Shelling and separation method of toxicodendron succedaneum seeds

A separation method and tree seed technology, applied in the field of fruit separation, can solve the problems such as the greater influence of the extraction of wild sumac seeds, and achieve the effect of good shelling and separation, and good shelling and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

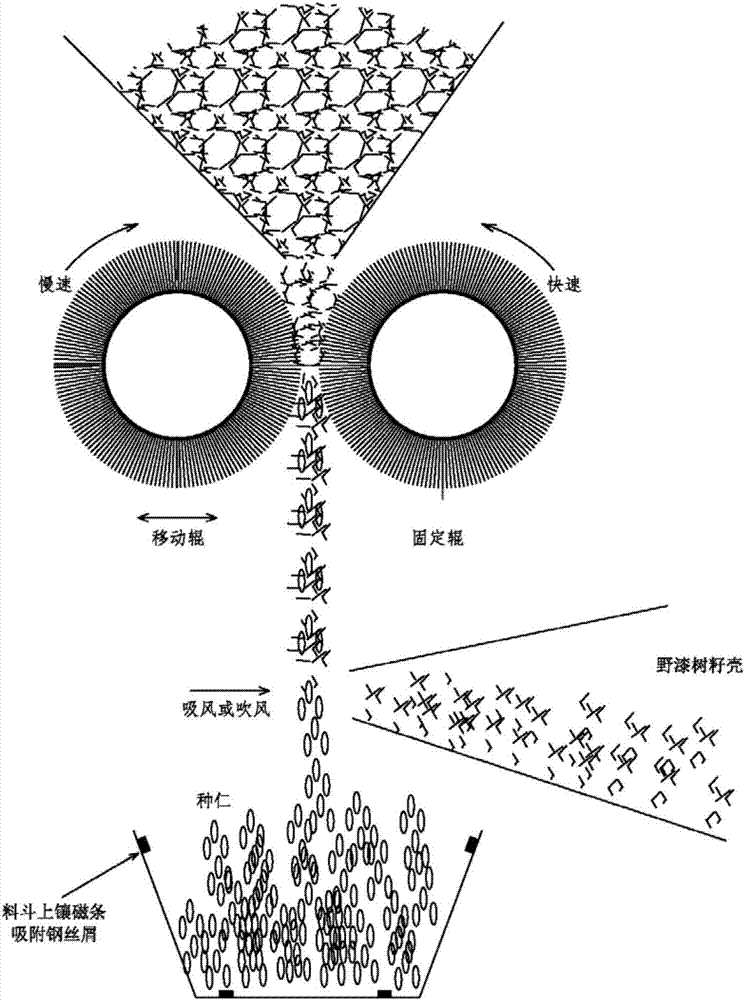

[0022] This embodiment provides a method for shelling and separating wild sumac seeds, which specifically includes the following steps (combined figure 1 ):

[0023] The first step: the pretreatment of the wild sumac seeds: the wild sumac seeds are dried before being hulled, and the moisture content is less than 6%;

[0024] Step 2: Shelling the wild sumac seeds:

[0025] The main working part is a pair of steel wire brush rollers; the axes of the two rollers are in the same horizontal plane or have a slight height difference; the two rollers rotate at different speeds, and there is a linear speed difference between the two rollers; the wild lacquer seeds are evenly fed between the two rollers , The equal-diameter rollers rotate at different linear speeds, and the wild lacquer seeds passing between the rollers are squeezed by the two rollers and rubbed and teared by the difference in speed between the two rollers to achieve the purpose of shelling;

[0026] The third step: Separation...

Embodiment 2

[0031] This embodiment is a further application of the method provided in embodiment 1. In the hulling and separation, the two rollers rotate at different speeds in the second step, and the difference between the linear speeds of the two rollers is 1.5-2 m / s; third During the step, blow in or suck out the wild sumac seed husk at a wind speed of 3 to 5 m / s; there is almost no wild sumac seed husk residue in the final separated seed kernels, and at the same time, it can be adsorbed after installing magnets at the bottom of the hopper and the discharge port A large number of steel chips, the adsorption rate of steel chips reached more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com