Sweet-scented low-fat peanut milk

A peanut milk, low-fat technology, applied in the direction of milk preparations, dairy products, applications, etc., to achieve the effect of improving functions, full of strong aroma and taste, and natural taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

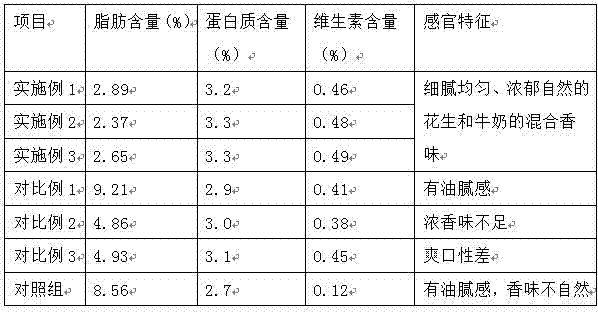

Examples

Embodiment 1

[0014] A kind of thick-flavored low-fat peanut milk, which is made of the following raw materials in parts by weight: 400 parts of fresh milk, 60 parts of peanuts, 20 parts of soybeans, 20 parts of sweet corn kernels, 10 parts of cucumbers, 0.5 parts of grape seed powder, fermented 0.8 part of agent, 0.1 part of stabilizer, the starter is prepared by lactic acid bacteria strain through strain activation and expanded culture, and the stabilizer contains the following ingredients in mass percentage: sodium alginate 30%, carboxymethyl cellulose 30% plain sodium, 5% sodium chloride, and the rest is carrageenan.

[0015] As a further improvement to the above scheme, its preparation method comprises the following steps:

[0016] (1) Remove the seed coat from the clean peanuts, crush them into powder, stir-fry the crushed peanuts at 120°C for 5 minutes, then press them to separate the peanut oil and residue, and add 3 times the volume of water to the residue , use high heat to heat,...

Embodiment 2

[0021] A kind of thick-flavored low-fat peanut milk, which is made of the following raw materials in parts by weight: 425 parts of fresh milk, 70 parts of peanuts, 25 parts of soybeans, 22 parts of sweet corn kernels, 12 parts of cucumbers, 0.7 parts of grape seed powder, fermented 0.9 part of agent and 0.15 part of stabilizer. The starter is prepared by lactic acid bacteria strain through strain activation and expanded culture. The stabilizer contains the following components in mass percentage: 35% sodium alginate, carboxymethyl cellulose 35% of plain sodium, 5% of sodium chloride, and the rest is carrageenan.

[0022] As a further improvement to the above scheme, its preparation method comprises the following steps:

[0023] (1) Remove the seed coat from the clean peanuts, crush them into powder, stir-fry the crushed peanuts at 135°C for 7 minutes, and then squeeze them to separate the peanut oil and residue, add 4 times the volume of water to the residue , use high heat t...

Embodiment 3

[0028] A kind of thick-flavored low-fat peanut milk, which is made of the following raw materials in parts by weight: 450 parts of fresh milk, 80 parts of peanuts, 30 parts of soybeans, 25 parts of sweet corn kernels, 15 parts of cucumbers, 1.0 parts of grape seed powder, fermented 1.0 part of agent and 0.2 part of stabilizer. The starter is prepared by lactic acid bacteria strain through strain activation and expanded culture. The stabilizer contains the following ingredients in mass percentage: 40% sodium alginate, carboxymethyl cellulose 40% plain sodium, 10% sodium chloride, and the rest is carrageenan.

[0029] As a further improvement to the above scheme, its preparation method comprises the following steps:

[0030] (1) Remove the seed coat from the clean peanuts, crush them into powder, stir-fry the crushed peanuts at 150°C for 10 minutes, then squeeze them to separate the peanut oil and residue, and add 5 times the volume of water to the residue , use high heat to he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com