Antimony-containing wastewater treatment technology

A wastewater treatment and process technology, applied in textile industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of high cost, secondary pollution, long treatment time, etc., to reduce dosage and improve response speed , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

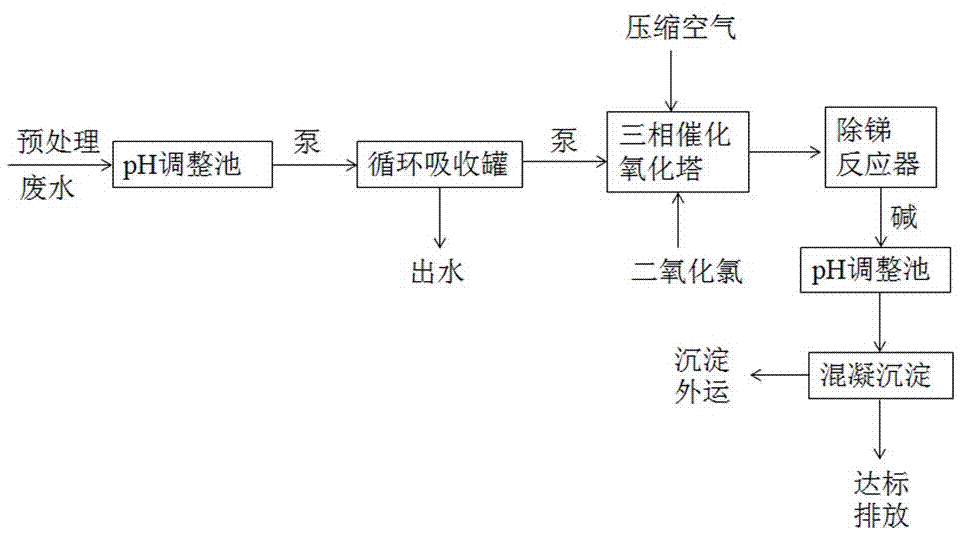

[0036] Such as figure 1 As shown, the pretreated antimony-containing wastewater enters the pH adjustment tank, adjusts its pH value to 5.0-6.0, and pumps it to the filter through a pump to remove suspended solids in the wastewater, preventing pollution and clogging of the subsequent three-phase catalytic oxidation tower efficient catalyst. The effluent from the filter enters the circulation absorption tank, which continuously mixes the chlorine dioxide produced by the chlorine dioxide generator into the antimony-containing wastewater, and after being fully mixed in the circulation absorption tank, it enters the three-phase catalytic oxidation tower. Under the action of the high-efficiency catalyst in the three-phase catalytic oxidation tower, chlorine dioxide and oxygen in the compressed air remove the refractory organic matter in the wastewater through the oxidation reaction, reduce the COD in the wastewater, and remove the chroma of the wastewater. The wastewater after cata...

Embodiment 2

[0043] Such as figure 1As shown, the pretreated antimony-containing wastewater enters the pH adjustment tank, adjusts its pH value to 5.5-6.5, and pumps it to the filter to remove suspended solids in the wastewater, preventing pollution and clogging of the subsequent three-phase catalytic oxidation tower efficient catalyst. The effluent from the filter enters the circulation absorption tank, which continuously mixes the chlorine dioxide produced by the chlorine dioxide generator into the antimony-containing wastewater, and after being fully mixed in the circulation absorption tank, it enters the three-phase catalytic oxidation tower. Under the action of the high-efficiency catalyst in the three-phase catalytic oxidation tower, chlorine dioxide and oxygen in the compressed air remove the refractory organic matter in the wastewater through the oxidation reaction, reduce the COD in the wastewater, and remove the chroma of the wastewater. The wastewater after catalytic oxidation ...

Embodiment 3

[0050] Such as figure 1 As shown, the pretreated antimony-containing wastewater enters the pH adjustment tank, adjusts its pH value to 6.0-7.0, and pumps it to the filter to remove suspended solids in the wastewater, preventing pollution and clogging of the subsequent three-phase catalytic oxidation tower efficient catalyst. The effluent from the filter enters the circulation absorption tank, which continuously mixes the chlorine dioxide produced by the chlorine dioxide generator into the antimony-containing wastewater, and after being fully mixed in the circulation absorption tank, it enters the three-phase catalytic oxidation tower. Under the action of the high-efficiency catalyst in the three-phase catalytic oxidation tower, chlorine dioxide and oxygen in the compressed air remove the refractory organic matter in the wastewater through the oxidation reaction, reduce the COD in the wastewater, and remove the chroma of the wastewater. The wastewater after catalytic oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com