A kind of halogen-free anti-droplet flame-retardant nylon 6 resin and preparation method thereof

A flame-retardant nylon and anti-droplet technology, which is applied in the field of flame-retardant resin and its preparation, can solve the problems of the decline in mechanical properties of nylon 6 materials and the large amount of flame retardant added, and achieve good and longer-lasting flame-retardant effects, flame-retardant high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

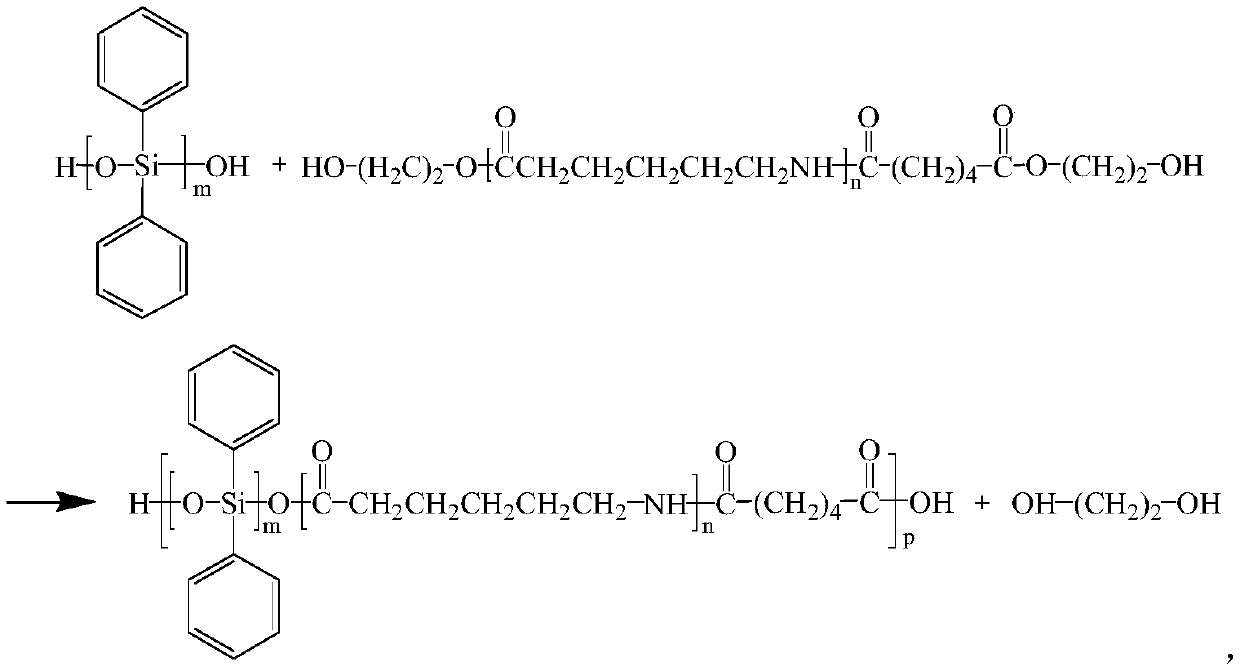

Image

Examples

Embodiment 1

[0040] (a) Preparation of green and environmentally friendly silicon-based flame-retardant oligomers

[0041] Weigh 10 g of diphenylsilanediol (DPSD), 0.135 g of HCl and 50 ml of tetrahydrofuran (THF) and fully dissolve them in a three-necked flask. Stir under the conditions of 25° C. and 800 Pa, and react for 60 hours. After the reaction is complete, the product polyphenylsiloxane (PDPS, m≈4) is obtained.

[0042] (b) Preparation of Nylon 6 Ester

[0043] Step 1: Add 100g of caprolactam, 5g of water, 1g of aminocaproic acid and 16.75g of adipic acid into the reaction kettle, pass nitrogen gas 3 times until the air in the kettle is replaced, and maintain a pressure of 0.025MPa, then raise the temperature to 260 ℃, stirred and reacted for 2 hours; the pressure in the kettle was adjusted to 400Pa, and the reaction was continued at 220℃ for 2 hours to obtain a carboxylated PA6 prepolymer with a molecular weight of 1000.

[0044] Step 2: After the reaction in the first step is c...

Embodiment 2

[0048] (a) Preparation of green and environmentally friendly silicon-based flame-retardant oligomers

[0049] Weigh 10g diphenylsilanediol (DPSD), 0.18g H 2 SO 4and 50ml of N,N dimethylpyrrolidone (NMP) were fully dissolved in a three-neck flask. Stir under the conditions of 80° C. and 200 Pa, and react for 8 hours. After the reaction is complete, the product polyphenylsiloxane (PDPS, m≈4)) is obtained.

[0050] (b) Preparation of Nylon 6 Ester

[0051] Step 1: Add 100g of caprolactam, 2g of water, 4g of aminocaproic acid and 7.8g of adipic acid into the reaction kettle, pass nitrogen gas 3 times until the air in the kettle is replaced, and maintain a pressure of 0.2MPa, then raise the temperature to 260 ℃, stirred and reacted for 2 hours; the pressure in the kettle was adjusted to 200Pa, and the reaction was continued at 240℃ for 2 hours to obtain a carboxylated PA6 prepolymer with a molecular weight of 2000.

[0052] Step 2: After the reaction in the first step is comple...

Embodiment 3

[0056] (a) Preparation of green and environmentally friendly silicon-based flame-retardant oligomers

[0057] Weigh 10g diphenylsilanediol (DPSD), 0.5g AlCl 3 and 50ml of toluene were fully dissolved in a three-necked flask. Stir under the conditions of 50° C. and 100 Pa, and react for 8 hours. After the reaction is complete, the product polyphenylsiloxane (PDPS) is obtained.

[0058] (b) Preparation of Nylon 6 Ester

[0059] Step 1: Add 100g of caprolactam, 4g of water, 2g of aminocaproic acid and 21.72g of adipic acid into the reaction kettle, pass nitrogen gas 3 times until the air in the kettle is replaced, and maintain a pressure of 0.05MPa, then raise the temperature to 240 ℃, stirred and reacted for 2 hours; the pressure in the kettle was adjusted to 300Pa, and the reaction was continued at 240℃ for 2 hours to obtain a carboxylated PA6 prepolymer with a molecular weight of 800.

[0060] Step 2: After the reaction in the first step is completed, adjust the pressure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com