Method for achieving sewage treatment continuous short-term nitrification and denitrification through sludge fermentation products

A technology for sewage treatment and short-range nitrification, applied in water/sludge/sewage treatment, biological water/sewage treatment, chemical instruments and methods, etc. Effect of processing fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

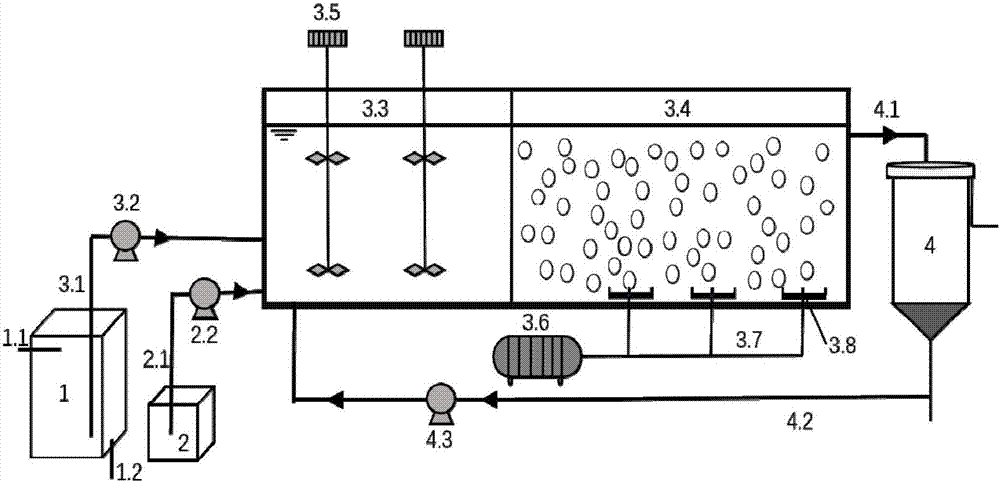

[0021] The system for realizing continuous flow short-path nitrification and denitrification of sewage treatment through sludge fermentation product is characterized in that it includes a sewage raw water tank (1), a sludge fermentation product storage tank (2), and a sewage treatment continuous flow reactor (3) (in the form of A / O reactor is an example), sedimentation tank (4); sewage raw water tank (1) includes overflow pipe (1.1) and vent pipe (1.2); sewage raw water tank (1) and sludge fermentation product storage tank ( 2) connected to the sewage treatment continuous flow reactor (3) through the water inlet pipe (3.1), the water inlet pump (3.2), the sludge fermentation product feeding pipe (2.1), and the sludge fermentation product feeding pump (2.2); The continuous flow reactor (2) (taking the A / O process as an example) includes the anoxic section (3.3) and the aerobic section (3.4). The water flow hole is connected; the aerobic section (3.4) adopts the air pump (3.6), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com