the intermediate threaded rod 7 is movably connected with the fixed end 10 . The external thread of the intermediate threaded rod 7 and the internal thread of the threaded pusher plate 8 form a spiral pair. 91 matched guide recess 81, the inner wall of the outer tube 9 coincides with the outer circumference of the threaded push plate 8. Through the rotation of the motor 4, the middle threaded rod 7 is driven to rotate, and then the threaded push plate 8 will move axially along the outer tube 9, pushing the tar accumulated on the tube wall to flow out from the outlet of the extraction solution of the outer tube 9, thereby Clean the inner wall of the outer tube 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com