Self-defoaming polyvinyl alcohol prepared through chemical modification, and preparation method thereof

A polyvinyl alcohol, chemical modification technology, applied in the field of modified polyvinyl alcohol, chemically modified polyvinyl alcohol with defoaming function, can solve the problems of SPVC quality decline, fish eye number increase, output reduction, etc., to achieve The effect of reducing the pressure of sewage treatment, regular physical form, and advanced processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

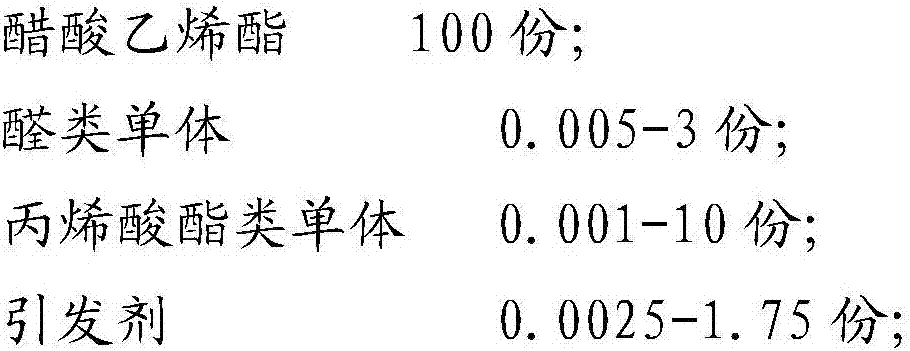

Method used

Image

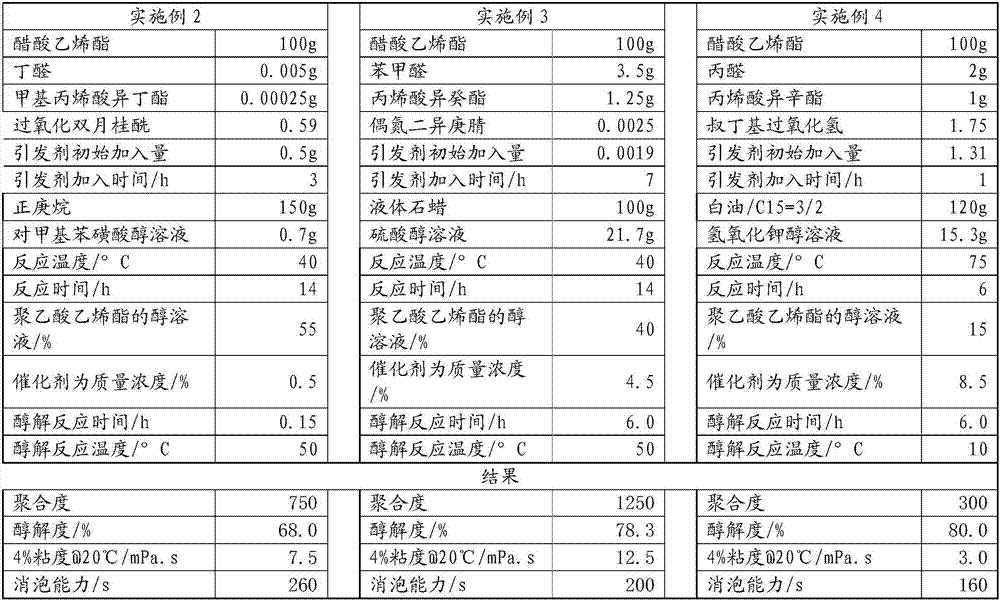

Examples

Embodiment 1

[0034] After replacing the air with nitrogen in a 2-liter stirred polymerization tank, add 100g of vinyl acetate (VAM), 80g of methanol, 1.5g of acetaldehyde, 2.5g of isopropyl acrylate and 1g of α, α-azo Diisoheptylnitrile was used as the initiator. Start stirring, heat the reactor, heat up to 55°C for 10 minutes and then heat up to 65°C for polymerization, then inject 40 g of methanol solution containing 0.5wt% α, α-azobisisoheptanonitrile through a syringe pump, and the injection time is 6 hours, the total reaction time was terminated after 12 hours. After the polymerization, the temperature is raised to evaporate and recover methanol and residual monomers. Methanol was added to the reaction mixture to adjust the content to 30.0 wt%, to obtain polyvinyl acetate (PVAc) to be alcoholysed. Add 100g polyvinyl acetate (PVAc) in a 2 liter tool stirring alcoholysis tank, add 1.25% sodium hydroxide methanol solution equivalent to 8.5 parts by weight of polyvinyl acetate as a cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com