Al-TiB2 pure-phase intermediate alloy with high volume fraction and preparation method thereof

A kind of master alloy, al-tib2 technology, applied in the field of environment-friendly low-cost large volume fraction Al-TiB2 master alloy preparation, can solve the problems of high preparation cost, pollution, poor performance of composite materials, etc., and achieve uniform distribution and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

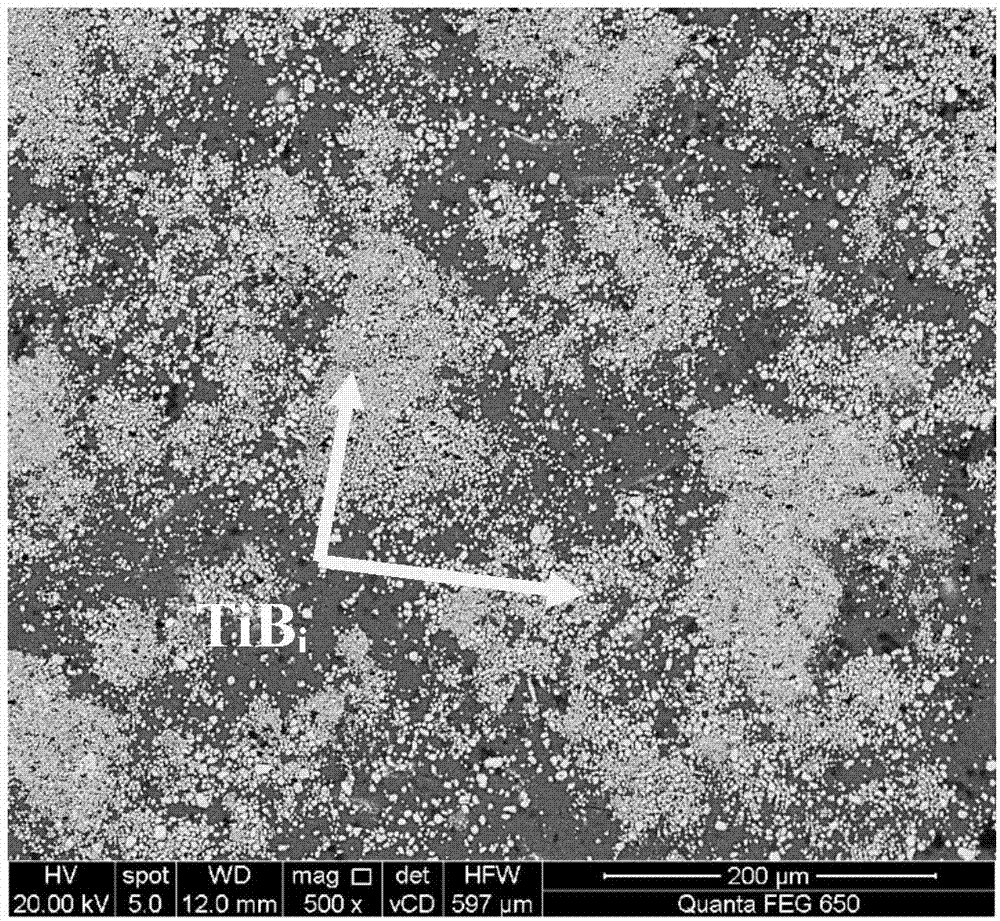

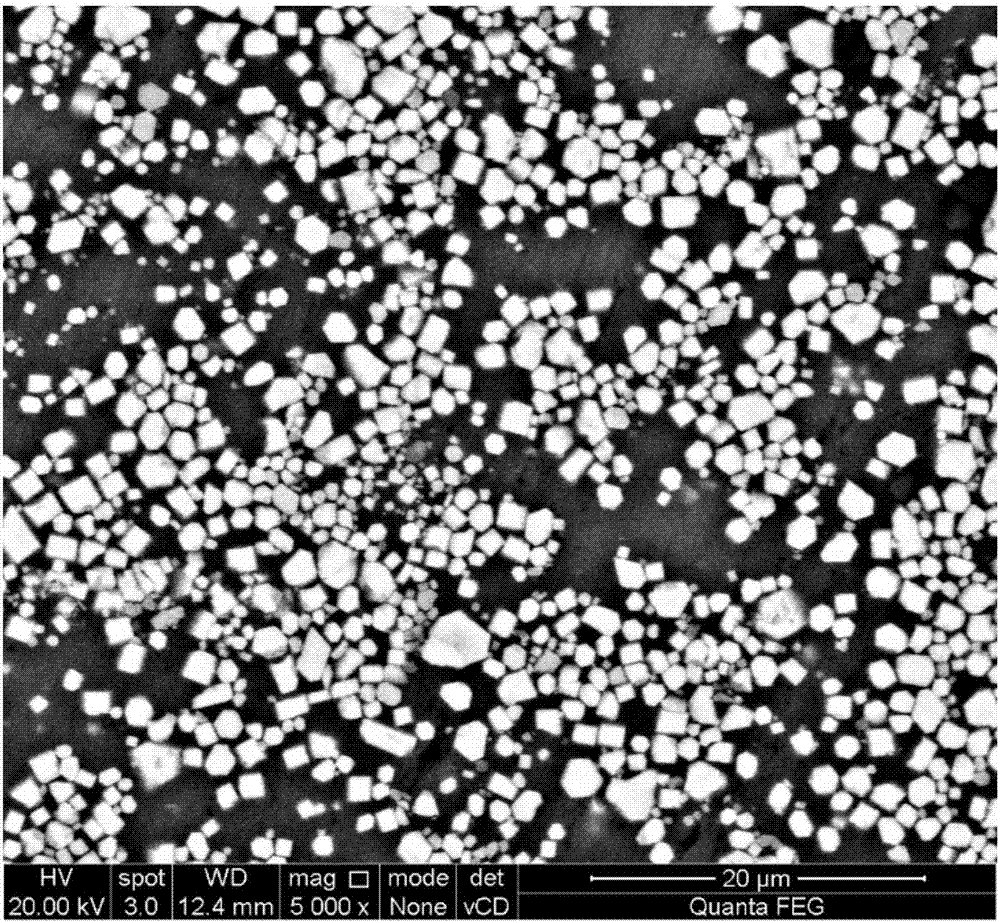

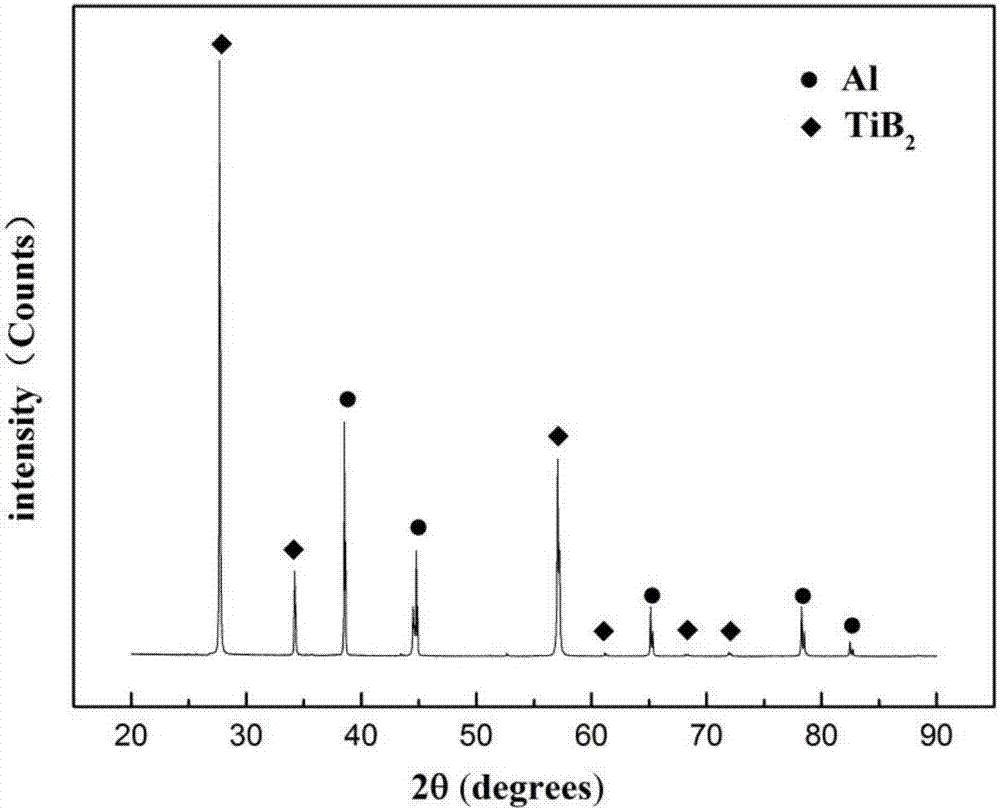

[0022] Preparation of Al-10TiB by Melt Self-propagating Direct Synthesis 2 (TiB 2 The mass percentage composition is 10%) intermediate process is as follows:

[0023] 1. Raw material preparation, refiner by H 3 BO 3 、TiO 2 , aluminum powder, titanium powder, aluminum ingot, C 2 Cl 6 Preparation, wherein the purity of the aluminum ingot is 99.9%.

[0024] 2. Prepare 1Kg of master alloy, weigh H as required 3 BO 3 、TiO 2 , aluminum powder, titanium powder, aluminum ingots, the aluminum burning loss rate is 3%. require H 3 BO 3 : TiO 2 : The molar ratio of Al powder: Ti powder=4:1:4:1, and the rest are Al ingots.

[0025] 3 will H 3 BO 3 、TiO 2 The powder is heated at 200°C for two hours to remove moisture, and the powder is taken out every 30 minutes for stirring to prevent agglomeration.

[0026] 4. Mix the heated powder with titanium powder and aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 15×Φ65mm 3 The cylindrical powder...

Embodiment 2

[0030] Preparation of Al-15TiB by Melt Self-propagating Direct Synthesis 2 (TiB 2 The mass percentage of

[0031] 15%) The intermediate process is as follows:

[0032] 1. Raw material preparation, refiner by H 3 BO 3 、TiO 2 , aluminum powder, titanium powder, aluminum ingot, C 2 Cl 6 Preparation, wherein the purity of the aluminum ingot is 99.9%.

[0033] 2. Prepare 1Kg of master alloy, weigh H as required 3 BO 3 、TiO 2 , aluminum powder, titanium powder, aluminum ingots, the aluminum burning loss rate is 3%. require H 3 BO 3 : TiO 2 : The molar ratio of Al powder: Ti powder=4:1:4:1, and the rest are Al ingots.

[0034] 3 will H 3 BO 3 、TiO 2 The powder is heated at 200°C for two hours to remove moisture, and the powder is taken out every 30 minutes for stirring to prevent agglomeration.

[0035] 4. Mix the heated powder with titanium powder and aluminum powder evenly, put the evenly mixed powder in the mold, and press it into 15×Φ65mm 3 The cylindrical powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com